Quick reference card for flex draper headers – MacDon 974 Quick Card User Manual

Page 4

Quick Reference Card for Flex Draper Headers

Form 147351

Rev. C (E26972)

Page 4 of 4

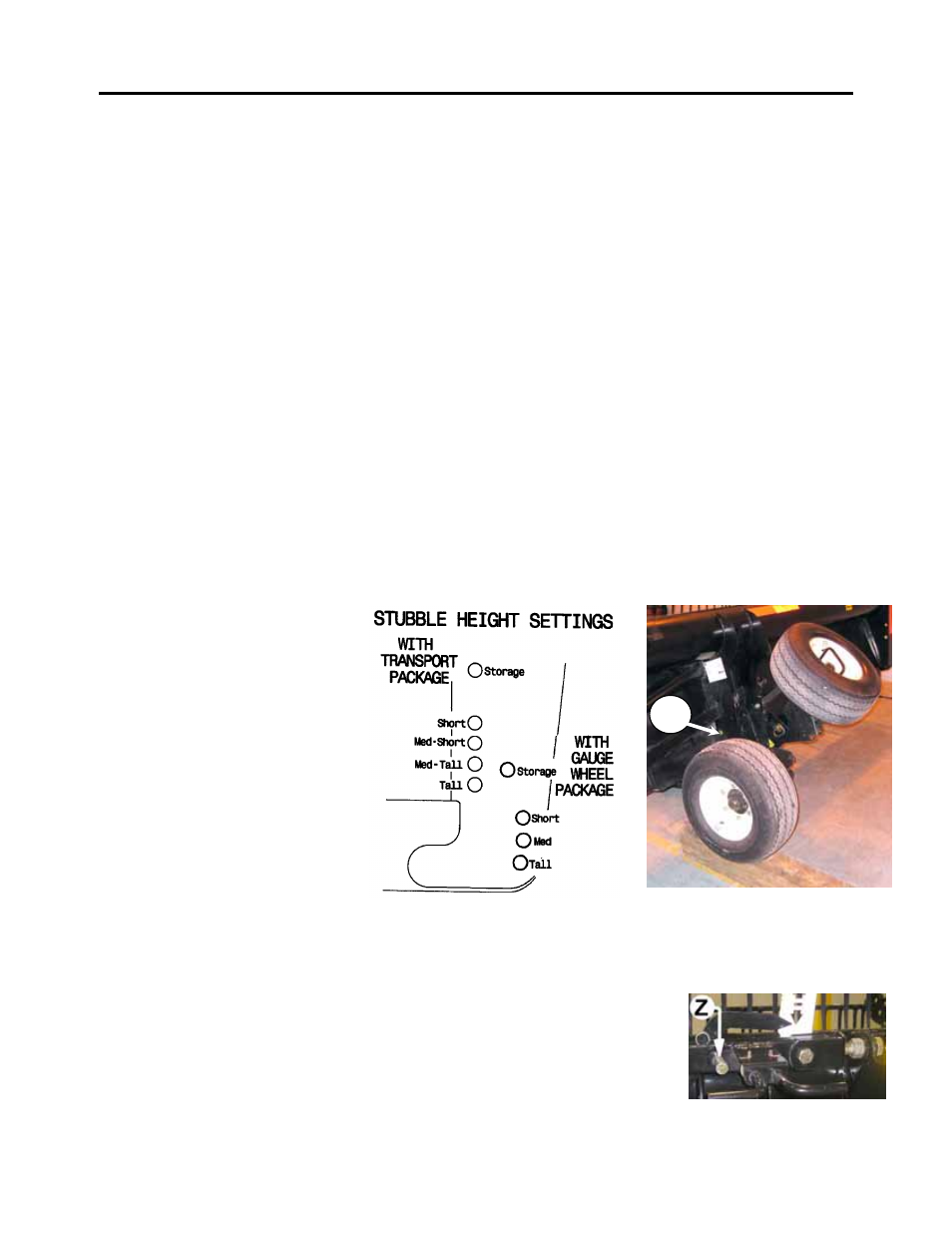

Fig. 11 Transport/ Gauge Wheel Storage Positioning

S

8. Operator Controlled Adjustments

• Float Optimizer (Combine Auto Header Height) - Controls down force on cutter bar with automatic height control.

o Lower ground pressure or flatter angle is required if there is excessive pushing of trash and dirt.

o More ground pressure is required if cutter bar rides up on stubble or does not follow ground.

o A good starting point for ground pressure is one number above nominal (See Step 5) on FO indicator

.

ie. If FO

gauge reads 2 when cutter bar is just above the ground the float optimizer should read 3 when on the ground.

o The bigger the number on optimizer gauge= more ground pressure, less floatation.

o The smaller the number on optimizer gauge= less ground pressure, more floatation.

• Hydraulic Guard Angle - Control stubble height by adjusting the center link length to set guard angle.

o Steeper guard angle is required if stubble is too high across full width of header.

o Reduce guard angle to raise guard point to ride over rocks and ground trash

• Skid Shoe Height Adjustment:

o Use skid shoes along with the hydraulic guard angle adjustment to vary cutting height.

o Lowering the skid shoes raises the cutting height. This may be desirable in stony conditions, to reduce damage

to cutting components. Other benefits include reduced cutterbar pushing or uneven cutting height, due to mud

or dirt buildup.

o Refer to 974 Operator’s Manual for further skid shoe adjustment details.

• When you are cutting on the ground gauge/transport wheels are recommended to be run in storage position.

9. Locking Gauge Wheels/Transport

Wheels up into Storage Position

(For on the ground cutting

applications)

• Lock wings and engage float lock-out.

• Raise header high enough to insert 8”

[200mm] blocks under wheels. Lower

cutterbar to the ground and retract table

angle cylinder fully. Install pin (S) into

storage position.

Note:

If always cutting on the

ground it is recommended to

remove springs from

gauge/transport wheels. By

removing springs, blocking of the

wheels would not be necessary.

Springs could be added back in for

higher cutting heights if necessary.

10.

For Maximum Stability and Adapter Clearance When Transporting with Gauge

Wheel/ Transport Option.

(Refer to Slow Speed Transport Manual Form # 46581 for complete details).

• Remember to insert Pin Z. (Installed with cutterbar in full frown).