MK Diamond MK-6000 Series User Manual

Page 29

29

Due to the dusty conditions created by sawing, it is essential to check the engine air cleaner element

daily. Remove the element and shake out the accumulated dust and dirt. Wipe out dirt from the inside

cover and from the housing. Check the engine manual for washing instructions. Stocking replacement

filters is strongly recommended.

The operation and life of the engine depends on proper maintenance. Do not start engine until en-

gine pre-check is complete. The engine pre-check consists of checking the oil, fuel level, air filter and

greasing the wheel, axle, drive unit and arbor bearings. Basic engine maintenance is shown in Main-

tenance Schedule Table on the next page. For more detailed information, please refer to the Engine

Operator Maintenance Manual and Warranty provided with the saw.

MK-6000 SaW

MaintenanCe

notiCe

When breaking-in a new saw, we recommend running the engine for one hour with no load prior to

actual use on the job.

enGine

expansion tank and Cap

air CLeaner

ARBOR, AXLE, DRIVE UNIT AND WHEEL BEARINGS

Blades shaft, Axle, Drive Unit, and Wheel Bearings should be greased according to the Maintenance

Schedule table on the next page.

Use of high quality detergent oil of API (American Petroleum Institute) service class SF or SG. Select

the viscosity based on the air temperature at the time of operation. For temperatures below 0ºF, 5W-

20 or 5W-30 oil is recommended. For temperatures above 0º, 10W-30 oe 10W-40 oil is recommend-

ed. Check your engine manual for other recommendations.

WarninG

Do not inspect when the engine is running.

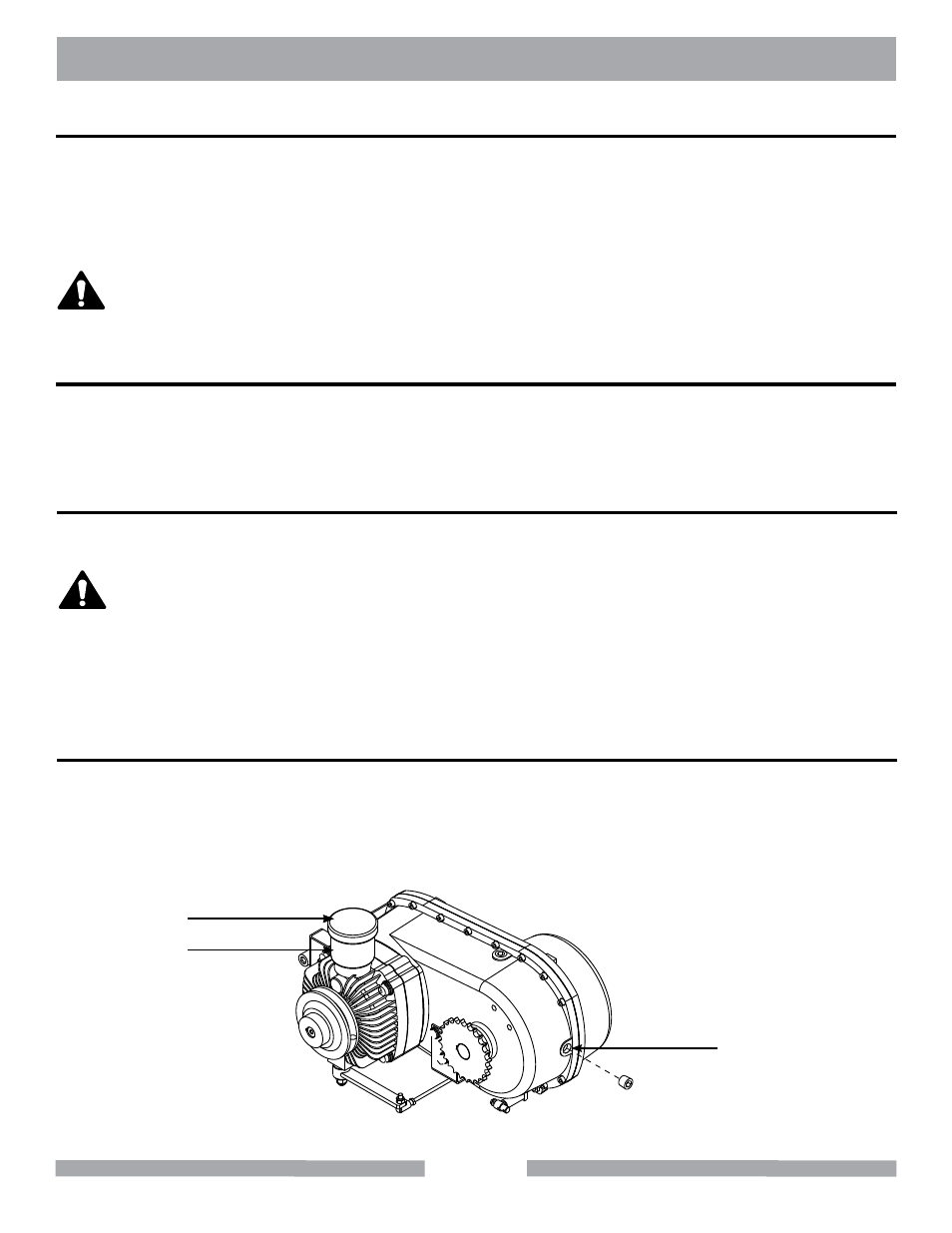

HYDROSTATIC DRIVE UNIT & TRANSMISSION GEARBOX

The fluid shipped in your hydrostatic transmission is a fluid having a viscosity equivalent to SAE

20W20. Mobil fluid 300 or any other oil equivalent to SAE 20W20 is preferred by Eaton Transmis-

sion. The expansion tank (Marker A) is marked for proper fluid level. It should be checked when unit

is cold. Do not allow the unit to run low on oil. If the unit is low, you can add oil by removing the cap

(Marker B). Remove plug (Marker C) and fill transmission gearbox with 80-90 SAE Gear Oil to lower

edge of fill hole.

B

B

a

C