Concrete, Purusline living wetroom solution, Purus centre linear 800 wet room solution – Purus Living 800 - Drop/Twist Grate User Manual

Page 12: Step 4, Step 2, Step 3

12

PURUSLINE LIVING WETROOM SOLUTION

Concrete

14

PURUS CENTRE LINEAR 800 Wet Room Solution

Concrete

Step 4

Ensure the Tanking Kit is installed as per the Instructions.

Ensure you follow the Tanking Kit instructions and that the tapes and

membranes are fully secure and the concrete floor is primed. The clam-

ping frame is m ounted after the sealing/tanking layer (1).

Position the clamping frame and pierce

holes for the screws with

an awl tool.

Tape/ fabric

membrane

(1)

Gasket

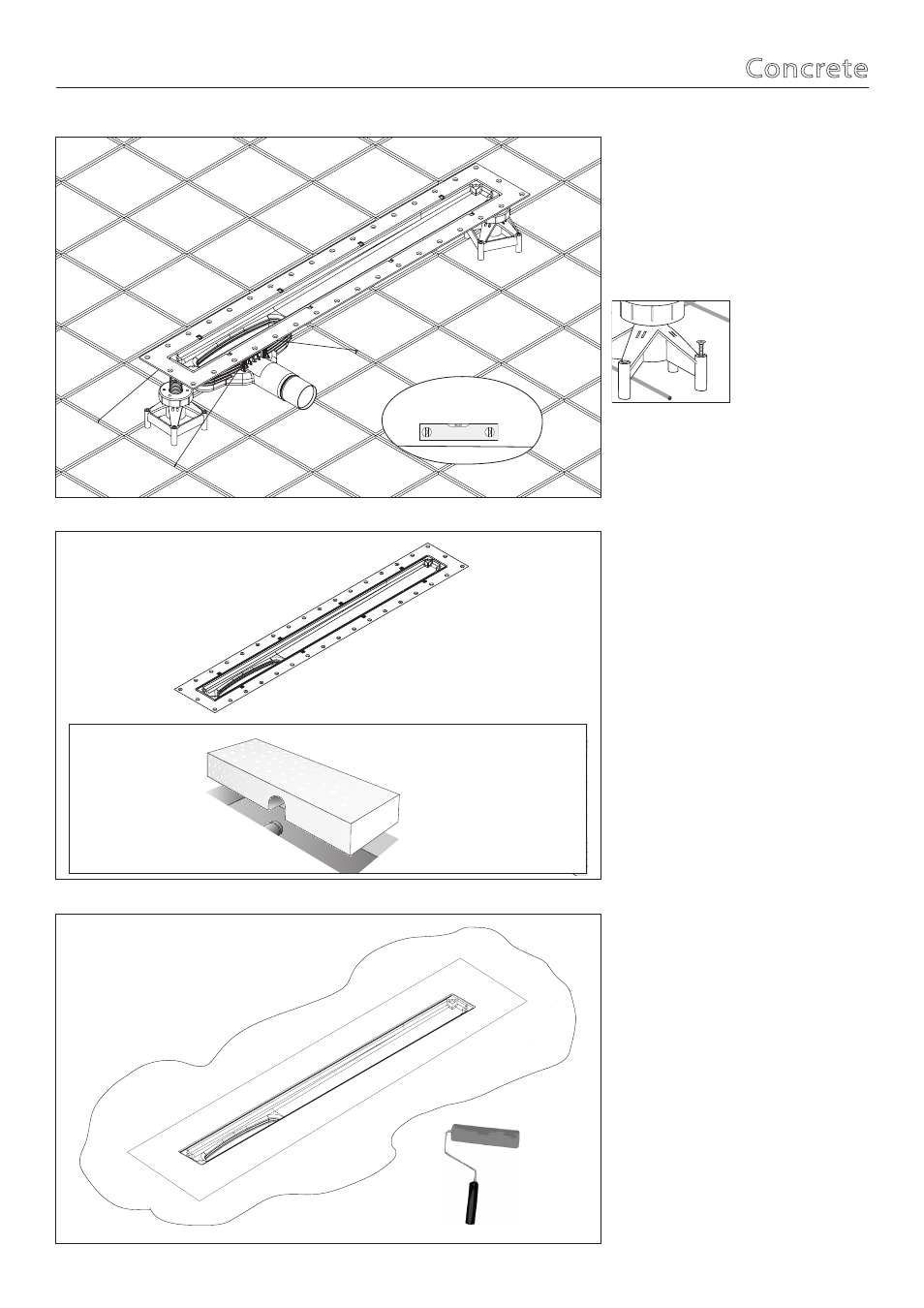

Step 2

Linear wetroom gully is placed

on the surface and the height is

adjusted by PURUS support.

Connect the gully to the waste

pipe. The installation is attached

to the reinforcement with steel

wire.

The concrete

installation

support may

be nailed or

screwed to

the surface.

IMPORTANT:

Leave the protection plastic

on during cementing!

On rough

concrete bed,

the mounting can be fixed with cement

under the gully (fig. B).

(1)

Step 3

The floor is cemented, then primed

and the membrane/tapes (1) is mounted

to the upper part of the channel.

Linear Wetroom 800 gully is installed

on the same level as sealing/tanking

layer.

It must be

installed flat

Gasket

Tape or

fabric membrane

Waste pipes

If your If your waste pipe is an

ABS plastic 1 1/2 inch or 42,9

mm pipe then you can use the

supplied 42.9 mm (1 1/2 inch)

ABS pipe adapter provided for

solvent welding and connecting

to the 42.9 mm (1 1/2 inch)

waste pipe.

The push fit end must be fully

inserted into the Gully prior to

connecting to the waste pipe.

