4) reliability test method, Mechanical – Mag Layers USA MCM-9070M User Manual

Page 3

(4) RELIABILITY TEST METHOD

MECHANICAL

TEST ITEM

SPECIFICATION

TEST DETAILS

Solder ability

The product shall be connected to the test

Apply cream solder to the printed circuit board .

circuit board by the fillet (the height is 0.2mm).

Refer to clause 8 for Reflow profile.

Resistance to

There shall be no damage or problems.

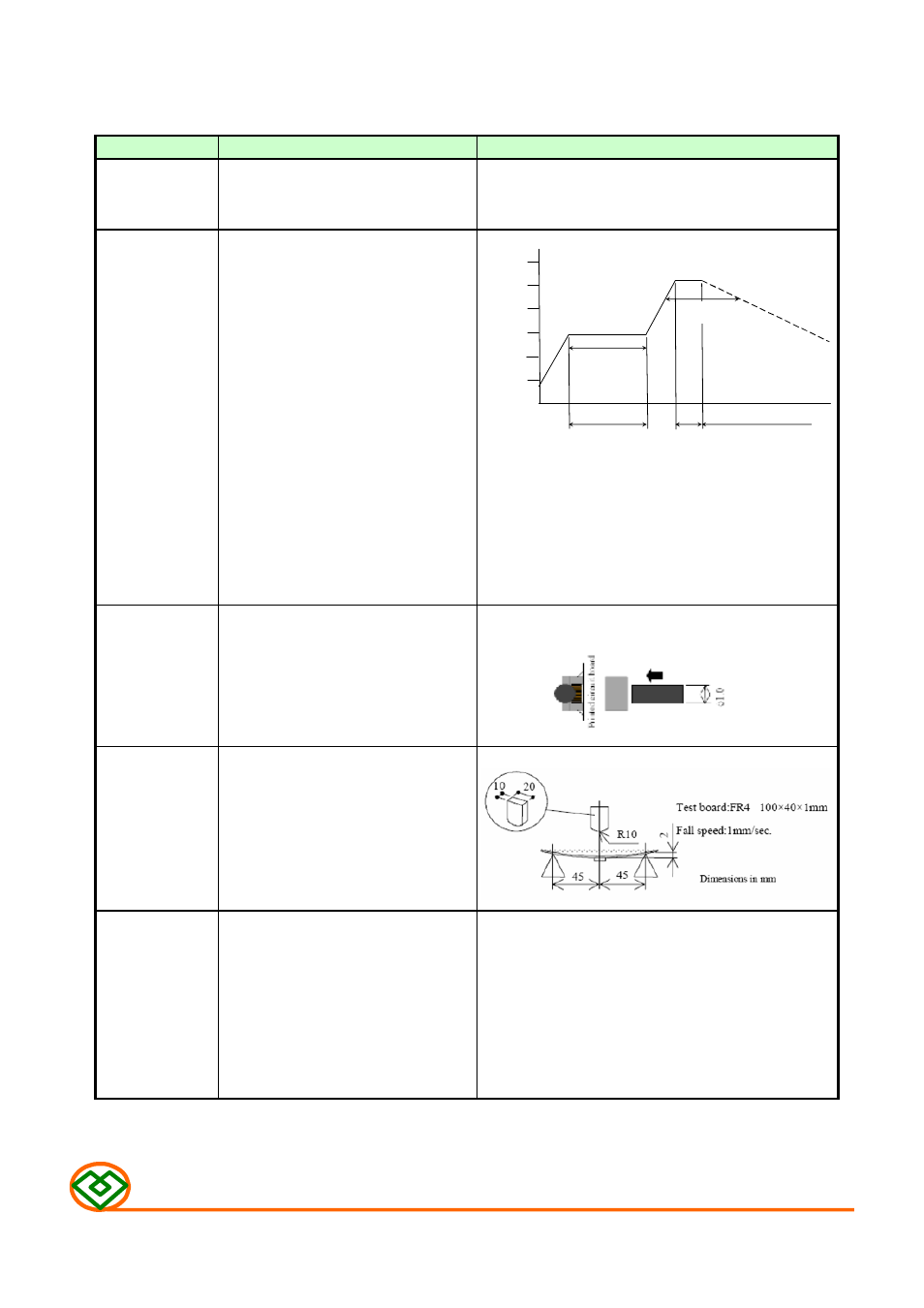

Temperature profile of reflow soldering

Soldering heat

(reflow soldering)

The specimen shall be passed through the reflow oven

with the condition shown in the above profile for 1 time.

The specimen shall be stored at standard atmospheric

eric conditions for 1 hour, after which the measurement

shall be made.

Terminal strength

The terminal electrode and the ferrite must

Solder a chip to test substrate , and then laterally apply

not damaged.

a load 9.8N in the arrow direction.

Strength on PC board The terminal electrode and the ferrite must

Solder a chip to test substrate and then apply a load.

bending

not damaged.

High

Impedance:Within

±20% of the initial value.

After the samples shall be soldered onto the test circuit

temperature

Insulation resistance and DC resistance on the board,the test shall be done.

resistance

specification(refer to clause 2-1) shall be met.

Measurement : After placing for 24 hours min.

The terminal electrode and the ferrite must not Temperature : +85

±2℃

damaged.

Applied voltage : Rated voltage

Applied current : Rated current

Testing time : 500

±12 hours

MCM-9070M-SERIES

Page 3/8

M A G .L A Y E R S

Sodering temperature (

℃

)

soldering

(Peak temperature 260±3℃ 10 sec

Slow cooling

(Stored at room

temperature)

30 sec Min

(230

+0

℃)

300

250

200

150

100

50

2 min

10

sec.

2 min. or more

Pre-heating

150 ~ 180℃