Delta rib – Metal Sales Delta Rib Manual User Manual

Page 7

PDR-7

DELTA RIB

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

D

esign

/ i

nsTallaTion

C

onsiDeraTions

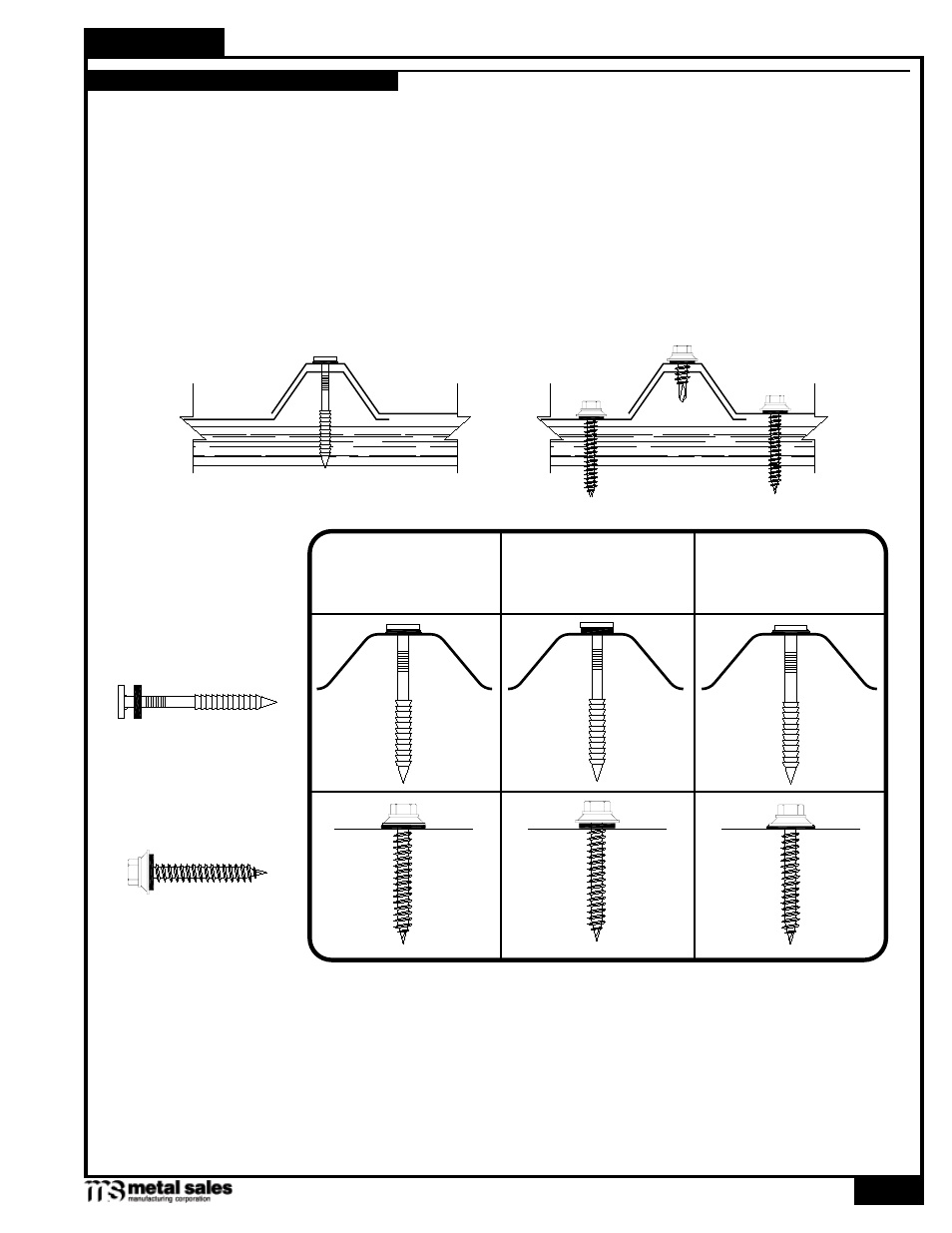

FASTENER INSTALLATION TECHNIQUE

USING NAILS:

If nails are used as a fastening method, it is best to use a painted or galvanized steel ring shank nail with a flat neoprene washer.

Nails should penetrate the wood support to a depth of at least

1

/

4

”, but should not be to long as to protrude completely through the

support. Nails must not be driven to tight. Overdriving may cause damage to washers and/or the steel sheet. Nails should be driven

perpendicular to the wood support, unless the manufacturer’s directs otherwise. Typically 1lb of nails should be used per square

for 2’ wide panels and 2 lbs of nails should be used per square for 3’ wide panels.

USING SCREWS:

If screws are used as a fastening method, it is best to use a painted or plated screw, Type A or driller tip with a flat rubber washer.

The correct screw gun is also important to the proper installation of self-drilling or self-tapping screws. A tool with the appropri-

ate speed and torque setting (as recommended by the fastener manufacturer) will help prevent fastener thread strip-out and pos-

sible damage to the panel or its coating. Typically 40 screws should be used per square for 2’ wide panels and 80 screws should be

used per square for 3’ wide panels.

USING NAILS

USING SCREWS

CORRECT

Sealing material slightly

visible at edge of washer.

Assembly is water tight.

TOO LOOSE

Sealing material is not

visible; not enough

compression to seal.

TOO TIGHT

Washer is deformed;

sealing material pressed

beyond fastener edge.

SEATING THE WASHER - Apply sufficient torque to seat the washer - do not overdrive the fastener.

TO PREVENT WOBBLING - Make sure fastener head is completely engaged in the socket. If the head does not go all

the way in the socket - tap the magnet deeper into the socket to allow full head engagement. Metal chips will build

up from drilling and should be removed from time to time.

PROTECT DRILL POINT - Push only hard enough on the screw gun to engage clutch. This prevents excess friction and burn

out of the drill point. Correct pressure will allow screw to drill and tap without binding.