The Gully and Adapter can then

be solvent welded to the waste

pipe by a fully qualified profes-

sional plumber.

If the waste pipe is not an ABS

plastic 1 1/2 inch or 42,9 mm

pipe then a mechanical fixing

connector must be used to

connect the Gully outlet to the

waste pipe by a fully qualified

professional plumber.

Once the gully has been con-

nected to the waste pipe and

tested for leaks by your fully

qualified plumber.

The concrete

installation support

may be nailed or

screwed to the

surface. Ensure your

DPM is not broken.

2

Gör plats för brunnen på önskad

plats med rekommenderade

kottlingar. Förstärk golvbjälkarna

när urtag måste göras.

Brunnen måste placeras

centralt i förhållande till

tänkt placering av ram/sil.

För att få sil/ram symmetriskt

placerad i duschen måste

brunnsdelen monteras längs

duschutrymmets mittlinje.

PLACERING VID VÄGG.

Brunnen kan monteras i direkt

anslutning till vägg, men vi

rekommenderar att brunnen

monteras med ett avstånd på

50 mm från väggen. Detta gör

det möjligt att montera en smal

remsa med golvplattor mellan

vägg och brunn, med fall från

vägg. Därmed minskar man

belastningen på golvets tätskikt.

Brunnen skruvas fast i

träbjälklaget.

Använd handverktyg!

Tryck den tvådelade monterings-

ramen på plats under brunnen.

Kontrollera

att PURUS LINE

monteras i våg!

Brunnsdelen är

400 mm bred.

Bredd på

duschutrymmet

It must be

installed flat

52743_måttskiss

WEIGHT:

Sammanställning

A1

SHEET 1 OF 1

SCALE:1:5

DWG NO.

TITLE:

REVISION

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR:

ANGULAR:

Q.A

MFG

APPV'D

CHK'D

DRAWN

14

PURUS CENTRE LINEAR 800 Wet Room Solution

Concrete

Step 4

Ensure the Tanking Kit is installed as per the Instructions.

