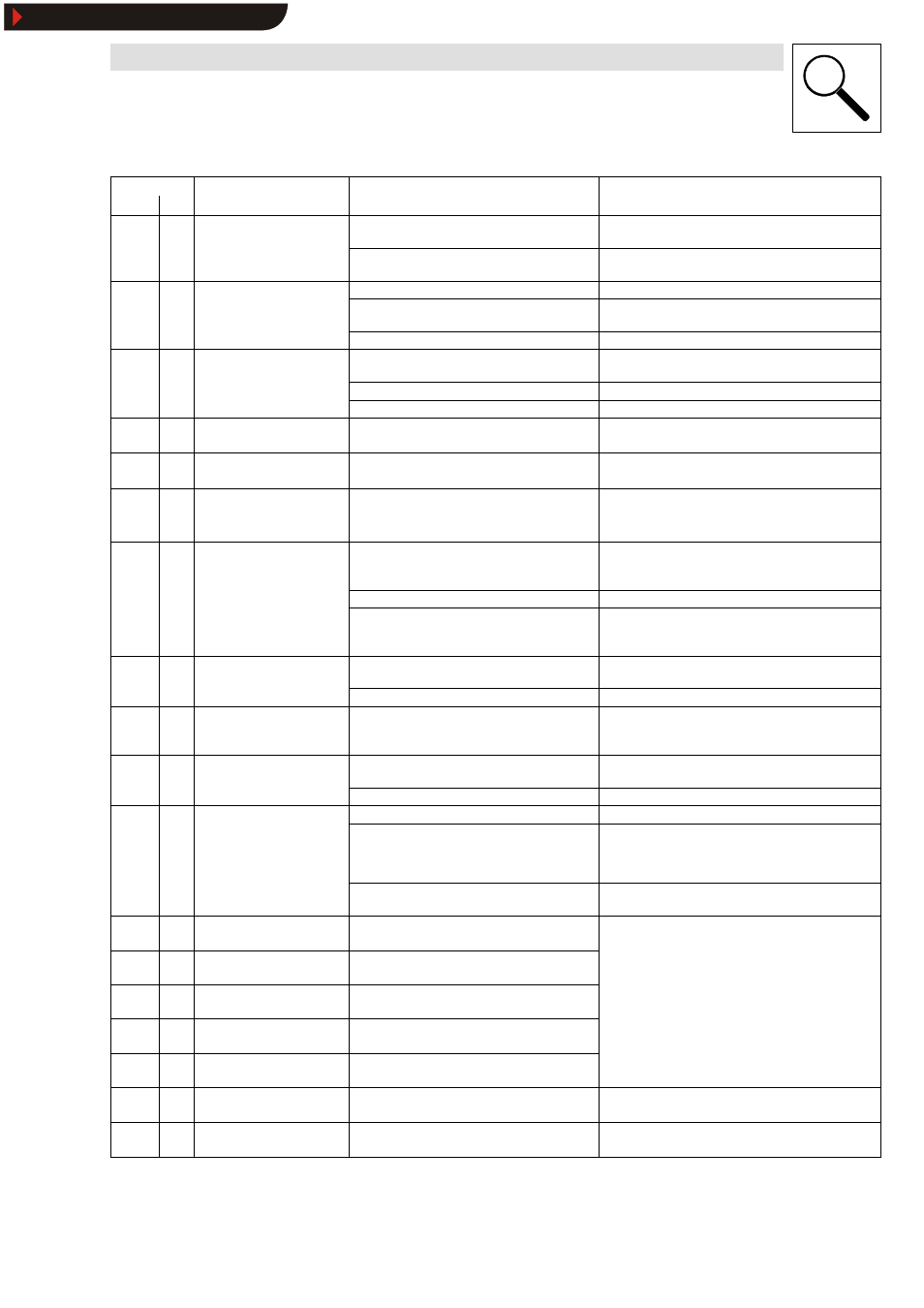

Troubleshooting and fault elimination, Error messages – Lenze EDK82MVXXX User Manual

