3 preparation, Preparation, Mechanical installation – Lenze g500-H helical gearbox User Manual

Page 13

Mechanical installation

Preparation

General information about the assembly of drive systems

EN

13

Lenze ¯ MA 12.0012 ¯ 1.0

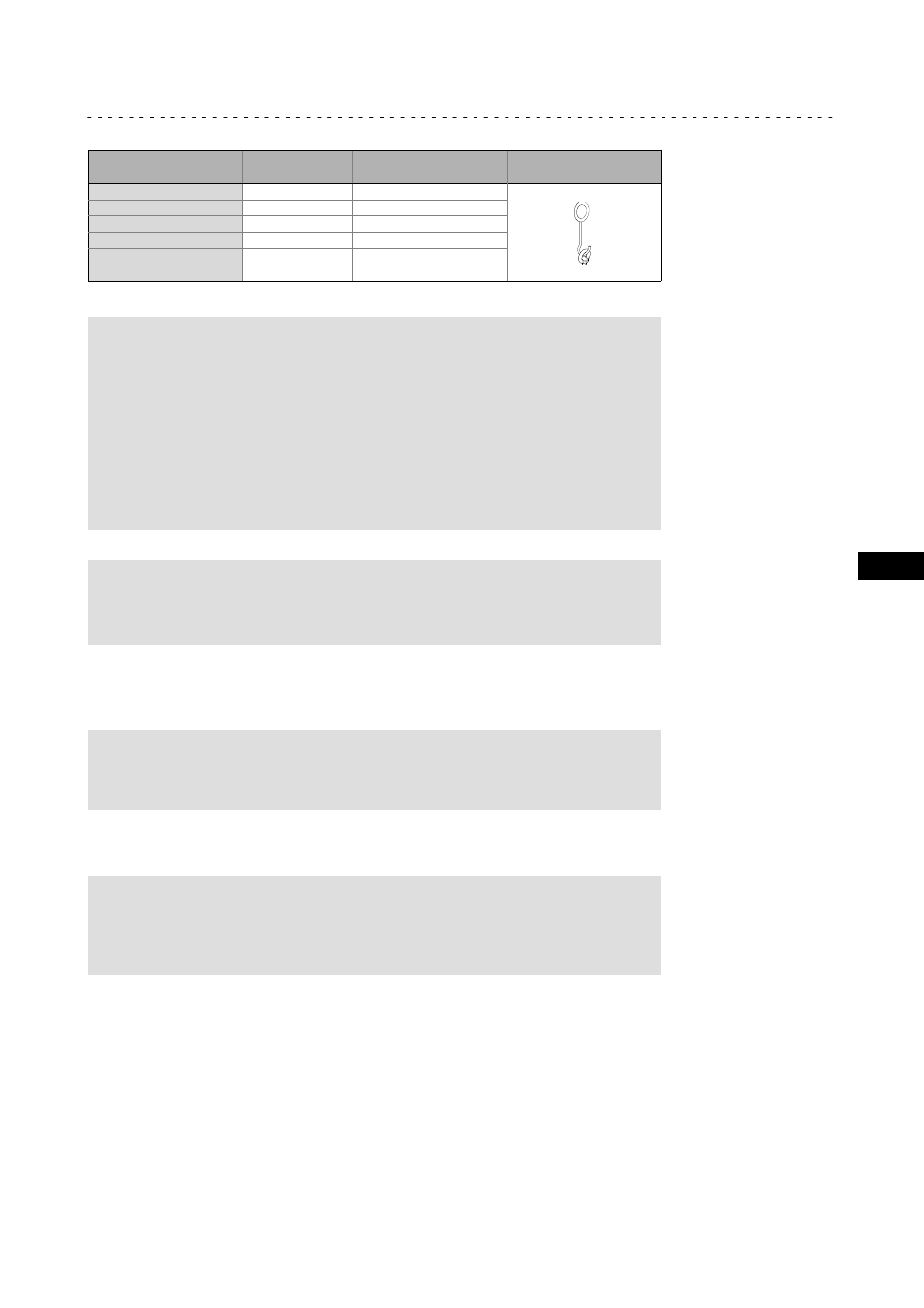

Gearbox type/size

Thread

max. payload

Eye bolt according to

DIN 580

g500−H45

M6

80

g500−H100

M6

80

g500−H140

M8

140

g500−H210

M8

140

g500−H320

M10

230

g500−H450

M12

340

Tab. 2

Load carrying capacity of eye bolt in kg

}

Danger!

Completely screw in transport aids (such as eye bolts or bearing plates),

they must be flat and applied over their entire surface!

If possible, the transport aids (such as eye bolts or bearing plates) must

be stressed vertically in the direction of the screw axis! Angular tension or

tension to the sides reduces the payload! Observe the information

provided in the DIN 580!

Use additional appropriate lifting aids, if required, to achieve a direction

of loading which is as vertical as possible (highest payload). Secure lifting

aids against shifting!

(

Stop!

Observe load carrying capacity!

Staying under floating load is prohibited!

4.3

Preparation

)

Note!

Thoroughly remove anticorrosion agents from output shafts and flange

faces.

4.3.1

General information about the assembly of drive systems

(

Stop!

The lubricant fill quantity of the gearboxes is matched to the mounting

position. The mounting position indicated on the nameplate must be

observed to avoid damage to the gearbox.