Ensure you follow the Tanking Kit instructions and that the tapes and

membranes are fully secure and the concrete floor is primed. The clam-

ping frame is m ounted after the sealing/tanking layer (1).

Position the clamping frame and pierce

holes for the screws with

an awl tool.

Tape/ fabric

membrane

(1)

Gasket

Step 2

Linear wetroom gully is placed

on the surface and the height is

adjusted by PURUS support.

Connect the gully to the waste

pipe. The installation is attached

to the reinforcement with steel

wire.

The concrete

installation

support may

be nailed or

screwed to

the surface.

IMPORTANT:

Leave the protection plastic

on during cementing!

On rough

concrete bed,

the mounting can be fixed with cement

under the gully (fig. B).

(1)

Step 3

The floor is cemented, then primed

and the membrane/tapes (1) is mounted

to the upper part of the channel.

Linear Wetroom 800 gully is installed

on the same level as sealing/tanking

layer.

It must be

installed flat

Gasket

Tape or

fabric membrane

Waste pipes

If your If your waste pipe is an

ABS plastic 1 1/2 inch or 42,9

mm pipe then you can use the

supplied 42.9 mm (1 1/2 inch)

ABS pipe adapter provided for

solvent welding and connecting

to the 42.9 mm (1 1/2 inch)

waste pipe.

The push fit end must be fully

inserted into the Gully prior to

connecting to the waste pipe.

The Gully and Adapter can then

be solvent welded to the waste

pipe by a fully qualified profes-

sional plumber.

If the waste pipe is not an ABS

plastic 1 1/2 inch or 42,9 mm

pipe then a mechanical fixing

connector must be used to

connect the Gully outlet to the

waste pipe by a fully qualified

professional plumber.

Once the gully has been con-

nected to the waste pipe and

tested for leaks by your fully

qualified plumber.

When the concrete

is set, the gully is

placed in the hole

and connected to the

drain pipe. Fill the

hole with concrete.

Cut in portion. When the

drain pipe is moulded, make

a cut in portion in the mould

form, which is approximately

5cm longer and wider than

gully.

02831

The Purusline Living gully is placed on the

surface and the height is adjusted by the

concrete support.

Ensure your DPM below the concrete is not

broken.

Connect the gully to the waste pipe. The

installation is attached to the reinforcement

with steel wire.

Waste pipes

If your waste pipe is an ABS plastic 1½

inch or 42.9mm pipe then you can use

the supplied 42.9mm (1½ inch) ABS pipe

adapter provided for solvent welding and

connecting to the 42.9mm (1½ inch) waste

pipe.

The push fit end must be fully inserted into

the gully prior to connecting to the waste

pipe. The gully adapter can then be solvent

welded to the waste pipe by a fully qualified

professional plumber.

If the waste pipe is not an ABS plastic 1½

inch or 42.9mm pipe then a mechanical

fixing connector must be used to connect

the gully outlet to the waste pipe by a fully

qualified professional plumber. Once the

gully has been connected to the waste pipe

and tested for leaks by your fully qualified

plumber, you can pour the concrete.

The showering area should have falls built

into the subfloor so that the water runs

towards the drain. The minimum for this

should be 1:150 to ensure the flow of water

to the floor trap and no more than 1:50 to

reduce the risk of slipping. A nominal 2%

falls is usually used.

If you have existing walls covered with

plaster or plasterboard use Puragum Primer

to seal the walls. If the walls are not covered,

then clad walls with panels or plaster board

(not supplied) and coat with Puragum

Primer (follow the instructions provided in

the tanking kit). Once the floor is cemented,

then prime and allow to cure with Puragum

Primer from the tanking kit.

Then totally fill the following gaps with the

MS Polymer, smoothing down as you go

along and ensuring that all the gaps are fully

sealed:

1). between the gully and the concrete;

2). between the walls and the floor.

Then allow a minimum of one hour for the

MS Polymer to tack over before applying the

tapes and gasket.