Engine guard mount driving lights, Installation – Kuryakyn 5019 ENGINE GUARD MOUNT DRIVING LIGHTS User Manual

Page 4

PAGE

4

It is the installer’s responsibility to ensure that all of the fasteners (including

pre-assembled) are tightened before operation of the motorcycle.

Küryakyn will not provide warranty coverage on products or

components lost due to improper installation or lack of maintenance.

Periodic inspection and maintenance are required on all fasteners.

FOR UNIVERSAL WIRING ON OTHER MODELS

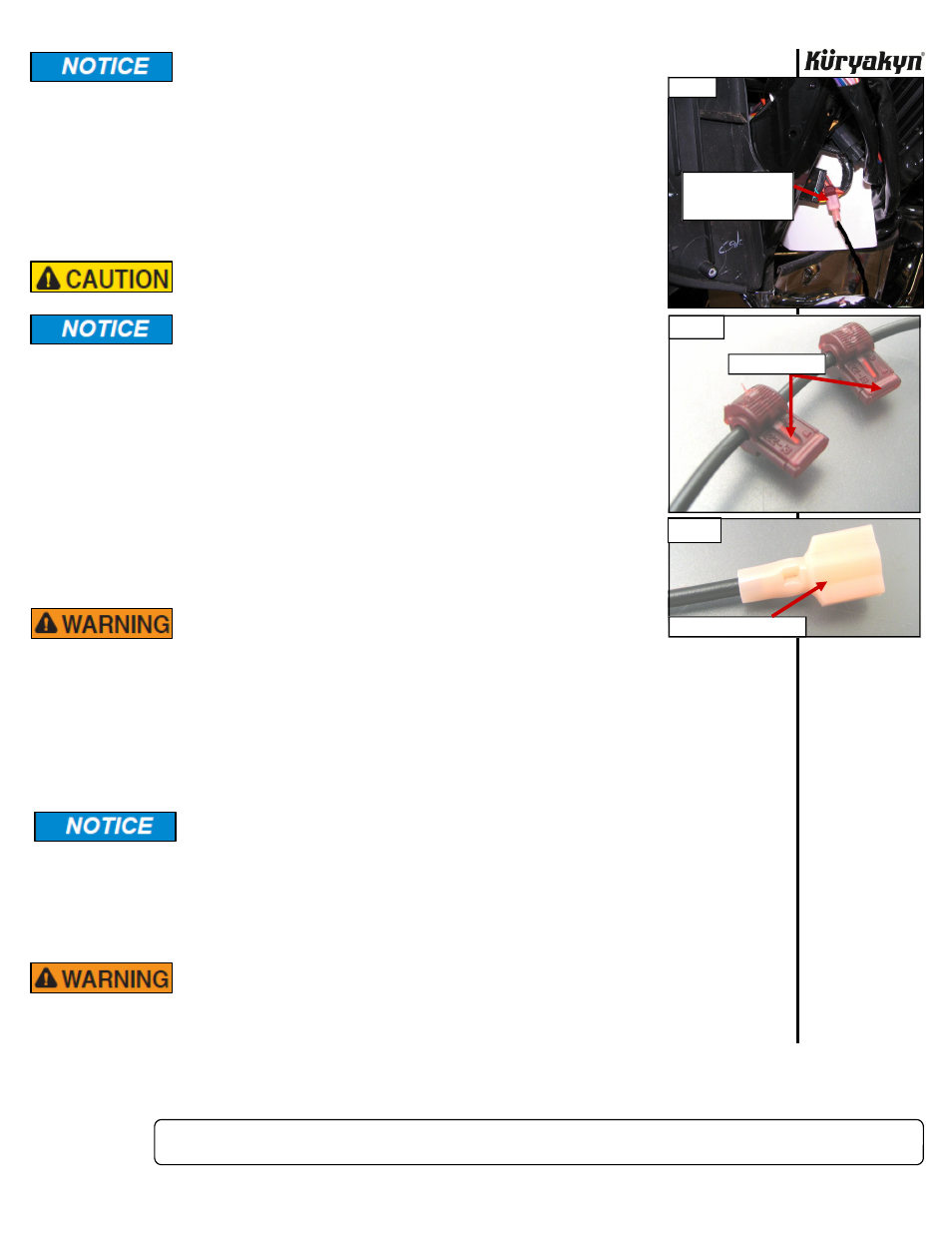

STEP 17

Using a test light or wiring schematic, with the key in the “ON” position, locate a

“keyed” (has power with the key “ON”, loses power with the key “OFF”) 12-volt

power wire to power the driving lights. Once you have located a keyed 12-volt

power source, turn the key to the “OFF” position and disconnect the battery.

Avoid potential electrical shock! Disconnect the battery

before starting this procedure.

Kuryakyn recommends the use of dielectric grease on electrical

connections.

STEP 18

Once you have located a keyed 12-volt power source, take the two female T-Tap

connectors and place them on the desired power wire. PIC 10

STEP 19

Take the black power wires and cut them to desired length, strip the ends and

place a male Spade Connector on it and crimp. PIC 11

STEP 20

Place a small amount of dielectric grease on the female T-Tap connectors and

insert the male spade connectors the female T-Tap connectors installed on the

keyed power wire. These driving lights are self-grounding so you will not need to

hook up any negative leads.

STEP 21

Once all connections are connected, turn the key to the “ON” position and check

to ensure the lights work properly.

ENSURE PROPER LIGHT OPERATION BEFORE RIDING THE

MOTORCYCLE. VISIBILITY IS A MAJOR CONCERN FOR

MOTORCYCLISTS. A LIGHTING MALFUNCTION COULD

RESULT IN DEATH OR SERIOUS INJURY.

STEP 22

If lights do not work, go over the wire connections and check all plugs to see if they are

plugged-in correctly. You may also have to use a test light again check if the spade/T-Tap

connectors are in the proper locations.

STEP 23

When you are satisfied with all the wiring, you can use the supplied cable ties and secure the

wires out of harms way.

Secure all wiring from the newly installed and/or from existing parts, away from

any moving parts, pinch points or extreme heat. Küryakyn WILL NOT issue a

warranty on any electrical component that fails due to pinched, crimped, broken,

abraded, melted or frayed wires.

STEP 24

To aim the driving lights simply loosen the bottom 3/8”-16 Nylon Chrome Nut and point to the

desired location. Retighten the 3/8”-16 Nylock Chrome Nut and repeat the same process for the

opposite

side.

IT IS THE INSTALLERS RESPONSIBILITY TO ADJUST THE NEW DRIVING

LIGHTS TO THE PATTERN RECOMMENDED IN THE SERVICE MANUAL FOR

THE HEADLIGHT LOW BEAM. FAILURE TO PROPERLY ADJUST THE LIGHT

PATTERN MAY DISTRACT ONCOMING DRIVERS RESULTING IN SERIOUS

INJURY OR DEATH.

ENGINE GUARD MOUNT DRIVING LIGHTS

INSTALLATION

PIC 10

FEMALE T-TAPS

MALE SPADE CONNECTOR

PIC 11

BLACK POWER WIRE

CONNECTED TO

SECOND ORANGE

PIC 9

-cont.-