3 troubleshooting and fault elimination, 1 maloperation of the drive, Troubleshooting and fault elimination – Lenze EDK82MVXXX User Manual

Page 9: 3troubleshooting and fault elimination, Maloperation of the drive

Troubleshooting and fault elimination

Maloperation of the drive

9

l

EDK82MVXXX EN 1.0

3

Troubleshooting and fault elimination

3.1

Maloperation of the drive

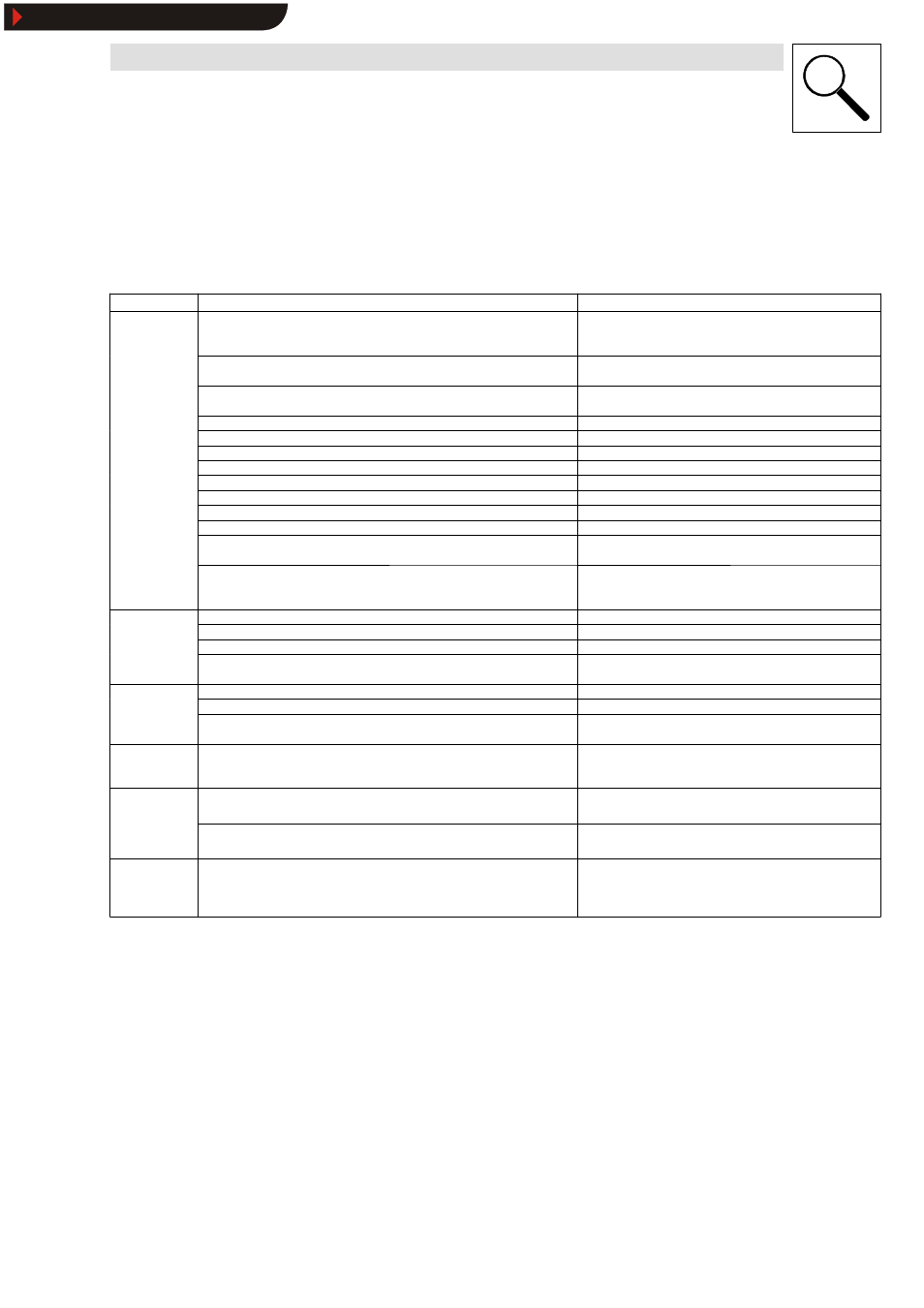

Fault

Cause

Remedy

Motor does not

rotate

DC-bus voltage too low

(Red LED is blinking every 0.4 s;

keypad display

LU

)

Check mains voltage

Controller inhibited

(Green LED is blinking, keypad display:

c

)

Remove the controller inhibit, controller inhibit can be set

through several sources

Automatic start inhibited (C0142 = 0 or 2)

LOW-HIGH edge at X3/28

If necessary, correct start condition (C0142)

DC injection brake active (DCB)

Deactivate DC-injection brake

Mechanical motor brake is not released

Manual or electrical release of mechanical motor brake

Quick stop (QSP) active (keypad display:

c

)

Remove quick stop

Setpoint = 0

Setpoint selection

JOG setpoint activated and JOG frequency = 0

JOG setpoint selection (C0037 ... C0039)

Active fault

Eliminate fault

Wrong parameter set active

Change to correct parameter set via terminal

Control mode C0014 = -4-, -5-, but no motor parameter identification

Motor parameter identification (C0148)

Under C0410 several functions, which exclude each other, are assigned to the

same signal source.

Correct configuration in C0410

Use internal voltage source X3/20 for function modules Standard-I/O, INTERBUS,

PROFIBUS-DP or LECOM-B (RS485):

Bridge between X3/7 and X3/39 is missing

Jumper terminals

Motor does not Defective motor cable

Check motor cable

Motor does not

rotate smoothly Maximum current too low (C0022, C0023)

Adaptation to application

rotate smoothly

Motor underexcited or overexcited

Check parameter setting (C0015, C0016, C0014)

C0084, C0087, C0088, C0089, C0090, C0091 and/or C0092 are not adapted to

the motor data

Manual adaptation or identification of motor parameters

(C0148)

Current

Setting of C0016 too high

Correct setting

Current

consumption of Setting of C0015 too low

Correct setting

consumption of

motor too high C0084, C0087, C0088, C0089, C0090, C0091 and/or C0092 are not adapted to

the motor data

Manual adaptation or identification of motor parameters

(C0148)

Motor rotates,

setpoints are

“0”

With the function

j

of the keypad a setpoint has been selected.

Set the setpoint to ”0” by C0140 = 0

Motor

parameter

identification

Motor too small compared with rated power

identification

stops with error

LP1

DC brake active via terminal

Unacceptable

drive response

with vector

control

various

Vector control optimisation

Show/Hide Bookmarks