Kds milliliter oem module, Introduction (continued), Pin-outs – KD Scientific 910 OEM Pump User Manual

Page 8: Input connections

9

KDS Milliliter OEM Module

9

Introduction (continued)

STALL DETECTION

The motor is monitored by an optical encoder to confirm the programmed movement. If the

back pressure increases due to jamming or flow restriction, then the motor may stall. Stall

detection by the encoder results in a pump shutdown.

NON-VOLATILE MEMORY

All operational settings are stored in non-volatile memory for convenience, and are used to

set the pump when first powered on.

SELECTION OF RATE AND VOLUME UNITS

Units of volume (µ or ml) and flow rate (µ/ml per min/hr) can be changed if required.

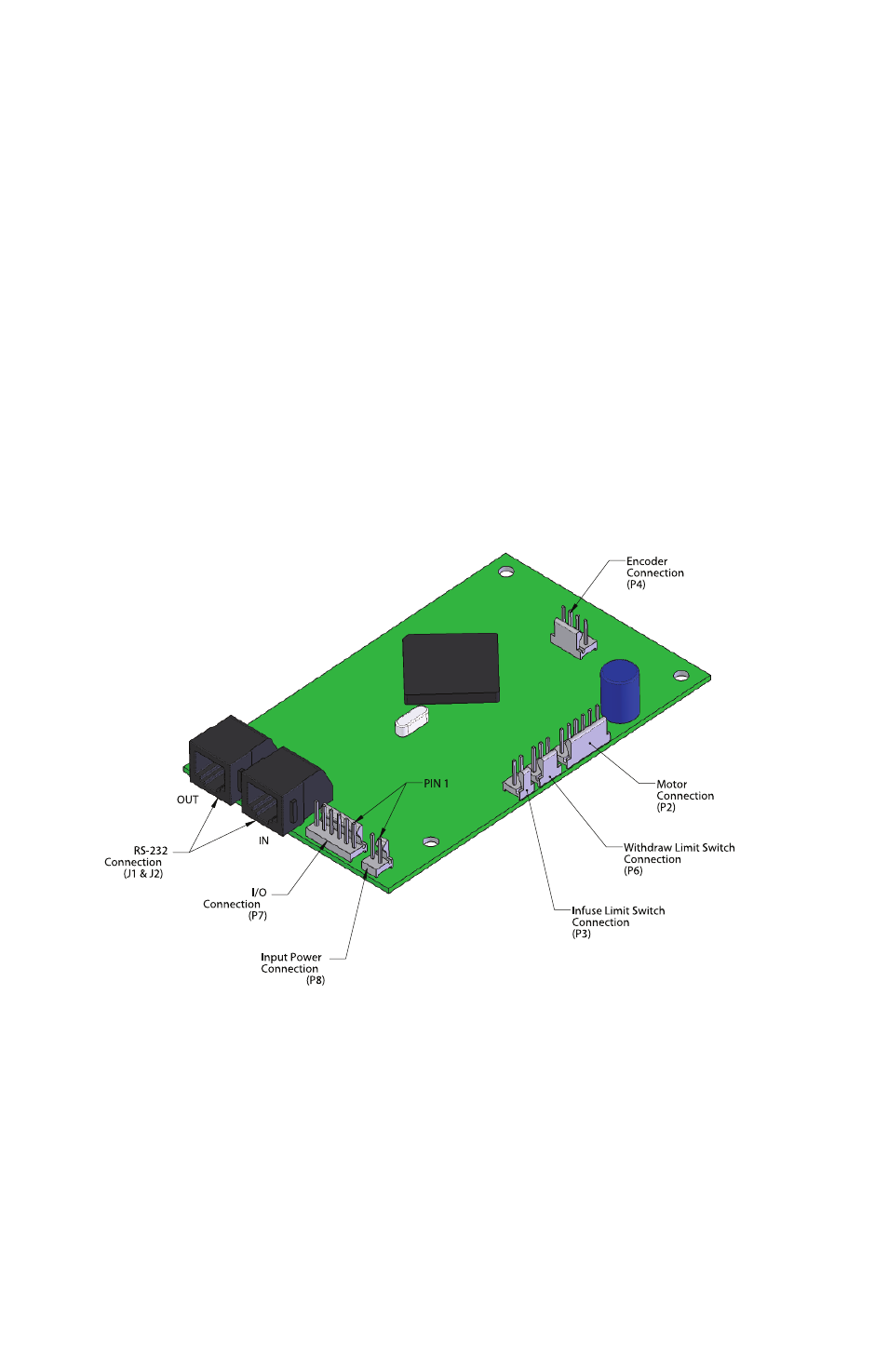

Pin-outs

Input Power

Power

P8-1

Connection

Return

P8-2

Digital I/O

Run IND

P7-1

Connection

VCC

P7-2

EXT ENABLE

P7-3

Ground

P7-4

Run/Stop

P7-5

Ground

P7-6

Input Connections