Lightforce LED 215 User Manual

Lightforce led215, Instruction data

LIGHTFORCE LED215

LIGHTFORCE AUSTRALIA PTY LTD • 28 Orsmond Street, Hindmarsh SA 5007 Australia • www.lightforce.com | email: [email protected]

Australia: Tel: 08 8440 0888 | Fax: 08 8346 0504 • Int’l: Tel: +618 8440 0888 | Fax: +618 8346 0504

All logos and images are subject to relevant trademark and copyright protection LIGHTFORCE Pty Ltd | © July 2014 • Data and specifications contained maybe subject to change without notice.

LIGHTFORCE Australia Pty Ltd shall not be liable for damage, malfunction, failure resulting from accident, misuse, misapplication, unauthorised repair, neglect, modification, unauthorised or non standard replacement parts,

accessories, bulbs, batteries or voltage or operation of the product beyond its technical and or environmental specification.

INSTRUCTION DATA

PRODUCT: LED215

VER: 1.1

DATE: JULY 2014

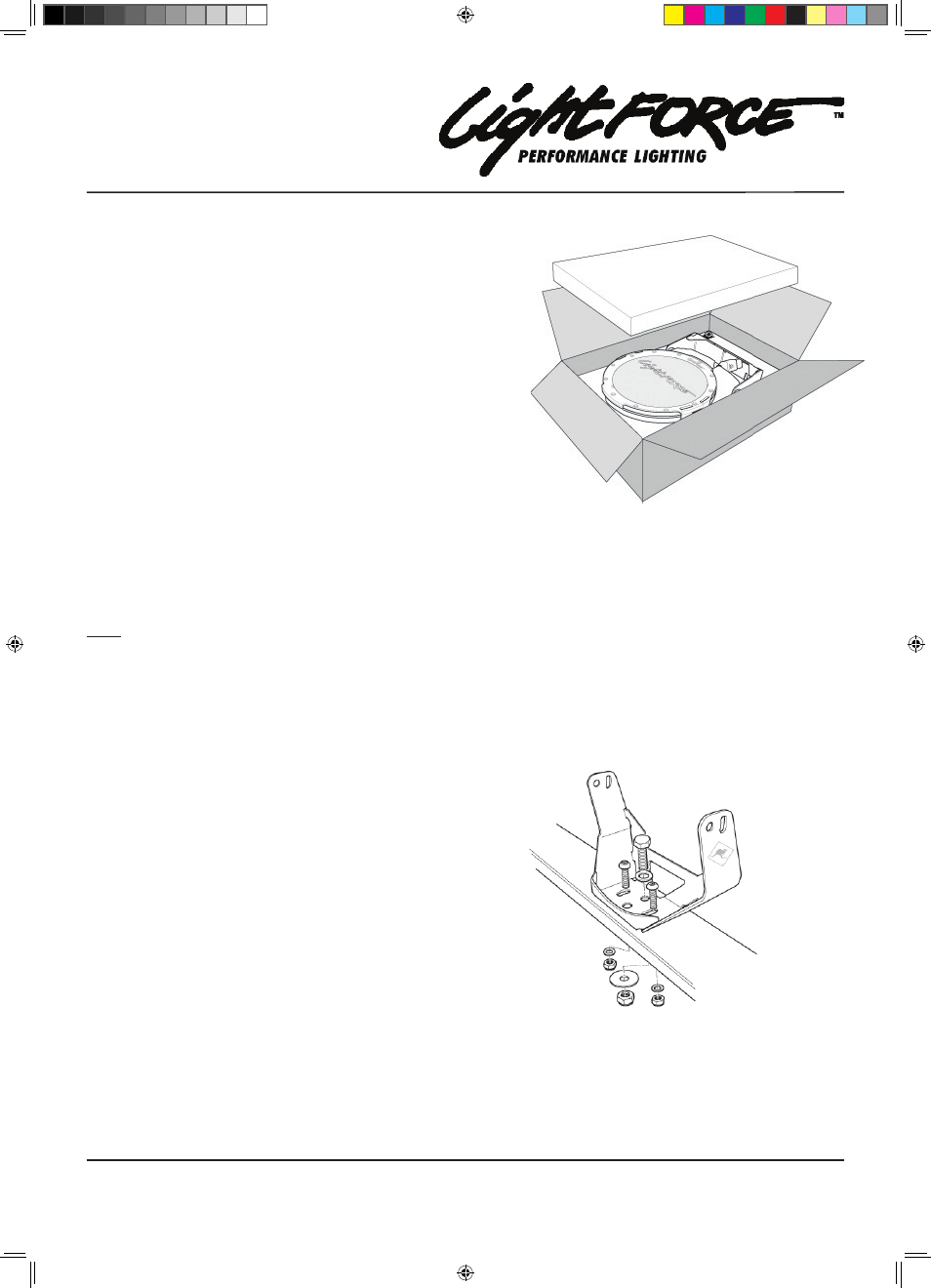

KIT CONTENTS:

1 x LED215 light

1 x Clear filter (fitted to light)

1 x Stainless steel mounting bracket

2 x M8 x 30mm stainless steel Torx bolts with washers (fitted to light)

2 x M6 stainless steel Hex bolts with washers (fitted to light)

2 x M8 Torx bolts, washers and Nylock nuts

1 x M10 x 40mm stainless steel bolt

1 x M10 x 20mm stainless steel washer

1 x M10 x 38mm stainless steel washer

1 x M10 Nylock nut

1 x Hex key

1 x Torx Key

1 x 4 pin Deutsch waterproof connector

1 x user instructions

INSTALLATION GUIDE:

TOOLS REQUIRED:

• 17mm socket on ratchet

• 17mm ring spanner

• Torque wrench

GENERAL CARE AND SAFETY TIPS:

To wash your lights, use plenty of warm soapy water and a soft cloth only (this prevents the surface from marking).

Never use any solvent based cleaners or industrial detergents when cleaning theses lights.

IMPORTANT NOTE: Before fitting the stainless steel hardware apply a small amount of anti-seize to the threads of all bolts.

NOTE: Mounting points very in design and load capacity ensure the light is within manufactures recommended weight

specifications before fitment.

WARNING:

The bolts that retain the mount to the light cannot exceed 30mm (1.20”) in length otherwise damage to the housing can occur.

MOUNTING BRACKET:

Locate the bracket in a suitable position using the M10 X 40mm

bolt and 20mm washer, fit the washer to the bolt first then pass

through the bracket and mounting point then fit the larger

washer and M10 Nylock nut until finger tight, then complete

the remainder using a ring 17mm spanner and 17mm socket

& ratchet (do not use rattle guns).

NOTE:

The two supplied M8 Torx mounting bolts are for extra mounting

security or if you have a problem with your light rotating, there

are two curved mounting slots either side of the main M10

mounting positions.

MOUNTING LIGHT TO BRACKET:

Using the tools provided, first remove the four button head bolts from the side of the light ensuring that the captive bolts are

retained within the housing.

Feed the 4 pin cable through the opening located at the back of the bracket.

Then slide the light on aligning the holes of the mount to the holes on the body of the light ensuring the small black spacer is

fitted between the body of the light and inside of the bracket.

Insert a single M8 bolt in each side first then insert the two smaller M6 bolts tighten all until the light holds position (do not

completely tighten until the light has been aligned to the required position).

LED215.indd 1

31/07/2014 3:56:57 PM