Tl-17, Tl-17a p – Metal Sales TL-21 User Manual

Page 2

PF/I-2

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

F

lush

F

ace

/ I

nterIor

l

Iner

s

erIes

Tl-17

and

Tl-17a P

anel

o

verview

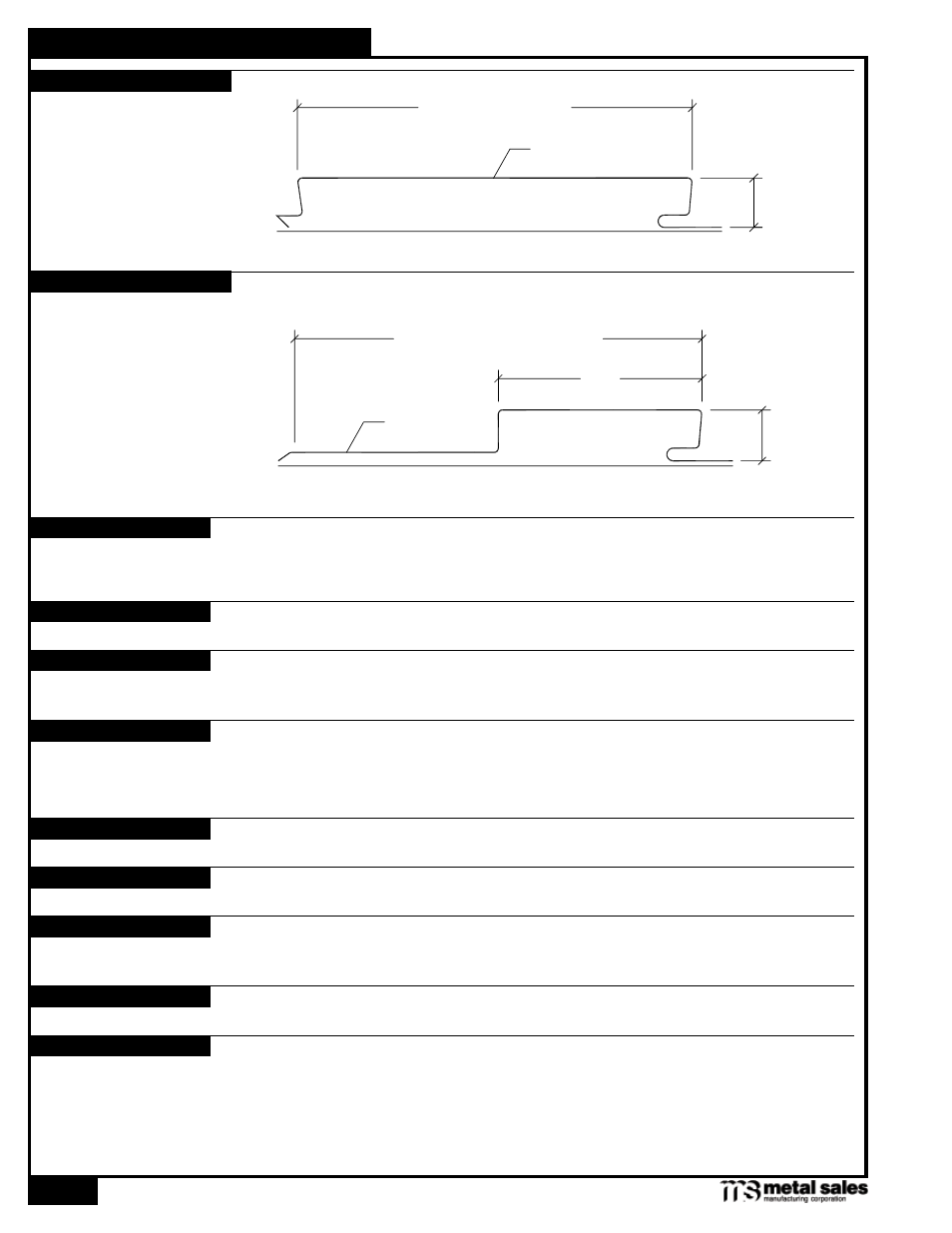

TL-17 PANEL PROFILE

TL-17A PANEL PROFILE

C

6"

1

1

/

2

"

12" Coverage

1

1

/

2

"

12" Coverage

C

SUBSTRATE

COVERAGE

LENGTH

AVAILABILITY

APPLICATION

FASTENING SYSTEM

FASTENERS

MATERIALS

FINISH

Flush Faced panels are available in a 12" width with 1

1

/

2

" heights.

Soffit, Fascia, Wall, Liner.

Flush Faced panel is designed to be utilized over open structural framing, but can easily be used with a solid

substrate. The recommended substrate is

5

/

8

" plywood with a 30 pound felt moisture barrier. To avoid panel

distortion, use a properly aligned and uniform substructure.

Lengths under 5'-0" are available with some cutting restrictions. Please consult your Metal Sales branch for

maximum panel lengths and recommendations (see PGI-2 and PGI-3 for locations).

Panels are available in 24 through 16 gauge. Minimum quantities may apply.

Custom capabilities include:

-Perforated panels for wind screens and liner panels.

-Depth of panel.

Direct Fastened (concealed).

The fastener selection guide should be consulted for choosing proper fasteners for specific applications. Quan-

tity and type of fastener must meet necessary loading and code requirements (see PGI-12-14).

Steel grade 50, per ASTM A-792. Optional material: stainless steel, weathering steel, copper, and aluminum.

*

Acrylic Coated Galvalume

®

(ACG) / ASTM A-792 - AZ55

Multi-Pass Kynar

Prepainted Galvalume / ASTM A-792 - AZ50

Marbilique

MS Colorfast45

®

Plastisol

**

Fluorocarbon (PVDF)

Polyester

*

Differential appearance of Acrylic Coated Galvalume roofing materials is not a cause for rejection.

**

Meets both Kynar 500 and Hylar 5000 specifications.