Utl series, Technical information, Underwriter laboratories – Northern Connectors Souriau UTL Series Push-Pull Connectors User Manual

Page 42

42

© 2012 – SOURIAU

UTL Series

Technical information

There are two main standards for industrial connectors: UL94 & UL1977

UL 94: Tests for Flammability of Plastic Materials for Parts

in Devices and Appliances

This standard is dedicated to plastics fl ammability. It characterises how the material burns in various orientation and thicknesses. Whereas

most of our competitor are using a 50W test to classifi ed the ability of their solution to withstand fi re, Souriau decided to increase this to a

500W test. New regulations tend to emphasize the importance of burning behavior making the 50W test less and less relevant.

The UTL series has been rated at 5VA.

Procedure: Bar specimens are to be 125

±5

mm long by 13

±0.5

mm wide, and provided in the minimum thickness.

Plaque specimens are to be 150

±5

mm by 150

±5

mm and provided in the minimum thickness.

Thicker specimens may also be provided and shall be tested if the results obtained on the minimum thickness indicate inconsistent test

results. The maximum thickness is not to exceed 13 mm.

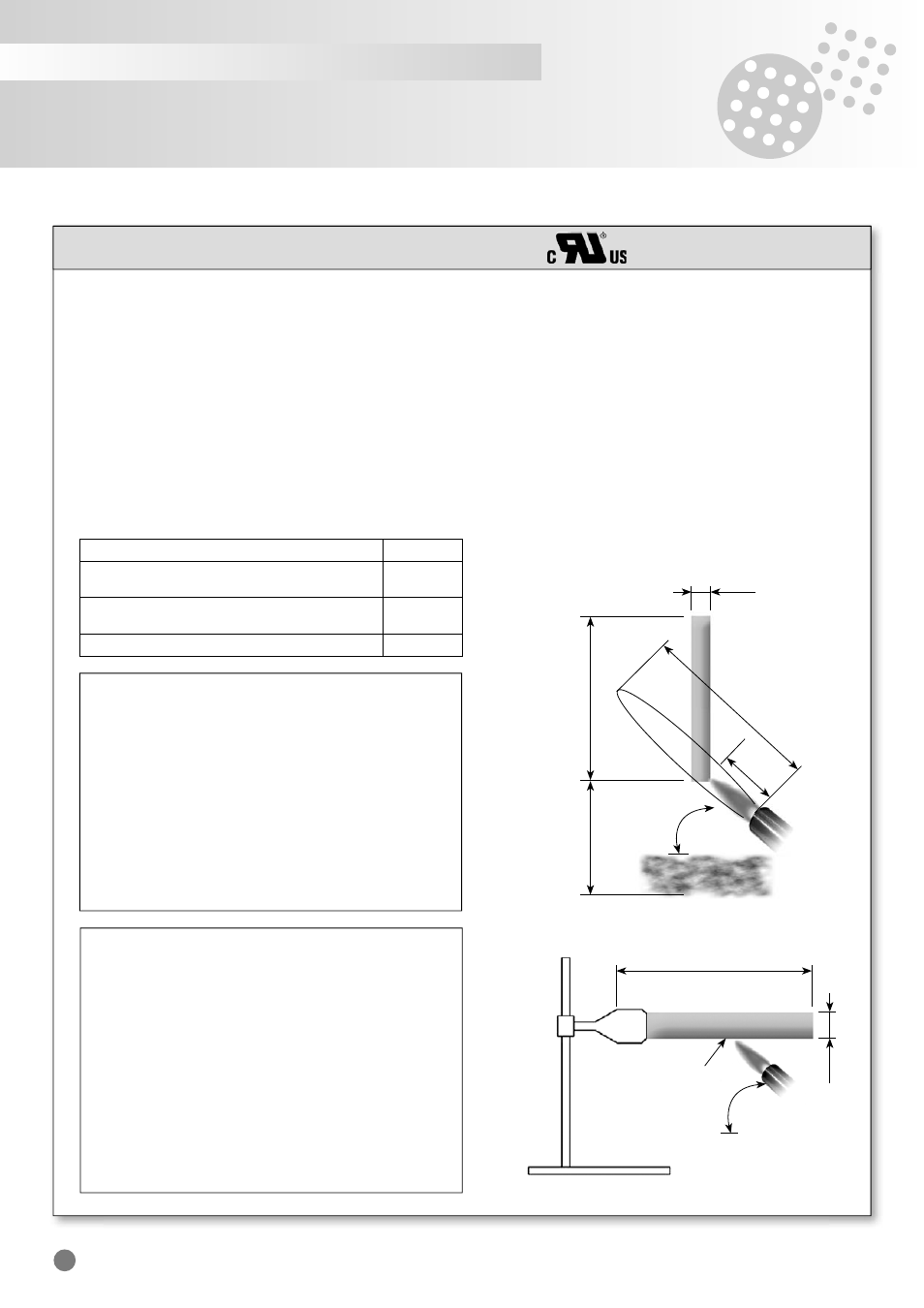

5VA Vertical burning:

• The specimen is clamped from the upper 6 mm of the

specimen, with the longitudinal axis vertical, so that the

lower end of the specimen is 300

±10

mm above a horizontal

layer of not more than 0.08 g of absorbent cotton thinned to

approximately 50 x 50 mm and a maximum thickness of

6 mm.

• The 500W fl ame is then to be applied to one of the lower

corners of the specimen so that the tip of the blue cone is

within 0 to 3 mm of the specimen edge.

• Apply the fl ame for 5

±0.5

seconds and then remove for

5

±0.5

seconds. Repeat the operation until the specimen

has been subjected to fi ve applications of the test fl ame.

Underwriter Laboratories

5VA Horizontal burning:

• Support the plaque specimen by a clamp in the horizontal

plane.

• The fl ame is then to be applied to the centre of the bottom

surface of the plaque so that the tip of the blue cone is within

0 to 3 mm of the plaque surface.

• Apply the fl ame for 5

±0.5

seconds and then remove for

5

±0.5

seconds. Repeat the operation until the plaque specimen

has been subjected to fi ve applications of the test fl ame.

• After the fi fth application of the test fl ame, and after all fl aming

or glowing combustion has ceased, it is to be observed

whether or not the fl ame penetrated (burned through) the

plaque material. In addition, no opening greater than 3 mm

shall appear after the test.

Conditions

94-5VA

Afterfl ame time plus afterglow time after fi fth fl ame

application for each individual bar specimen

60s

Cotton indicator ignited by fl aming particles or drops

from any bar specimen

No

Burn-through (hole) of any plaque specimen

No

300

±10

mm

125

±10

mm

13

±0.5

mm

45°

Cotton

Cotton

Material

Material

Overall height of fl

ame

Inner blue

cone

13

±0.5

mm

Material

Material

150

±0.5

mm

Center

45°