Maintenance, Axle bolts, frame, suspension and structure, Trailer structure – Multiquip Trailers User Manual

Page 34: Welds, Fasteners

page 34 — trailer • owner's manual — rev. #4 (11/08/13)

axle Bolts, Frame, suspension anD

struCture

To perform many of the inspection and maintenance

activities, you must jack up the trailer using jacks and jack

stands. When jacking and using jack stands, place them so

as to clear wiring, brake lines, and suspension parts (i.e.,

springs, torsion bars). Place jacks and jack stands inside

of the perimeter strip on the supporting structure to which

the axles are attached.

trailer structure

Because the trailer receives the most abuse, it will most

likely corrode before any other part of the structure. Using

a power washer and a detergent solution, thoroughly wash

the trailer to remove road grime, bugs, salt or mud. Be sure

to take time to check all electrical connections including

lights and the brakes, if your trailer is equipped with an

electric brake system. Inspect the trailer license plate and

make sure it is clean and legible.

welds

All welds can crack or fail when subjected to heavy loads

or movement of cargo that was not properly tied to prevent

movement. Any time that you know or suspect that the

trailer has been subjected to heavy loads or movement

of cargo, immediately inspect the welds and fasteners for

damage. Broken or damaged welds can cause injury or

severe damage to your trailer and contents. Inspect all of

the welds for cracks or failure at least twice a year.

Fasteners

Various fastener types may be used on your trailer.

warning

Never crawl under your trailer unless it is on firm

and level ground and resting on properly placed and

secured jack stands.

warning

Improper weld repair will lead to early failure of the

trailer structure and can cause serious injury or death.

Do not repair cracked or broken welds unless you have

the skills and equipment to make a proper repair. If not,

have the welds repaired by your dealer.

maintenance

Fasteners provide certain advantages over welded

connections in some cases, however, it is important to

periodically inspect all of the fasteners to insure proper

maintenance of the trailer.

Tightening Loose Fasteners

When tightening loose fasteners, it is important that they be

tightened to their proper torque setting (See Table 5). Under

tightening may cause them to loosen or disengage during

use of the trailer. Over tightening may damage the fasteners

and their components causing them to fail or break.

warning

Damaged, loose or missing fasteners will weaken the

trailers structure and can cause serious injury and

damage to the trailer and contents. Tighten loose

fasteners to their proper torque setting.

NOTICE

never use an pneumatic air gun to tighten fasteners.

Always use a properly calibrated torque wrench.

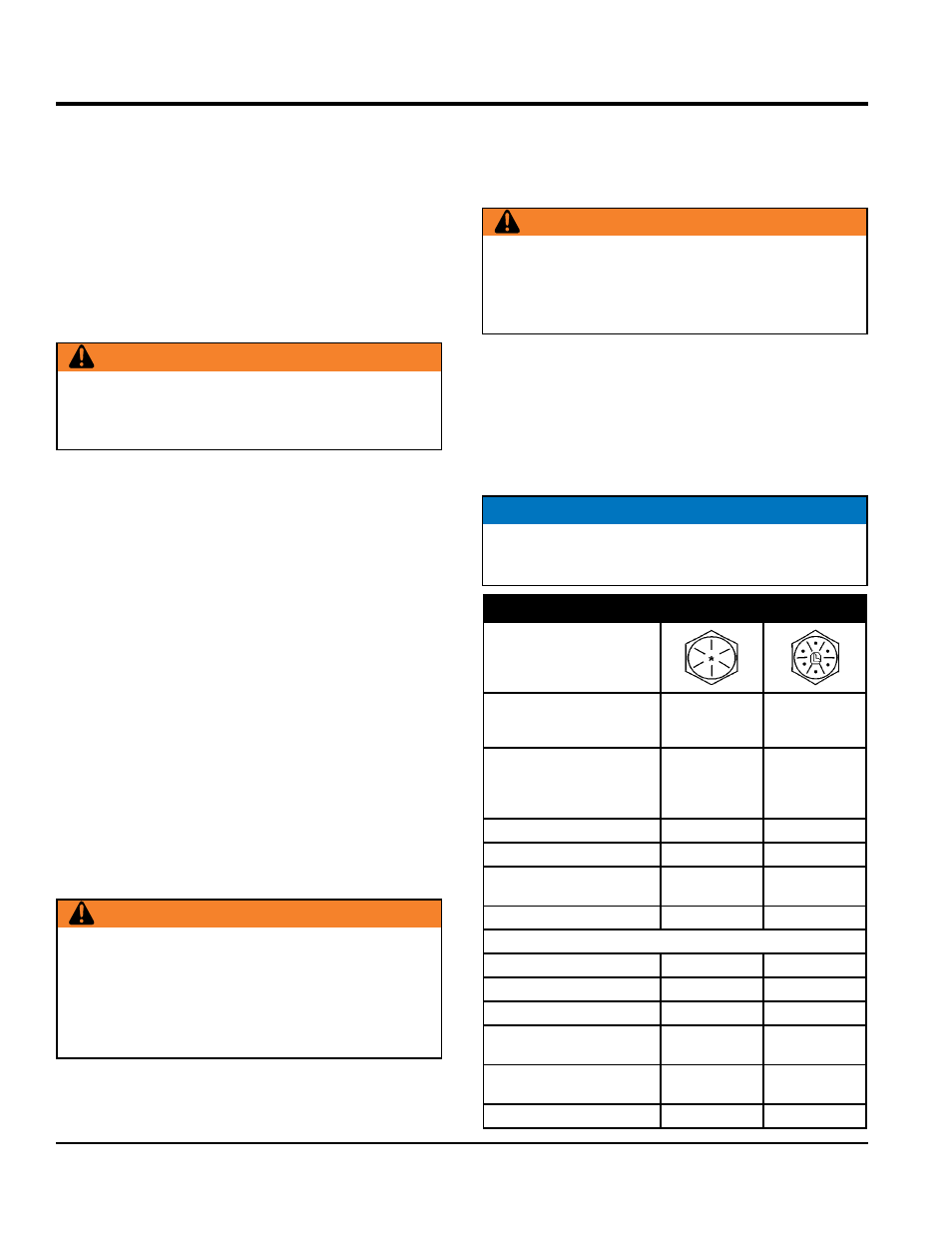

table 5. Fastener types and strength grades

Strength Grade Markings

Definition

6 Radial Lines

SAE Grade 8

ASTM A-354BD

Lawson

TRU-TORQ®

Material

Medium Carbon

Alloy Steel

Quenched

& Tempered

Special Analysis

Alloy Steel

Quenched

& Tempered

Proof Load Strength Psi

120,000 psi min. 150,000 psi min.

Single Shear Strength Psi

97,000 psi

117,000 psi

Ultimate Tensile Strength Psi

150,000 psi min. 180,000 psi min.

190,000 psi avg.

Torque Requirements

130 (ft lbs.)

140 (ft lbs.)

Fastener Size

Coupler

5/8"" - 11

N/A

W/ Nylon Insert Locknut

5/8"" - 11

N/A

Torsion Axle

N/A

5/8"" - 18

W/ Grade C All Metal

Locknut

N/A

5/8"" - 18

Hydraulic Actuator & Electric

Brake Adapter

N/A

5/8"" - 18

W/ Grade C All Metal Locknut

N/A

5/8"" - 18