Sth-55jd-tc — maintenance – Multiquip STH User Manual

Page 18

PAGE 18 — STH-10 FT. • RIDE-ON POWER TROWEL — PARTS & OPERATION MANUAL — REV. #5 (06/08/05)

STH-55JD-TC — MAINTENANCE

Sometimes it may be necessary to match blade pitch between

the two sets of blades. There are some signs that this may be

necessary. For example, the differences in pitch could cause a

noticeable difference in finish quality between the two sets of

blades. Or, the difference in blade pitch could make the

machine difficult to control. This is due to the surface area in

contact with the concrete (the blade set with the greater contact

area tends to stick to the concrete more).

Twin Pitch

Trowel blade pitch is controlled by rocker switches located on

the top of the left and right joystick handles. The rocker switch on

the left handle pitches only the left side blades. The rocker switch

on the right handle pitches blades on both the left and right

sides.

The left side rocker switch is used to "match" blade pitch of the

left and right sides. Once the two sides are "matched" (all blades

on both sides are completely flat), the right side rocker switch

may be used to pitch both sides simultaneously (Twin Pitch).

Important: just as with mechanical Twin Pitch, when using the

right side switch, if the blades on either side reach the maximum

or minimum pitch condition, both sides will

stop

pitching.

If the pitch angle is significantly different between the left and

right side blades, they must be "matched" (blades), using the left

side rocker switch. Always remember to use the left side rocker

switch first when matching the left and right blades. After both left

and right side blades have been matched then the right side

rocker switch (Twin Pitch) can be used.

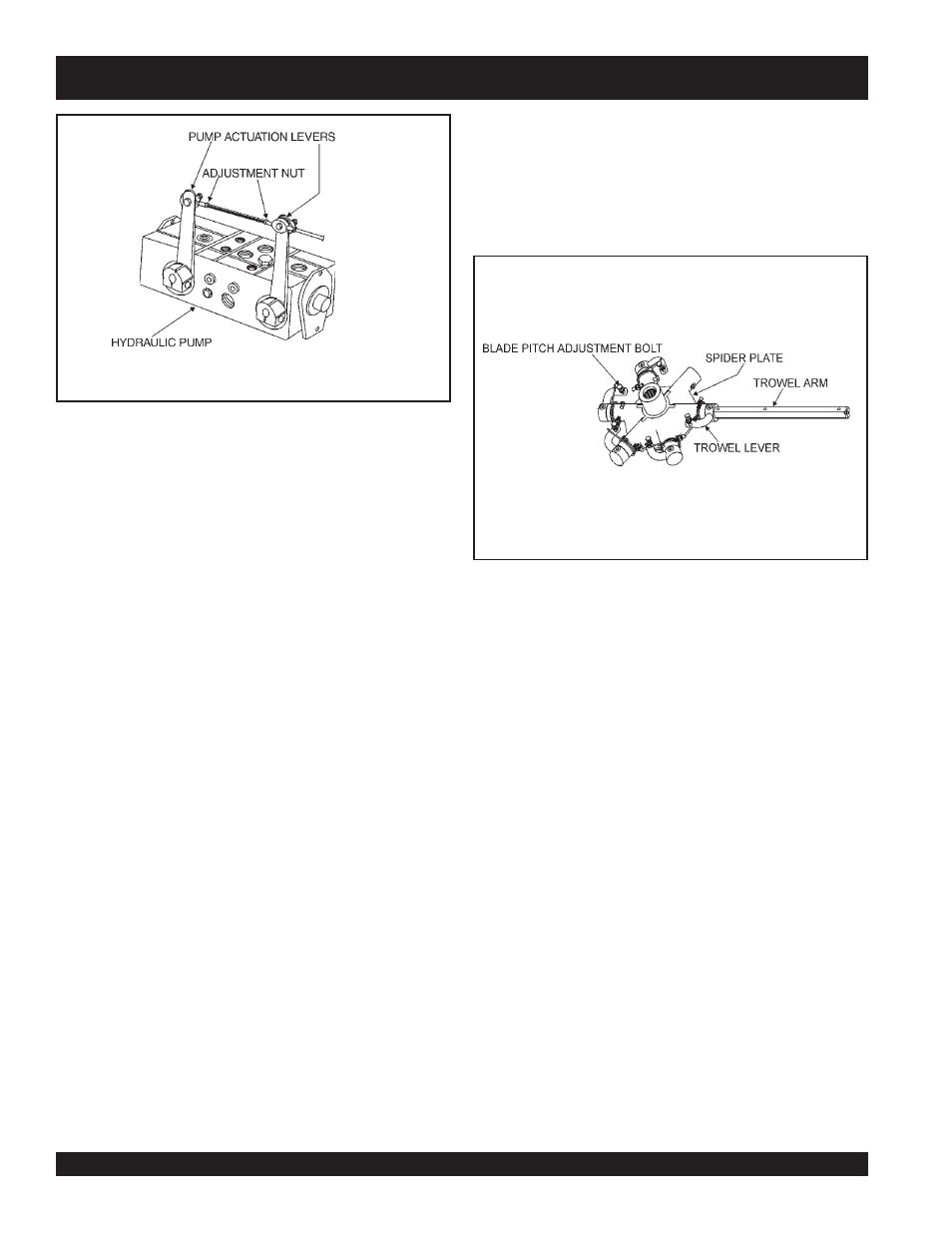

Figure 16. Pump Actuation

Levers/Speed Control Rod

Blade Pitch Adjustment Procedure

The maintenance adjustment of blade pitch is an adjustment

that is made by a bolt (Figure 17) on the arm of the trowel blade

finger. This bolt is the contact point of the trowel arm to the lower

wear plate on the thrust collar. The goal of adjustment is to promote

consistent blade pitch and finishing quality.

There are some things to look for when checking to see if

adjustment is necessary. Is the machine wearing out blades

unevenly (i.e. one blade is completely worn out while the others

look new)? Does the machine have a perceptible rolling or

bouncing motion when in use? Look at the machine while it is

running, do the guard rings “rock up and down” relative to the

ground? Do the pitch control cylinders rock back and forth? These

are some of the indications that the blade pitch may need to be

adjusted using the adjustment bolts on the trowel blade finger.

The easiest and most consistent way to make this adjustment is

to use the Trowel Arm Adjustment Fixture (P.N. 9177) . This fixture

will allow consistent adjustment of the trowel arm fingers. It comes

with all the hardware necessary to properly accomplish this

maintenance and instructions on how to properly utilize this tool.

Adjusting the trowel arm fingers without a fixture requires a special

talent.

If a trowel arm adjustment fixture is not available and immediate

adjustment is necessary; we suggest the following procedure.

If you can see or feel which blade is pulling harder, adjust the

bolt that corresponds to that blade. Another way to determine

which blades need adjustment is to place the machine on a

flat surface and pitch the blades as flat as possible. Now, look at

the adjustment bolts. They should all barely make contact with

the lower wear plate on the spider. If you can see that one of

them is not making contact; some adjustment will be necessary.

Figure 17. Blade Pitch Adjustment Bolt