Maintenance, Suspension – Multiquip Trailers User Manual

Page 35

trailer • owner's manual — rev. #4 (11/08/13) — page 35

Replacing Fasteners

Should any of the fasteners become damaged, lost or

corroded, it is important to replace them with fasteners of

the same size and strength grade (or better) as the originals.

Be sure that the fastener components (capscrew, washer

and nut) are all of the same strength grade.

suspension

Leaf Suspension

The leaf suspension springs and associated components

(Figure 16) should be visually inspected every 6,000 miles

for signs of road damage, excessive wear, elongation of

bolt holes, and loosening of fasteners. Replace all damaged

suspension parts immediately. Torqued suspension

components as detailed in Table 6.

Figure 16. Leaf Suspension Components

U-BOLT

LEAF

SUSPENSION

TIE PLATE

AXLE

U-BOLT

LOCKING

NUT

SHACKLE

BOLTS

FRONT

HANGER BOLT

FRONT

HANGER NUT

SHACKLE

NUTS

SHACKLE SUPPORT

BRACKET IS WELDED

TO FRAME

HANGER SUPPORT

BRACKET IS WELDED

TO FRAME

table 6. Fastener types and strength grades

item

torQue (Ft.-lbs)

3/8"" U-bolt

Min-30 Max-35

7/16"" U-bolt

Min-45 Max-60

1/2"" U-bolt

Min-45 Max-60

Equalizer Bolts

Snug fit only. Parts must rotate freely.

Locking nuts are provided to retain nut-

bolt assembly.

Shoulder Type

Shackle Bolt

maintenance

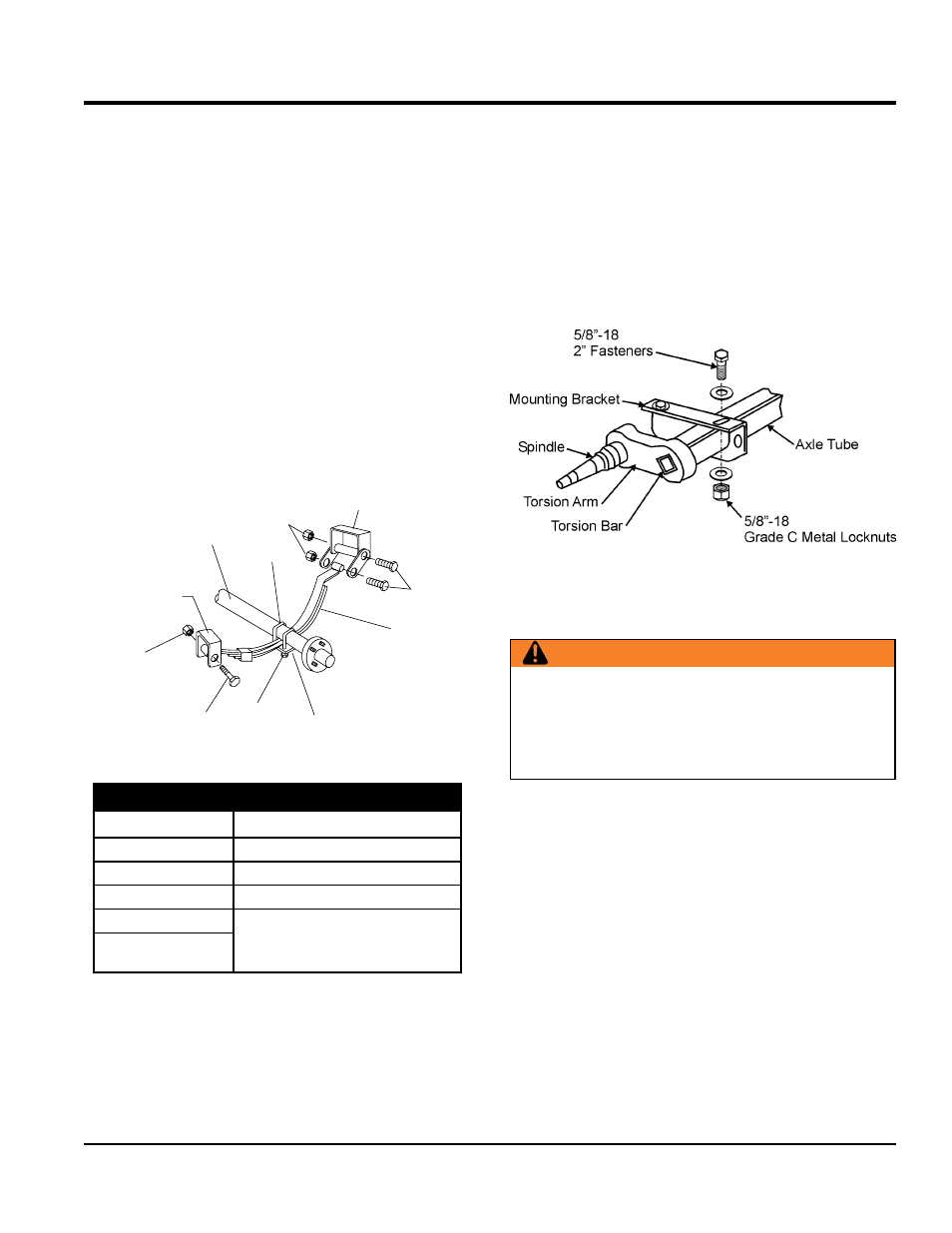

Torsion Suspension

With torsion systems, the suspension takes place inside

the square tube which is filled with highly resilient rubber.

The mounting bracket of the torsion assembly is bolted

directly to the trailer frame. (See Figure 17 below). Except

for periodic inspection of the bracket’s fasteners to the

vehicle frame, no other suspension maintenance is required

on the axles.

Figure 17. Torsion Suspension Components

warning

Worn or broken suspension parts can cause loss of

control and injury may result.

Have trailer professionally inspected annually and after

any impact.