Mk-101 type blade alignment procedure, Horizontal rough alignment – MK Diamond MK-101 Blade Alignment User Manual

Page 2

MK-101 Type Blade Alignment

Revision 12/00, Effective Date: December 04, 2000

Page-2

MK-101 TYPE BLADE ALIGNMENT PROCEDURE

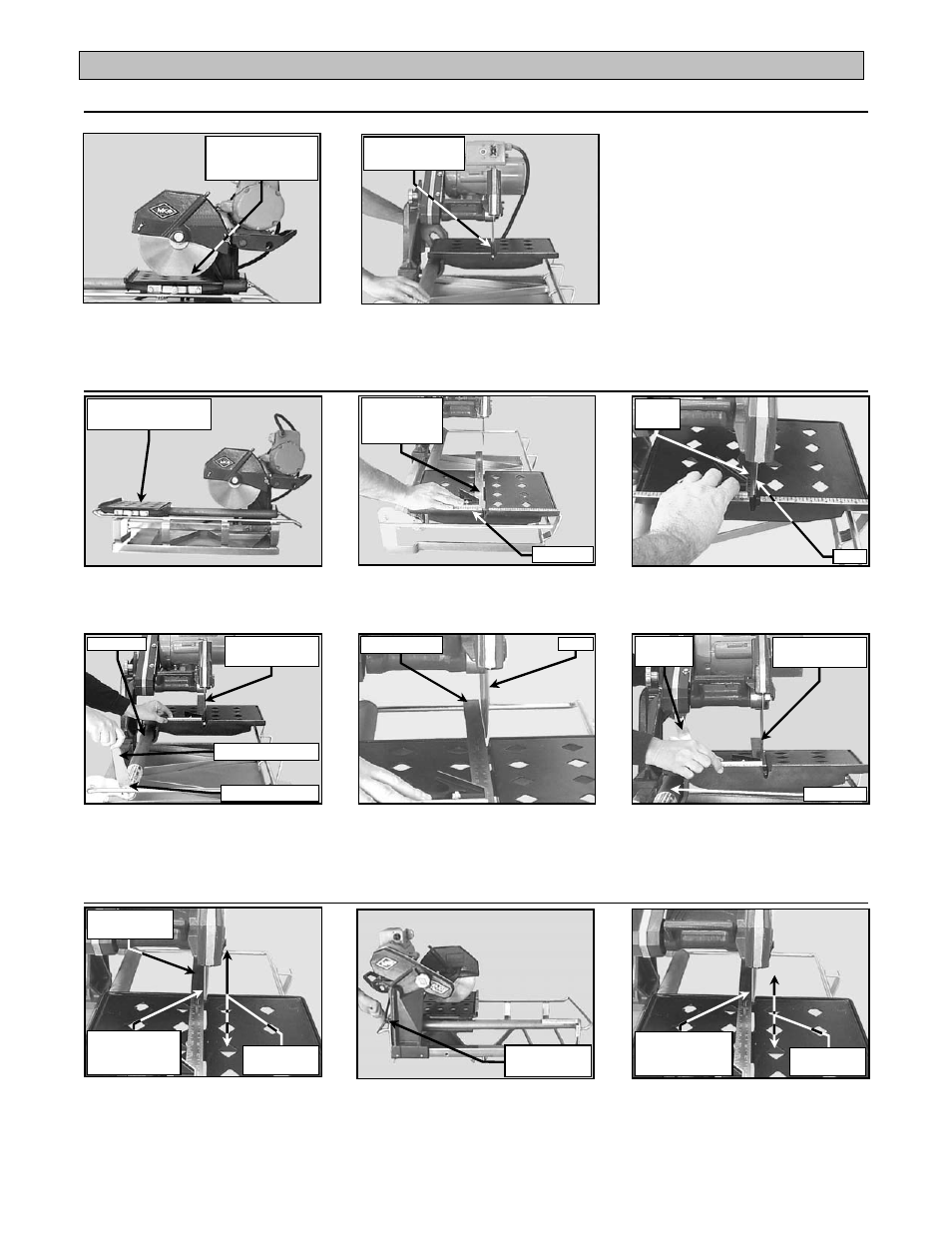

Horizontal Rough Alignment:

The Horizontal alignment will ensure that straight cuts (or Rip Cuts) are made.

Horizontal Final Alignment:

Horizontal Alignment Verification:

(D)

Move Guide Bar using Adjusting

Bracket until Square rests

evenly across Blade

End of Square

Flush with Blade

(A)

Pull Movable Cutting Table

to front of Tile Saw

(B)

Position Square flat on Movable

Cutting Table against Ruler/Stop

(F)

Move Guide Bar using Adjusting

Bracket until Square rests

evenly across Blade

(C)

Position front of Square

against Blade

(B)

Move Guide Bar until Blade is

centered in Cutting Groove

(A)

Move the Cutting Table back and

forth to verify Blade is even

across all points of Square

(B)

Tighten Guide Bar

Retaining Bolts

(A)

Position Cutting Head

to normal Cut Depth

Position Movable

Cutting Table to Front

Ruler/Stop

Place Square

Against

Ruler/Stop

End of Square

Flush with Blade

Front of

Square

Blade

Verify Gap Even

Along Length

of Square

Move Cutting

Table

Turn Clockwise

to Tighten

Re-verify Gap

Even Along

Length of Square

(E)

Position end of Square

against Blade

End of Square

Blade

Guide Bar

Open End

Wrench

Adjusting Bracket

Open End

Wrench

Guide Bar

Move Cutting

Table

Adjust Cutting

Head to Cut Depth

of Approx _”

Center Blade

In Cutting Groove

Set Square Off

Blade

(C)

Move the Cutting Table back and

forth to re-verify Blade is even

across all points of Square