Instruction manual – model cf2300a oil burner, Burner fuel flow – Beckett CF 2300A User Manual

Page 9

Instruction Manual – Model CF2300A Oil Burner

9

Form 6104 BCF-23-R0399

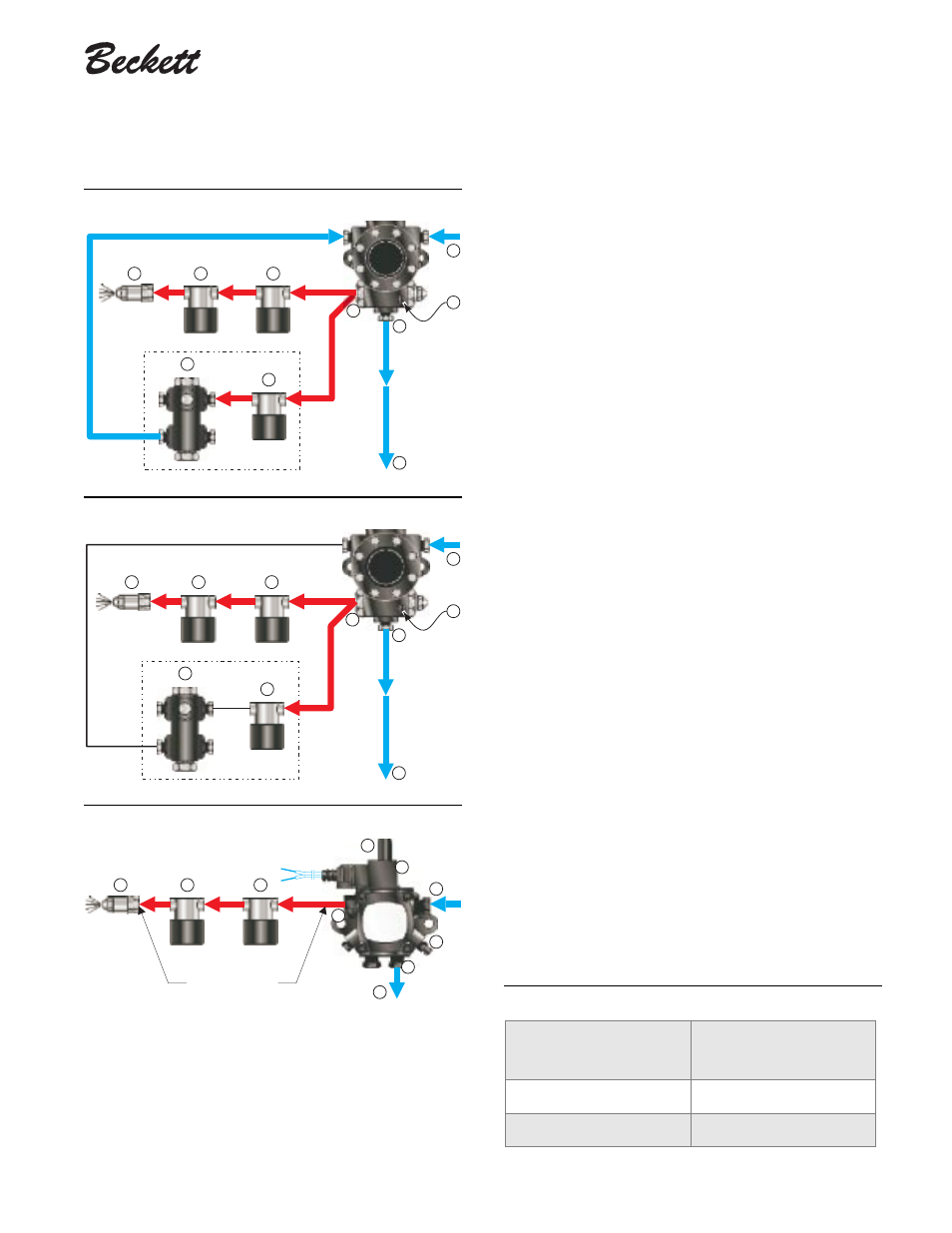

Figure 9a – Two-pipe oil flow, low fire, “

H

” pump

• Use continuous lengths of heavy-wall copper tubing,

routed under the floor where possible. Do not attach fuel

lines to the appliance or to floor joists if possible. This

reduces vibration and noise transmission problems.

• Install an oil filter sized to handle the fuel unit gearset flow

capacity (

Table 3

) for

two-pipe systems

. Size the filter

for the firing rate for

one-pipe systems

. Locate the filter

immediately adjacent to the burner fuel unit.

• Install two high-quality shutoff valves in accessible loca-

tions on the oil supply line. Locate one valve close to the

tank. Locate the other valve close to the burner, upstream

of the fuel filter.

❏ Burner fuel flow

•

One-pipe systems

– See

Figure 8

for the fuel flow paths

for high-fire and low-fire operation.

Figures 8a

and

8b

are based on type

H

fuel units, with external by-pass pres-

sure regulator. The low-fire by-pass regulation is done in-

ternally for type

B

fuel units, shown in

Figure 8c

. Oil

supply connects to one of the fuel unit Inlet ports.

•

Two-pipe systems

– See

Figure 9

for the fuel flow paths

for high-fire and low-fire operation.

Figures 9a

and

9b

are based on type

H

fuel units, with external by-pass pres-

sure regulator. The low-fire by-pass regulation is done in-

ternally for type

B

fuel units, shown in

Figure 9c

. Oil

supply connects to one of the fuel unit Inlet ports. Oil

return connects to the fuel unit Return port.

•

Low-fire/high-fire operation

– The fuel unit nozzle port

pressure is factory set at 300 psig.

• At high fire, full pressure (300 psig) is applied at the oil

nozzle, causing full input.

• At low fire, the by-pass valve (item

e

) opens. For type

H

fuel units, this allows oil to by-pass the nozzle path

through the external by-pass pressure regulator (item

f

).

For type

B

fuel units, the by-passing is done inside the

fuel unit when the by-pass valve operates.

• The by-pass oil flow is returned to the fuel unit Inlet

port for type

H

fuel units.

• This by-passing of oil reduces the oil pressure at the

nozzle (to between 125 psig and 175 psig), reducing

the input.

Figure 9c – Two-pipe oil flow with “

B

” pump

a Return port

b Nozzle port

c Oil valves

d Nozzle & adapter

e By-pass valve (“H”

pump)

f

By-pass pressure regulator

g Inlet port

h By-pass valve (“B” pump)

k Return line to oil tank

m One-pipe by-pass loop,

³⁄₈

³⁄₈

³⁄₈

³⁄₈

³⁄₈"

p Air bleed valve

Table 3 – Fuel unit gearset capacities

Figure 9b – Two-pipe oil flow, high fire, “

H

” pump

Legend

(for Figures 8a, 8b, 8c, 9a, 9b and 9c)

Fuel unit

model number

Gearset capacity

(gallons per hour)

B2TA8852

39

H4PAN-C151H

69

300 psig high fire

125 to 175 psig low fire

2323a

d

a

c

c

g

k

f

b

p

h

b

300 psig

d

300 psig

2313b

g

f

a

e

c

c

p

k

k

g

f

300 psig

2313a

d

125 psig

to

175 psig

a

e

c

c

b

p