Ti.224.225-08_pg4, Rohs, Technical information – MAMAC Systems HU-225 User Manual

Page 4: Humidity sensor, Page 4 of 4

Model HU-224/225

Technical Information

TI.224/225-08

HUMIDITY SENSOR

Page 4 of 4

CHECKOUT

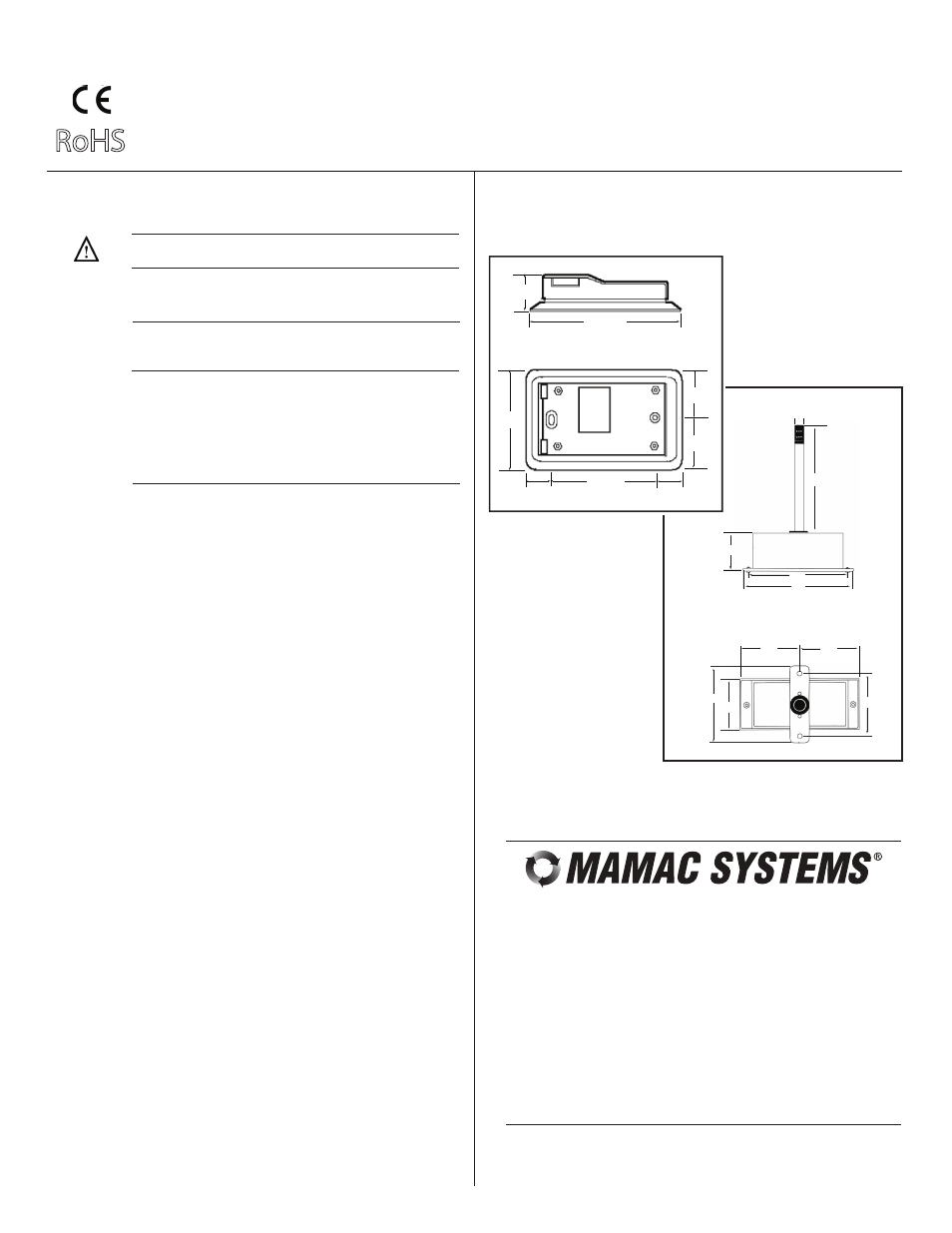

DIMENSIONAL DATA

CALIBRATION

1. Verify that the unit is mounted in the correct position.

2. Verify appropriate input signal and supply voltage.

3. Verify appropriate configuration range.

CAUTION: Never connect 120 VAC to these transducers.

