Delta rib – Metal Sales Delta Rib Manual User Manual

Page 6

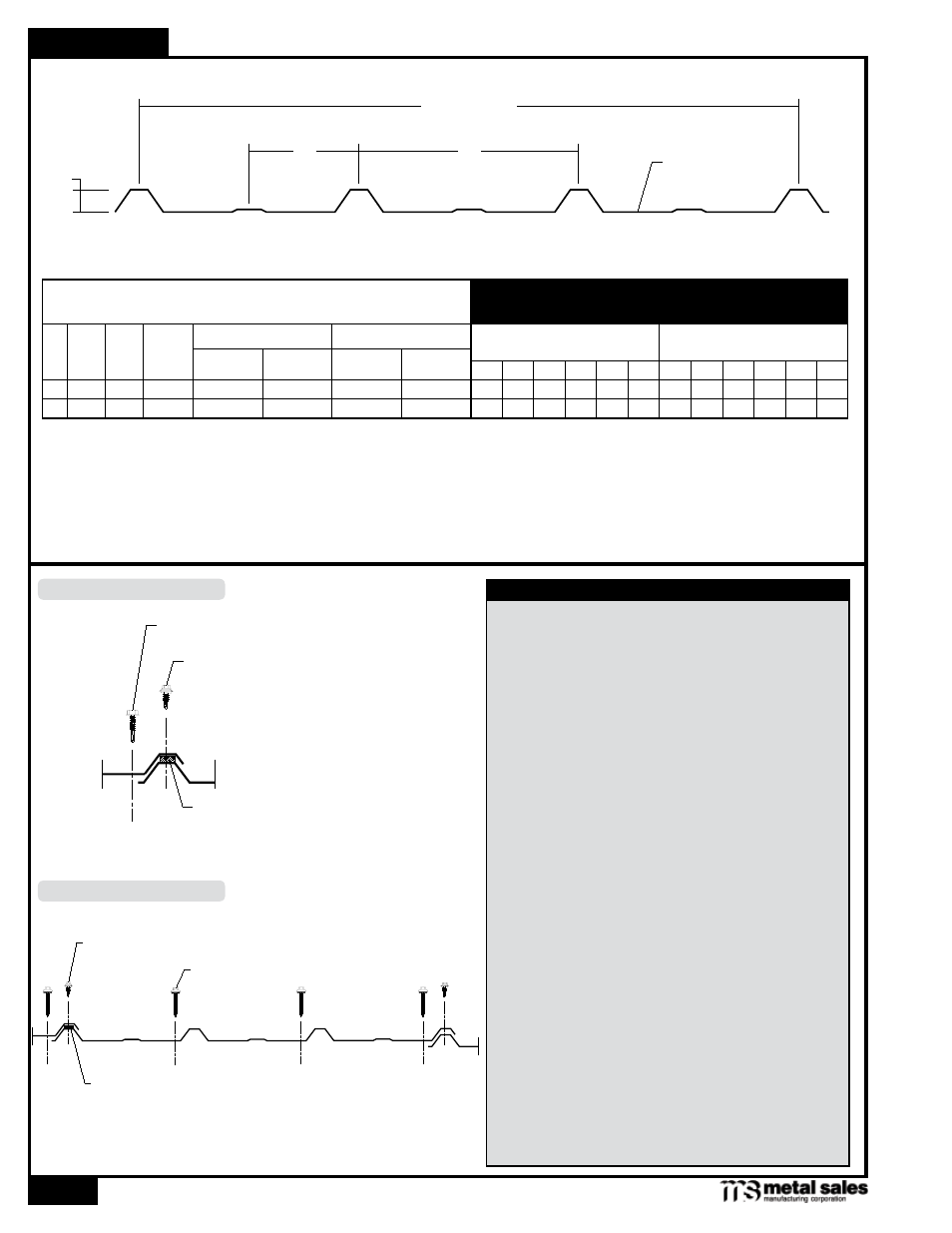

PDR-6

DELTA RIB

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

s

eCTion

P

roPerTies

anD

l

oaD

T

ables

13

/

16

"

8"

24" Coverage

4"

C

ALLOWABLE UNIFORM LIVE LOADS PSF

(3 or More Equal Spans)

2' 3' 4' 5' 6' 7' 2' 3' 4' 5' 6' 7'

SECTION PROPERTIES

Bottom in Compression

Width

(in.)

Yield

KSI

24"

80

24"

50

26

Ga.

24

Sxx

In

3

/ft

Ixx

In

4

/ft

Weight

PSF

0.80

1.05

Top in Compression

Sxx

In

3

/ft

Ixx

In

4

/ft

Inward (Gravity / Deflection)

Load

Outward Uplift (Stress)

Load

0.0160 0.0275 0.0135 0.0280

185 85 45 23 13 8 182 84 45 23 13 8

0.0230 0.0399 0.0190 0.0378

213 97 55 30 18 11 225 102 58 30 18 11

1. Theoretical section properties have been calculated per AISI 2001. “Specifications for the Design of Cold-formed Steel Structural Mem-

bers.” Ixx and Sxx are effective section properties for deflection and bending.

2. Allowable load is calculated in accordance with AISI 2001 specifications considering bending, shear, combined bending and sheer and

deflection. Allowable load considers the worst case of 3 and 4 equal span conditions. Allowable load does not address web crippling,

fasteners/support connection, or uplift testing. Panel weight is not considered.

3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.

4. Allowable loads do not include a 1/3 stress increase in uplift.

Slope

Substructure

Coverage

Length

Fasteners

Availability

GENERAL INFORMATION

The minimum recommended slope for Delta Rib roofing

panel is 3:12. Metal Sales recommends that in all roof appli-

cations, sealants and stitch screws be used on all sidelaps.

Delta Rib is designed to be utilized over open structural

framing, but can easily be used with a solid substrate.

To avoid panel distortion, use a properly aligned and

uniform substructure.

Delta Rib panels are available in a

13

/

16

" rib height with a

coverage width of 24".

Minimum factory cut length is 5'-0". Maximum recom-

mended panel length is 40'-0". Longer panels require addi-

tional consideration in packaging, shipping, and erection.

Please consult Metal Sales for recommendations.

The fastener selection guide should be consulted for choos-

ing the proper fastener for specific applications. Quantity

and type of fastener must meet necessary loading and code

requirements.

NOTE: All panels are subject to surface distortion due to

improperly installed fasteners. Over-driven fasteners will

cause stress and induce oil canning across the face of the

panel at or near the point of attachment.

Finishes: MS Colorfast45

®

and Acrylic Coated Galvalume

®

Gauge: 26 ga standard, 24 ga optional

Tape Sealant

(roof only)

1

/

4

"-14 x

7

/

8

" Stitch Screw

(roof only)

#9-15 Woodscrew

ATTACHMENT DETAIL

FASTENING PATTERN

Tape Sealant

(roof only)

1

/

4

"-14 x

7

/

8

" Stitch Screw (roof only)

#9-15 Woodscrew