Technical data – Marshalltown Truss Screed User Manual

Page 8

8

OPERATIONS

SECTION 1

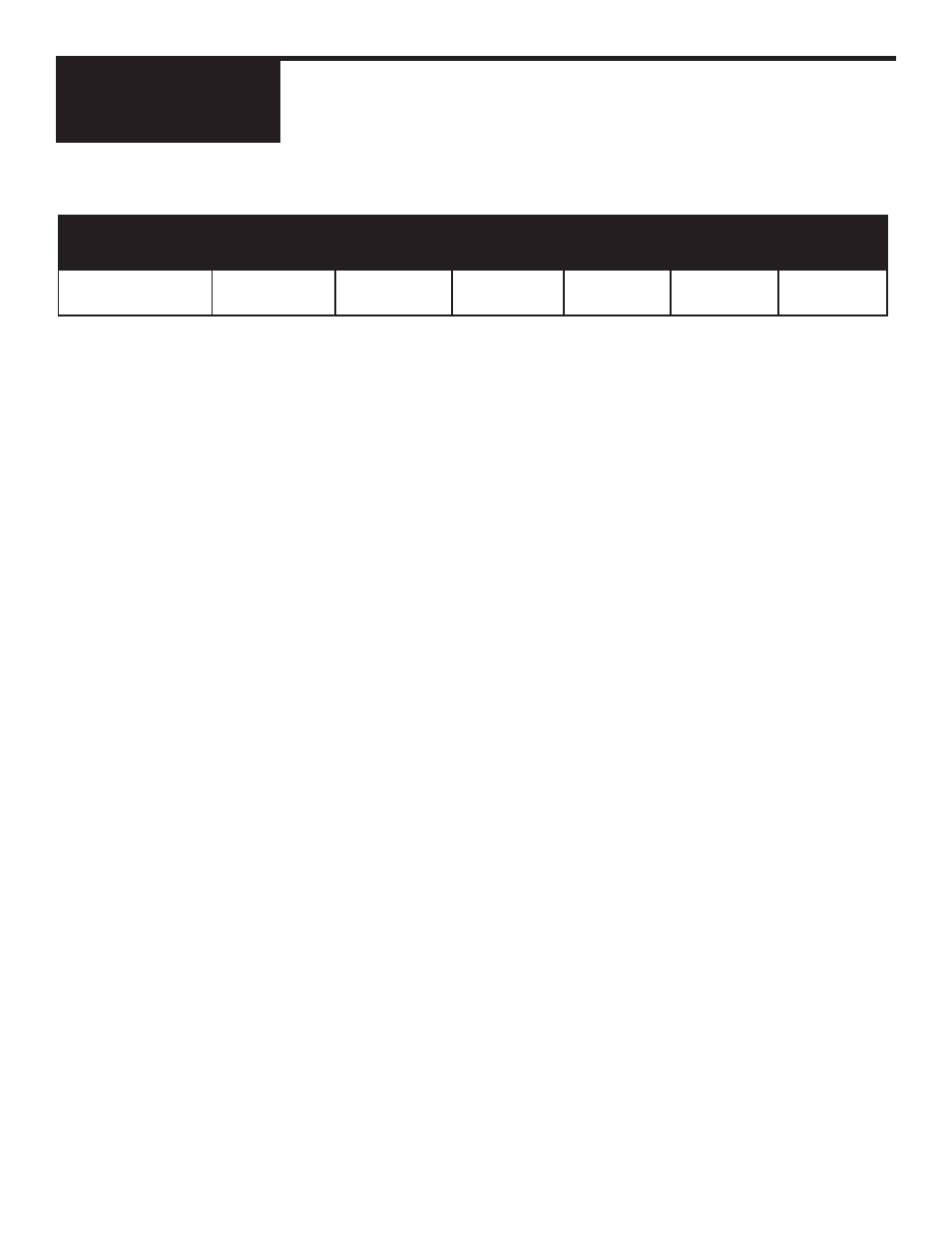

SPECIFICATIONS ON THE MARSHALLTOWN TRUSS SCREED

Truss Blades

10'

7 1/2'

5'

2 1/2'

2'

Max Width

10 GA. Galv. Steel

180lbs. (64kg)

135lbs. (47kg)

90lbs. (32kg)

50lbs. (16kg) 36lbs. (13kg)

65'

• Top pipe - coupling system - fine thread adjustment 1 5/16-16 tpi with full flow 1” non-restricting air system with dual locking jam nuts.

• Vibration proof welds with exclusive vibration-dampening system.

• Bolt-on blades with quick connecting splice plates front and back at each truss section using 1/2-13 nuts and bolts throughout.

• Balanced design truss height to overall base width provides equilateral triangle strength for obtaining precise grade control

and structural integrity.

• Top pipe coupling system provides for crowned or invert slab section without loosening bottom splice blade bolts. Special crowns

or inverts are obtainable with ball joint top pipe coupler or crown invert bracket. The coupler bracket must be special ordered

from MARSHALLTOWN.

• NOTE: select screed width to allow minimum overhang past forms; 6” overhangs are ideal, overhangs over 12" are

not recommended

• NOTE: special make truss screeds are available upon request. Most special make screeds can be available in 4-6 weeks.

TECHNICAL DATA