Maintenance, Clean-up, Trowel arm adjustment procedure – Multiquip JWN24HSCSL User Manual

Page 31

JWN-SeRIeS RIDe-ON pOWeR TROWeL • OpeRaTION maNuaL — Rev. #1 (05/12/12) — page 31

Maintenance

Clean-up

Never allow concrete to harden on the power trowel.

Immediately after use wash any concrete off the trowel

with water, be careful not to spray a hot engine or muffler.

An old paint brush or broom may help loosen any concrete

that has started to harden.

Trowel arm adjustment procedure

A level, clean area to test the trowel prior to and after

adjustment is essential. Any unlevel spots in the floor

or debris under the trowel blades will give an incorrect

perception of adjustment. Ideally, a 5' x 5' three-quarter

inch thick flat steel plate should be used for testing.

1. To determine which blades need adjustment, place the

trowel in the test area (three-quarter inch thick plate)

and look for the following conditions:

• Pitch the blades as flat as possible and look at the

adjustment bolts. They should all barely make contact

with the lower wear plate on the spider. If you can

see that one of them is not making contact, some

adjustment will be necessary.

• Is the machine wearing out blades unevenly (i.e. one

blade is completely worn out while the others look

new)?

NOTICE

The following procedure should be followed to adjust

trowel arms when it becomes apparent that the trowel

is finishing poorly or in need of routine maintenance.

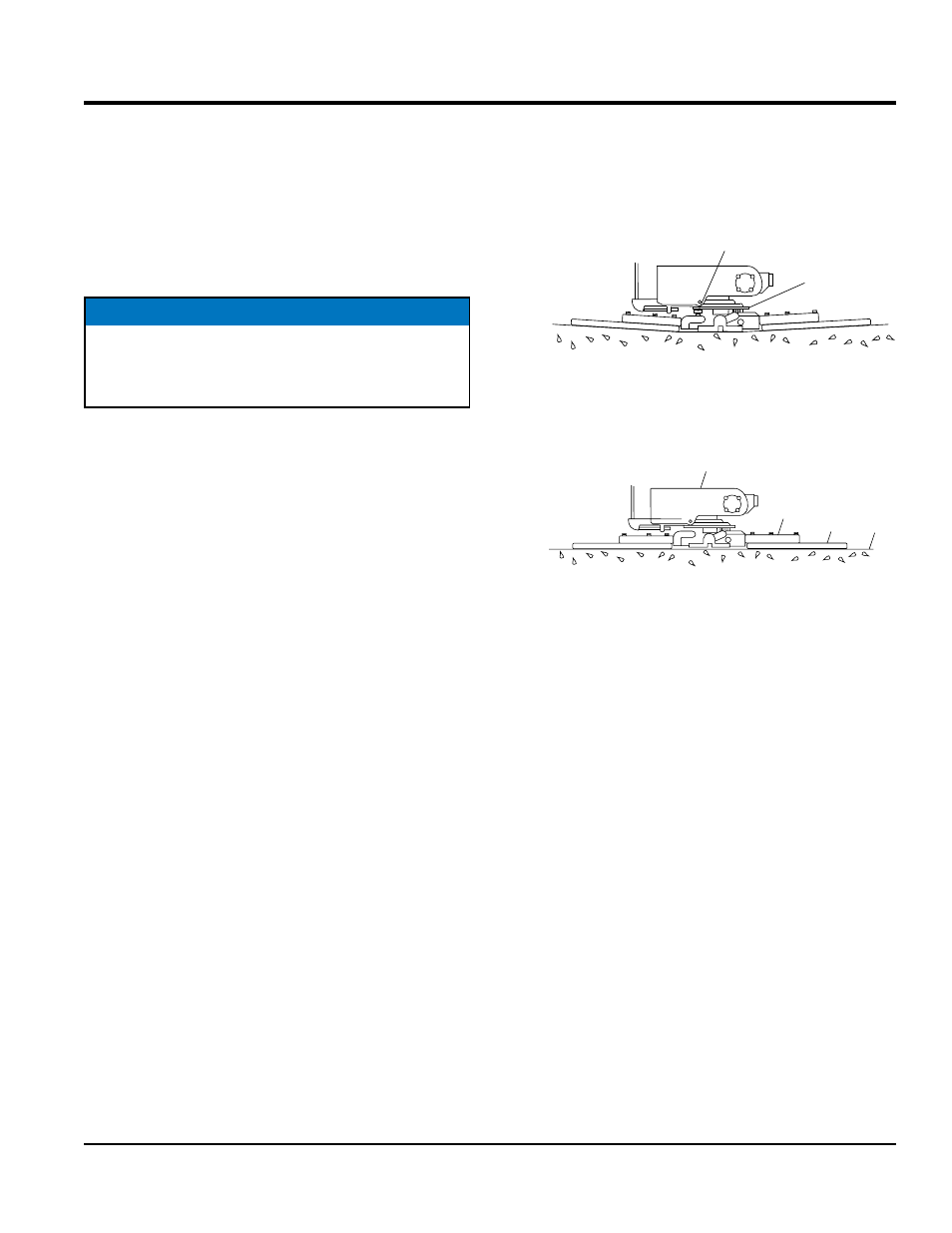

Figure 26 illustrates "worn spider bushings or bent trowel

arms". Check to see that adjustment bolt is barely touching

(0.10" max. clearance) lower wear plate. All alignment bolts

should be spaced the same distance from the lower wear

plate.

Figure 26. Worn Arm Bushings

Figure 27 illustrates the "correct alignment " for a spider

plate (as shipped from the factory).

Figure 27. Correct Spider Plate Alignment

2. Start engine, and bring trowel blades up to full speed

and look for the following conditions:

• Does the trowel have a perceived rolling or bouncing

motion?

• Does the guard ring “rock up and down” relative to

the ground?

SURFACE

LOWER

WEAR

PLATE

“DISHED” EFFECT ON

FINISHED CONCRETE

ADJUSTMENT

BOLT

INCORRECT

ALIGNMENT

ARM

GEARBOX

SURFACE

BLADE

MOUNTING

BAR

CORRECT ALIGNMENT

BLADES ARE FLAT