Corrugated – Metal Sales 7/8 Corrugated User Manual

Page 7

P7/8-7

7

/

8

" CORRUGATED

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Office) • www.metalsales.us.com

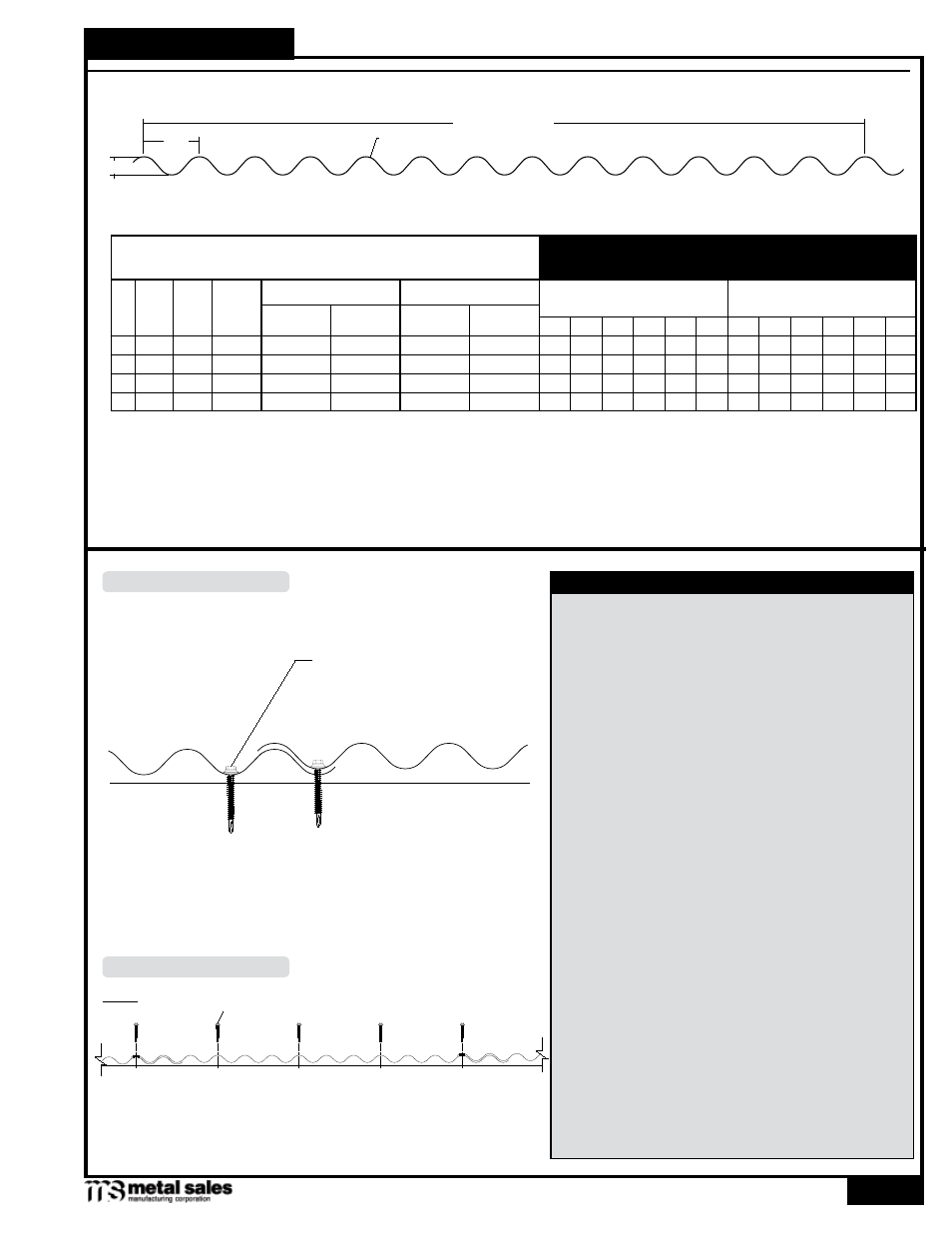

1. Section properties and allowable loads are calculated per AISI 2001 including 2004 Supplement.

2. Ixx and Sxx are effective section properties for deflection and bending

3. Allowable loads/spans are calculated considering bending, shear, combined bending and shear and deflection.

4. Allowable loads/spans calculations do not include consideration for web crippling, fastener / connection limitations or uplift testing.

5. Allowable loads/spans do not include a 1/3 stress increase.

6. Allowable loads for 24 ga. are based on ASTM E 330 test results attaching to 16 ga. girts

ALLOWABLE UNIFORM LIVE LOADS PSF

(3 or More Equal Spans)

2’ 3’ 4’ 5’ 6’ 7’ 2’ 3’ 4’ 5’ 6’ 7’

SECTION PROPERTIES

Bottom in Compression

Width

(in.)

Yield

KSI

34.67"

80

34.67"

50

34.67"

50

34.67"

33

26

Ga.

24

22

20

Sxx

In

3

/ft

Ixx

In

4

/ft

Weight

PSF

0.94

1.22

1.60

1.95

Top in Compression

Sxx

In

3

/ft

Ixx

In

4

/ft

0.0255 0.0580 0.0255 0.0580

386

156 66 34 20 8 386 156 66 34 20 8

0.0330

0.0744

0.0330

0.0744 175 151 127 102 78 30 175 151 127 102 78 30

0.0413 0.0956 0.0413 0.0955

530 241 107 55 32 13 530 241 107 55 32 13

0.0488 0.1146 0.0488 0.1146

419 191 108 64 37 16 419 191 108 64 37 16

Inward

Load

Outward

Load

Substructure

Coverage

Length

Fastener

Availability

GENERAL INFORMATION

WALL ATTACHMENT

FASTENING PATTERN

7/8" Corrugated panel is designed to be utilized over open

structural framing but can easily be used with a solid substrate.

To avoid panel distortion use a properly aligned and uniform

substructure.

7/8" Corrugated panel has a coverage width of 34

2

/

3

"

Minimum factory cut length is 3'-0". Maximum recommended

panel length is 45'-0". Longer panels require additional

consideration in packaging, shipping, and erection. Please

consult Metal Sales for recommendations.

The fastener selection guide should be consulted for choosing

the proper fastener for specific applications. Quantity and type

of fastener must meet necessary loading and code requirements

NOTE: All panels are subject to surface distortion due to

improperly applied fasteners. Overdriven fasteners will cause

stress and induce oil canning across the face of the panel at or

near the point of attachment.

Finishes: Bare galvanized, MS Colorfast45

®

, PVDF, Weathering

Steel, and Acrylic Coated Galvalume

®

Gauges: 26ga, 24ga, 22ga, and 20ga

WALL

#12-14 Self Driller

2

2

/

3

"

34

2

/

3

" Coverage

7

/

8

"

C

s

eCTion

P

roPerTies

& g

eneral

i

nformaTion

(w

all

P

anel

)