Never connect AC voltage to a unit intended for DC supply.

Transducer

Operation

Calibration of HU-224/225-2/3-mA/VDC Humidity

Transducer

Field calibration instructions are provided with the following

precautions and advice:

1. Do not verify comparative RH with a sling Psychrometer.

There are far too many variables which induce errors into

this process. New HU-224/225 RH transducers are already

supplied with calibration.

2. Recalibration must be done in a controlled environment.

Relative humidity must be held stable while making any

adjustment.

3. Verify the output from the device directly with calibrated

instrumentation and verify the RH with calibrated instrumen-

tation, (NOT A CONTROLLER OUTPUT). With the correct

power applied and only a meter connected to the output of

the transducer, ensure that the output is proportional to the

true RH.

4. A)

SINGLE-POINT CALIBRATION:

[NOTE: SELECT EITHER OPTION 1 OR OPTION 2,

BUT NOT BOTH.]

Option 1. Select a controlled humidity environment

between 10 & 40% RH. Insure humidity is

stable and adjust zero trimmer (Z).

Option 2. Select a controlled humidity environment

between 40 & 70% RH. Insure humidity is

stable and adjust span trimmer (S).

B)

TWO-POINT CALIBRATION: Select a controlled

humidity environment between 10 & 40% RH. Insure

humidity is stable and adjust zero trimmer (Z).

Then select a controlled humidity environment between

70 & 75% RH. Insure humidity is stable and then adjust

span trimmer (S).

All units are factory calibrated to meet or exceed published

specifications. If field adjustment is necessary, follow the

instructions below.

MAINTENANCE

Regular maintenance of the total system is recommended to

assure sustained optimum performance.

FIELD REPAIR

None. Replace with a functional unit.

WARRANTY

See Data Sheet for additional information.

Figure 6 – HU-224/225 Humidity Transducer dimensions shown in inches and

millimeters (mm).

NOTE: The HU-224/225 is a highly accurate device. For

applications requiring a high degree of accuracy, the use of

laboratory-quality meters and gauges are recommended.

TI.224/225-08

RoHS

4.50" (114.31)

1.00"

(25.40)

3.25" (82.55)

.625"

(15.87)

.625"

(15.87)

2.75"

(69.85)

1.375"

(34.92)

1.375"

(34.92)

Wall Mount

HU-225

Duct Mount

HU-224

4.00"

(101.6)

2.63"

(66.8)

3.25"

(82.55)

2.81"

(71.37)

2.81"

(71.37)

5.00"

(127.0)

5.63"

(143.0)

.50"

(12.7)

2.00"

(50.8)

6.00"

(152.4)

For Technical / Application Assistance call your nearest office

8189 Century Boulevard • Minneapolis, MN 55317-8002 • USA

800-843-5116 • 952-556-4900 • Fax 952-556-4997

[email protected] • www.mamacsys.com

EUROPE

4200 Waterside Centre

Solihull Parkway

Birmingham • West Midlands

B37 7YN • United Kingdom

01384-271113 • Fax 01384-271114

AUSTRALIA

4 Armiger Court, Unit 2

Adelaide • S.A.

5088 • Australia

08-8395-4333 • Fax 08-8395-4433

CANADA

675 Cochrane Drive

East Tower • 6th Floor

Toronto • Ontario

L3R 0B8 • Canada

905-474-9215 • Fax 905-474-0876

ASIA

1 Fullerton Road #02-01

One Fullerton

Singapore • 049213

65-31581826 • Fax 65-31581826

MAMAC Systems, Inc., reserves the right to change any specifications

without notice to improve performance, reliability, or function of our products.