Mp2 masonry saw — pre-setup (gasoline engine) – Multiquip MP2090HP User Manual

Page 24

PAGE 24 — MQ MP2 MASONRY SAW — OPERATION MANUAL — REV. #2 (03/12/13)

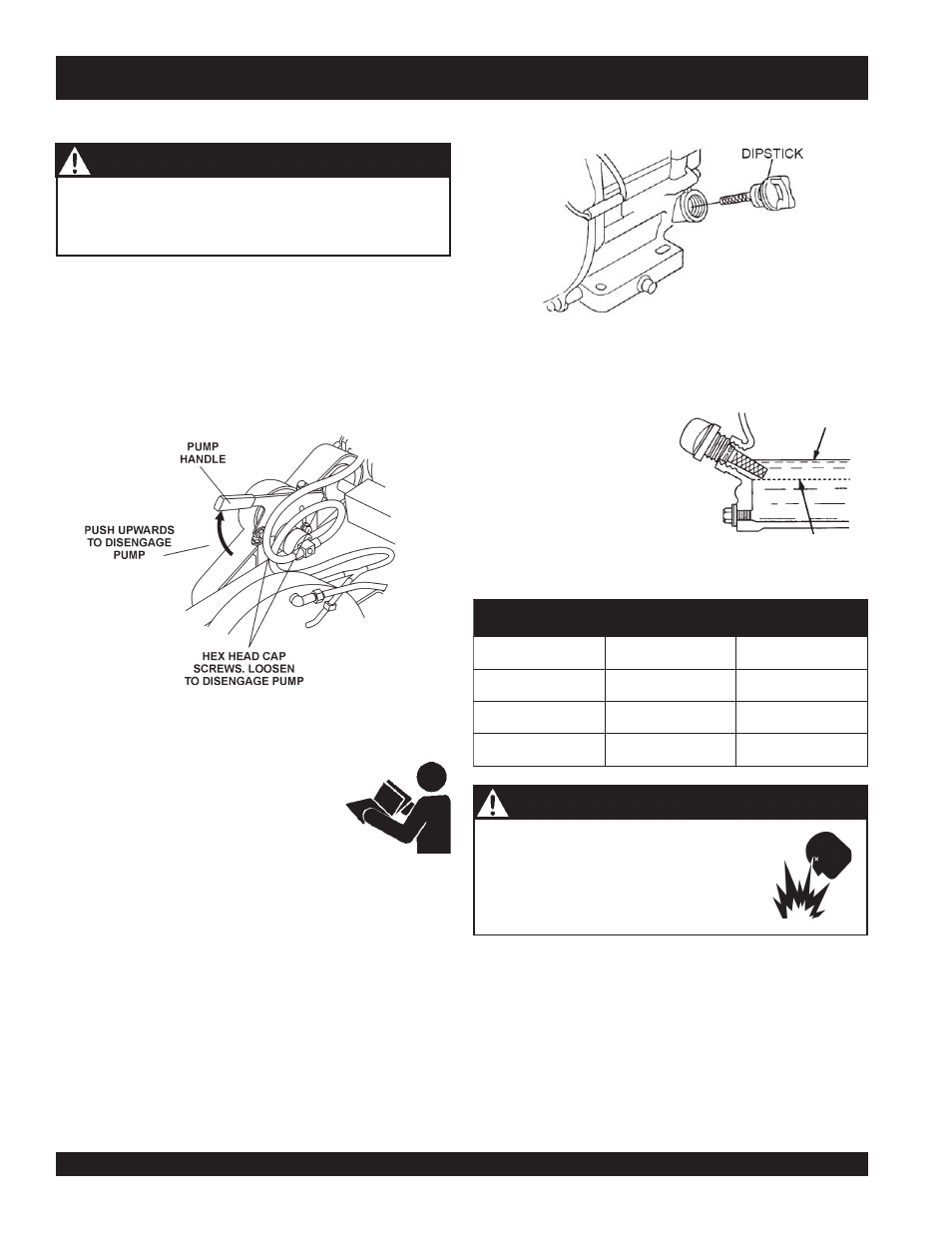

Figure 15. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it into

the filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low

(Figure 16), fill to the edge

of the oil filler hole with the

recommended oil type

(Table 5). Maximum oil

capacity is 1.16 quarts (1.1

liters)

Figure 16. Engine Oil Dipstick (Oil Level)

Before Starting

1.

Read safety instructions at the

beginning of manual.

2.

Clean the saw, removing dirt and

dust, particularly the engine cooling

air inlet, carburetor and air cleaner.

3.

Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one as required.

4.

Check carburetor for external dirt and dust. Clean with

dry compressed air.

5.

Check fastening nuts and bolts for tightness.

Engine Oil Check

1.

To check the engine oil level, place the saw on a secure

level surface with the engine stopped.

2.

Remove the filler dipstick from the engine oil filler hole

(Figure 15) and wipe clean.

Fuel Check

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if the fuel level is low. If fuel is

low, replenish with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO

NOT top-off fuel. Wipe up any spilled fuel

immediately!

DANGER - Explosive Fuel

Motor fuels are highly flammable and

can be dangerous if mishandled. DO

NOT smoke while refueling. DO NOT

attempt to refuel the pump if the engine

is

hot! or running.

E

P

Y

T

L

I

O

.

5

E

L

B

A

T

n

o

s

a

e

S

e

r

u

t

a

r

e

p

m

e

T

e

p

y

T

li

O

r

e

m

m

u

S

r

e

h

g

i

H

r

o

C

°

5

2

0

3

-

W

0

1

E

A

S

ll

a

F

/

g

n

i

r

p

S

C

°

0

1

~

C

°

5

2

0

2

/

0

3

-

W

0

1

E

A

S

r

e

t

n

i

W

r

e

w

o

L

r

o

C

°

0

0

1

-

W

0

1

E

A

S

MP2 MASONRY SAW — PRE-SETUP (GASOLINE ENGINE)

To disconnect the

mechanical water pump from the drive

V-belts for

Dry Cutting, perform the following:

1.

Loosen the 2 hex head cap screws (Figure 14) that

secure the pump mount bracket.

2.

Pull the pump handle upward to disengage the pump.

3.

Tighten the 2 hex head cap screws that secure the

pump mount bracket.

Figure 14. Pump Disengage

ALWAYS use the

water feed system unless special

dry cut blades are being used. If dry cutting is required

disconnect water pump.

Dry Cutting Setup (Gasoline Only)

CAUTION - Dry Cutting

CAUTION - Explosive Fuel

UPPER

LOWER