Diameter detection with a distance sensor, Application examples, 6 diameter detection with a distance sensor – Lenze EVF9383 User Manual

Page 182

Application examples

Diameter detection with a distance sensor

3−12

l

EDSVF9383V−EXT EN 2.0

3.6

Diameter detection with a distance sensor

This application is based on the basic configuration C0005 = 8000.

M

M

Q

R

S

V

T

U

W

X

Fig. 3−7

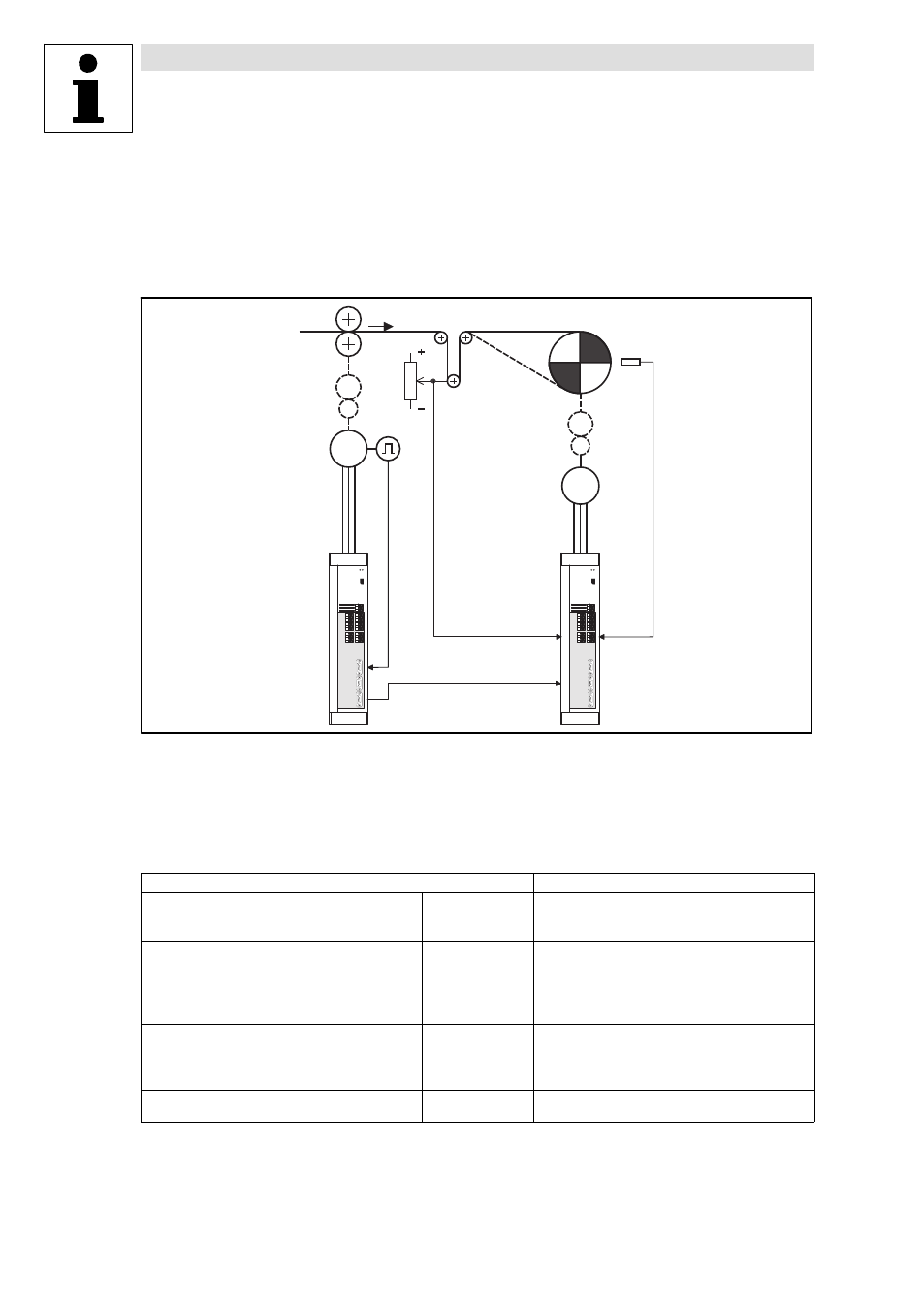

Basic structure of a dancer position control with external diameter detection via a distance sensor

Line speed (material speed)

Dancer

Winder

Material guide for CW rotation of the winder

Material guide for CCW rotation of the winder

Distance sensor (detects the distance to the winding surface)

Actual dancer position

Digital frequency of material speed

Input and output assignment

Winding drive

Digital frequency input

X9

·

Line speed (material speed)

Analog input

X6/1,2

·

Actual dancer position

X6/3,4

·

Signal from distance sensor

Digital inputs

X5/28

·

Controller enable

X5/E1, X5/E2

·

Direction of rotation/quick stop

X5/E3

·

Loading the actual value

X5/E4

·

Reset of dancer position controller

X5/E5

·

TRIP reset

Digital outputs

X5/A1

·

Error (TRIP)

X5/A2

·

Actual dancer position = setpoint

X5/A3

·

Ready for operation (RDY)

X5/A4

·

D

min

/D

max

reached

Analog outputs

X6/62

·

Actual speed

X6/63

·

Motor current

The analog input X6/3,4 (AIN2) is assigned with the signal of the diameter detection. If a distance

sensor is used to detect the reel diameter, gain and offset of the FB AIN2 can be selected in a way

that the diameter signal will be directly generated from the sensor signal.