Marshalltown Truss Screed User Manual

Page 12

12

OPERATIONS

SECTION 1

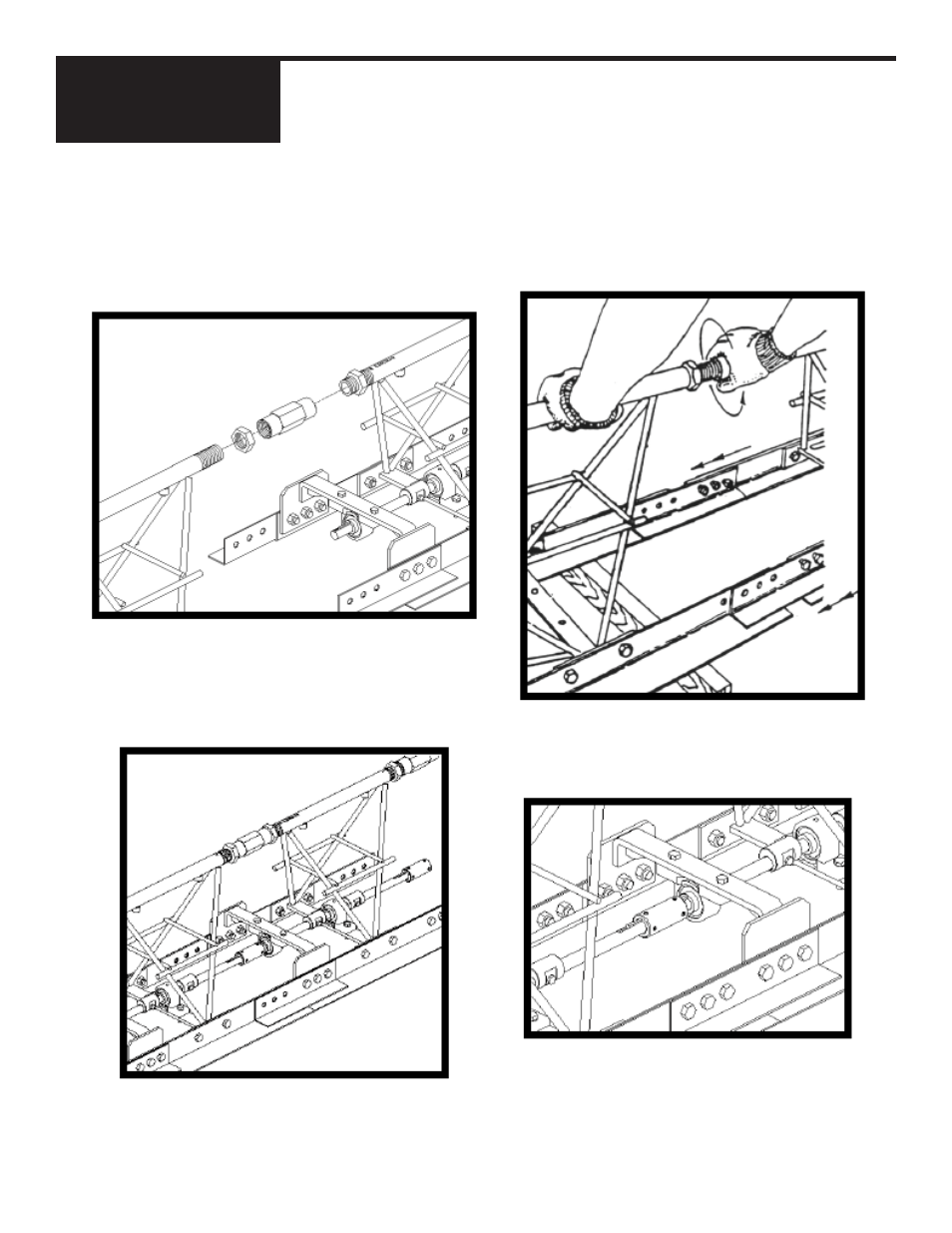

The following figures describe the proper instructions for correctly assembling engine driven screed. Make sure that you follow the

instructions in order. If the assembling of your screed is not done in this order, there could be some problems in trying to maintain floor

flatness because your screed is not level. Levelness of your screed is critical!

SECTION ASSEMBLY

STEP 1: Screw jam nuts onto top pipe. Start the top pipe coupler

onto the top pipe of the mating truss section. Only thread the

coupler on about three turns.

NOTE: The right and left hand jam nuts will already be installed

on the screed section.

TIGHTEN JAM NUTS AFTER SCREED IS LEVEL

STEP 2: Slide screed sections together until top pipe

threads on screed marked “R” line up with threads in

coupler on the screed. Start coupler on adjoining threads

by hand to prevent cross threading.

STEP 3: Bearing support bolts should be loose so

that splice plate can move in clearance holes. With 15”

adjustable wrench, turn top pipe coupler until screed

and bull float blades contact, then back the coupler off

slightly so that the blades touch without tension.

STEP 4: Tighten bolts on splice plates. Next slide the

shaft coupler onto the adjoining section and tighten the

set screws provided. Make sure that the 3/16 key is on the

shaft before sliding sections together. Repeat these steps

for attaching all engine driven screed sections.