Page 11

Troubleshooting and fault elimination

Error messages

11

l

EDK82MVXXX EN 1.0

Display

Remedy

Cause

Fault

Keypad PC

1)

OC1

a

11

short-circuit

short-circuit

•

Find reason for short circuit; check motor cables

•

Check brake resistor

a

Excessive capacitive charging current of the motor

cable

Use shorter/low-capacity motor cables

OC2

12

Earth fault

Grounded motor phase

Check motor, check motor cable

OC2

a

Excessive capacitive charging current of the motor

cable

Use shorter/low-capacity motor cables

Earth fault detection can be deactivated for checking

OC3

a

13

Overload inverter during

acceleration or short circuit

Acceleration time (C0012) too short

•

Increase acceleration time

•

Check drive selection

a

Defective motor cable

Check wiring

Interturn fault in the motor

Check motor

OC4

a

14

Overload controller during

deceleration

Deceleration time too short (C0013)

•

Allow longer deceleration time

•

Check the external brake resistor selection

OC5

a

15

Controller overload in

stationary operation

Long and frequent overload periods

Check drive selection

OC6

16

Motor overload (I

2

x t overload) Motor thermally overloaded by for instance

OC6

a

(

)

•

impermissible continuous current

•

Check drive selection

•

frequent or too long acceleration processes

•

Check setting under C0120

OH

a

50

Heatsink temperature > +85

°C

Ambient temperature T

amb

> +60

°C

•

Allow controller to cool down and ensure better

ventilation

•

Check ambient temperature

OH

-

Heatsink temperature > +80

°C

Heat sink very dirty

Clean heat sink

OH

e

p

°C

Impermissible high current or frequent and long

acceleration processes

•

Check drive selection

•

Check load, if necessary replace sluggish, defective

bearings

OH3

a

53

PTC monitoring (TRIP)

(only generated if C0119 = 1

4)

Motor too hot because of impermissibly high

current or frequent and long acceleration processes

Check drive selection

a

( y g

or 4)

PTC not connected

Connect PTC or switch-off monitoring (C0585=3)

OH4

a

54

Controller overtemperature

Controller inside too hot

•

Reduce controller load

•

Improve cooling

•

Check fan in the controller

OH51

203 PTC monitoring

(only generated if C0119 = 2

)

Motor too hot because of impermissibly high

current or frequent and long acceleration processes

Check drive selection

( y g

or 5)

PTC not connected

Connect PTC or switch-off monitoring (C0585=3)

OU

1020 DC-bus overvoltage

Mains voltage too high

Check voltage supply

OU

c

g

Braking operation

•

Prolong deceleration times.

•

For operation with external brake resistor:

– Check dimensioning, supply and connection of brake resistor

– Increase the deceleration times

Earth leakage on the motor side

Check motor cable and motor for earth fault (disconnect

motor from inverter)

Pr

a

75

Faulty parameter transfer when

using the keypad

All parameter sets are faulty

It is absolutely necessary to repeat the data transfer or

load the factory setting before the controller is enabled.

Pr1

a

72

Faulty transmission of PAR1

when using the keypad

PAR1 is faulty.

Pr2

a

73

Faulty transmission of PAR2

when using the keypad

PAR2 is faulty.

Pr3

a

77

Faulty transmission of PAR3

when using the keypad

PAR3 is faulty.

Pr4

a

78

Faulty transmission of PAR4

when using the keypad

PAR4 is faulty.

Pr5

a

79

Internal fault

Contact Lenze

Pt5

a

81

Time error during parameter

set transfer

Data flow interrupted by keypad or PC, e. g. keypad

disconnected during data transmission.

It is absolutely necessary to repeat the data transfer or

load the factory setting before the controller is enabled.

Show/Hide Bookmarks