Sth-55jd-tc — maintenance, Caution – Multiquip STH User Manual

Page 17

STH-10 FT. • RIDE-ON POWER TROWEL — PARTS & OPERATION MANUAL — REV. #5 (06/08/05) — PAGE 17

NOTE

See the engine manual supplied with your machine for

appropriate engine maintenance schedule and troubleshooting

guide for problems.

At the front of the book (Page B) there is a “Daily Pre-Operation

Checklist”. Make copies of this checklist and use it on a daily

basis.

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

Disconnect spark plug wires and battery cables before

attempting any service or maintenance on the ride-on trowel.

MAINTENANCE SCHEDULE

Daily (8-10 Hours)

1.

Check the fluid levels in the engine and reservoir, fill as

necessary.

Weekly (30-40 Hours)

1.

Relube arms, thrust collar and clutch

2.

Replace blades if necessary.

3.

Check and clean or replace the engine air filter as

necessary.

4.

Replace engine oil and filter as necessary, see engine

manual.

Monthly (100-125 Hours)

1.

Remove, clean, reinstall and relube the arms and thrust

collar. Adjust the blade arms.

Yearly (500-600 Hours)

1.

Check and replace if necessary the arm bushings, and

thrust collar bushings.

2.

Check pitch control cables for wear.

3.

Adjust blade speed.

4.

Replace hydraulic fluid and hydraulic filters.

NOTE

After the first 200 hours,

replace the hydraulic

filter cartridges

.

MAINTENANCE PROCEDURES

Checking/Adjusting Blade Speed

Because the two hydraulic drive motors operate independent of

each other, the blade speed between them may vary. If the unit’s

steering is difficult to control, the blade speeds may need to be

checked, or if one spider is spinning noticeably faster or slower

than the other, the blade speed may need to be checked. It is

also recommended that the blade speed be checked at least

once a year.

Blade speed adjustment is a two-step process. First, the left

spider’s speed should be checked and/or adjusted. Second,

the right spider’s speed should be adjusted to match the left.

Left Spider Speed Adjustment

The left spider’s speed is adjusted by changing the length of

the rod end spacing (Figure 15) at the front of the foot pedal.

Lengthening the spacing increases the blade speed; shortening

the spacing decreases the blade speed.

STH-55JD-TC — MAINTENANCE

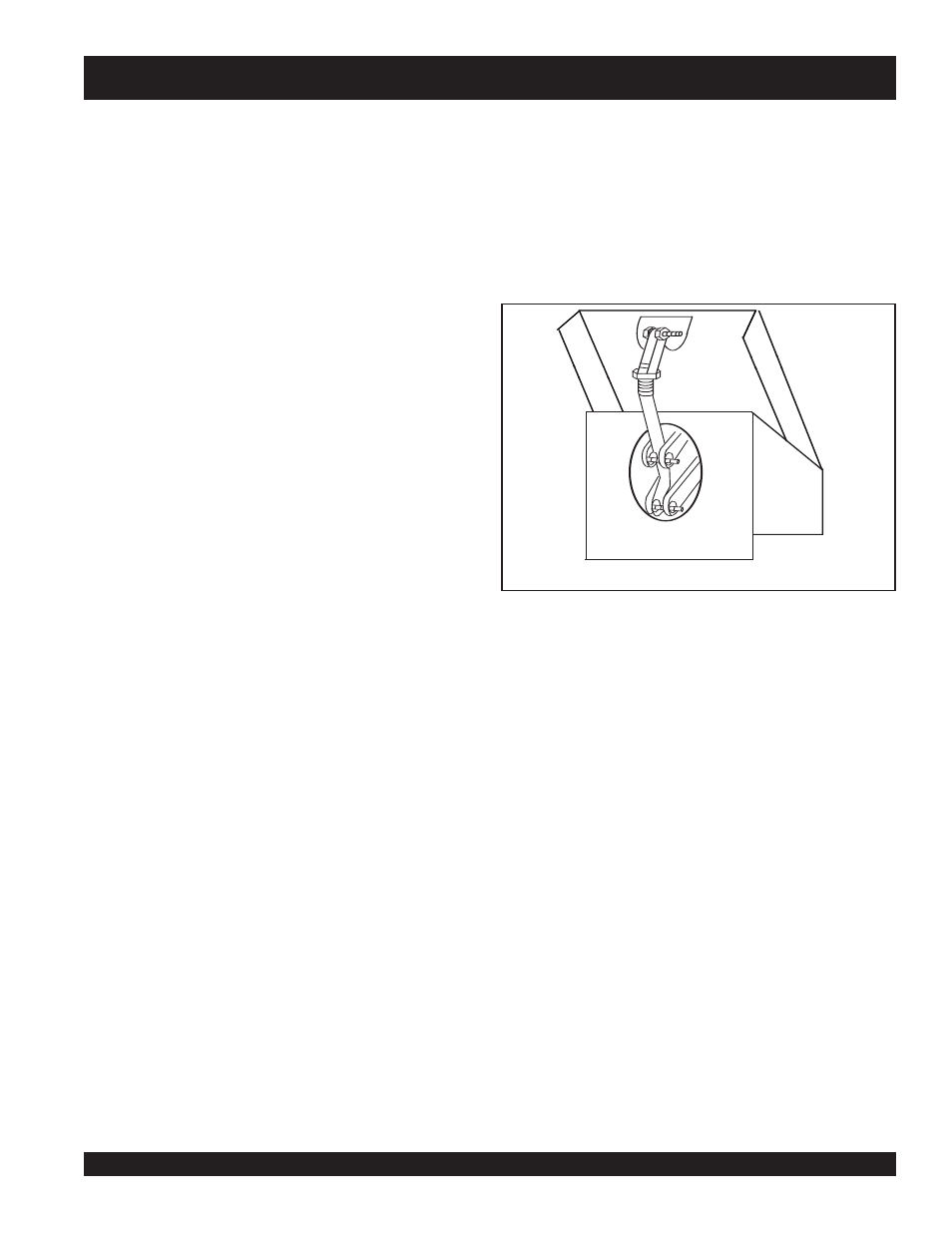

Right Spider Speed Adjustment

The right spider’s speed is adjusted by changing the length of

the connecting rod on the pump actuation levers (Figure 16,

Page 17). This rod is basically a turnbuckle. Rotating it in one

direction increases the length and corresponding spider speed.

Rotating it the opposite direction decreases the length and

spider speed. The right spider’s speed should be within 3 rpm

of the left.

A good starting point in the adjustment process is to adjust the

rod such that both spiders begin to rotate at the same time

when the foot pedal is slowly depressed. This will, generally,

get the speeds close enough for use if instrumentation is

unavailable (i.e. on the job site). From this point on, some form of

instrumentation is required to verify that the right spider speed is

within the tolerance specified above. A strobe or magnetic pickup

type speed indicator is recommended to verify the speeds.

The speeds should be adjusted on a dry concrete floor with the

blades pitched flat. The blade speed should be set at 125-130

rpm with the engine at full speed.

Matching Blade Pitch for Both Sets of Blades

Figure 15. Blade Speed Control Foot Pedal