Quick reference card for flex draper headers, 2m 1 p – MacDon 974 Quick Card User Manual

Page 3

Quick Reference Card for Flex Draper Headers

Form 147351

Rev. C (E26972)

Page 3 of 4

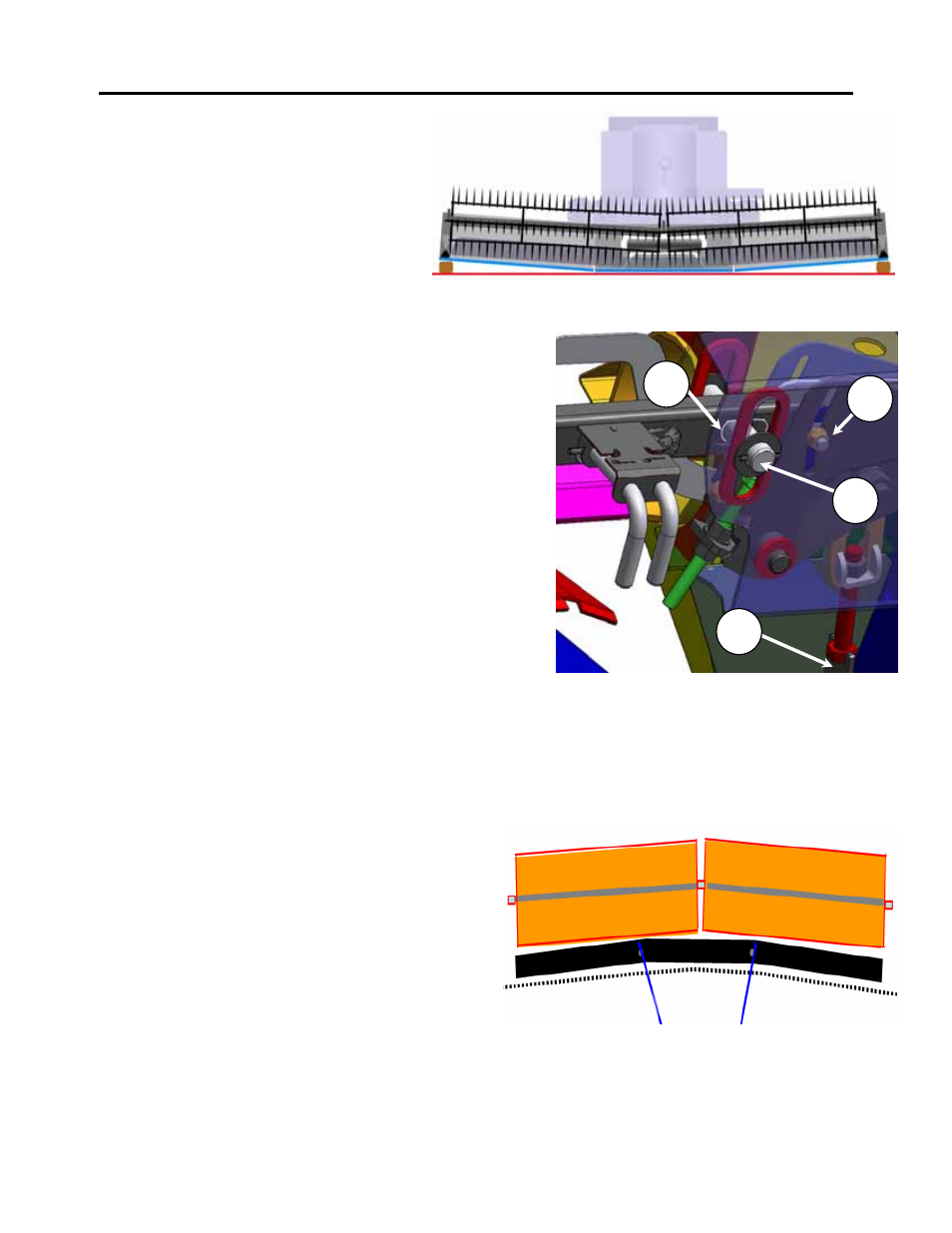

Fig. 10 Hinge Points Reel Clearance

Fig 9. Wing Flex Range- Frown Shown

Smile to be Checked at Other End of the Slot

2

M

1

P

Fig. 8B Block Test – Header Smile

(Block Test) Header Smile

a. Lower header to ground and engage wing lock

pins.

b. Raise header and place 150mm (6”) blocks

under the cutter bar, at crop dividers.

c. Lower header until it touches blocks and remove

wing lock pins.

d. Cutter bar should begin going into smile before

float optimizer gauge has moved one full

number.

e. Full smile should occur before gauge has

moved two full numbers.

Block Test Analysis (Refer to Tech Manual for more in

depth analysis)

a. If less ground pressure was required to frown the wing than to

smile the wing, there is too much weight on the wing. Refer back

to step 4. Check Frown Adjustment and make wing lighter.

b. If less ground pressure was required to smile the wing than frown

the wing, the wing is too light. Refer back to step 4. Checking

smile adjustment and add weight to the wing.

6

. Wing Flex Range

• Frown Flex Range needs to be checked with header in frown

position.(see Fig.8A) Pin (1) must reach end of travel slot (2)

(range 0-3mm (1/8”) gap).

• Smile Flex Range needs to be checked with the header in smile

position. Pin (1) must reach end of travel slot (2) (range 0-3mm

(0-1/8”) gap).

NOTE: Wings should reach full flex range within the same

amount of movement on the float optimizer.

**NOTE: If full frown or smile range is not achieved the vertical strut needs to be adjusted. To achieve full frown or

smile consult the Technical Manual. This is a factory adjustment and should normally not need adjusting.

• Repeat block test to check wing flex if strut has been adjusted.

7.

Reel Adjustments

• Move reel fore-aft to mid position #5 or 6 on gauge.

• Place header into full frown position.

• Reel to guard clearance at hinge points: 7mm [1/4”] tip to

hinge points.

NOTE: Reel clearances are factory set, and no adjustment

should be required.

**NOTE: This adjustment is critical when beans are short or thin. This adjustment must be made in full frown

position with a fair bit of down pressure from combine feeder housing.