INFICON BPG400 ATM to Ultra-High Vacuum Gauge User Manual

Page 2

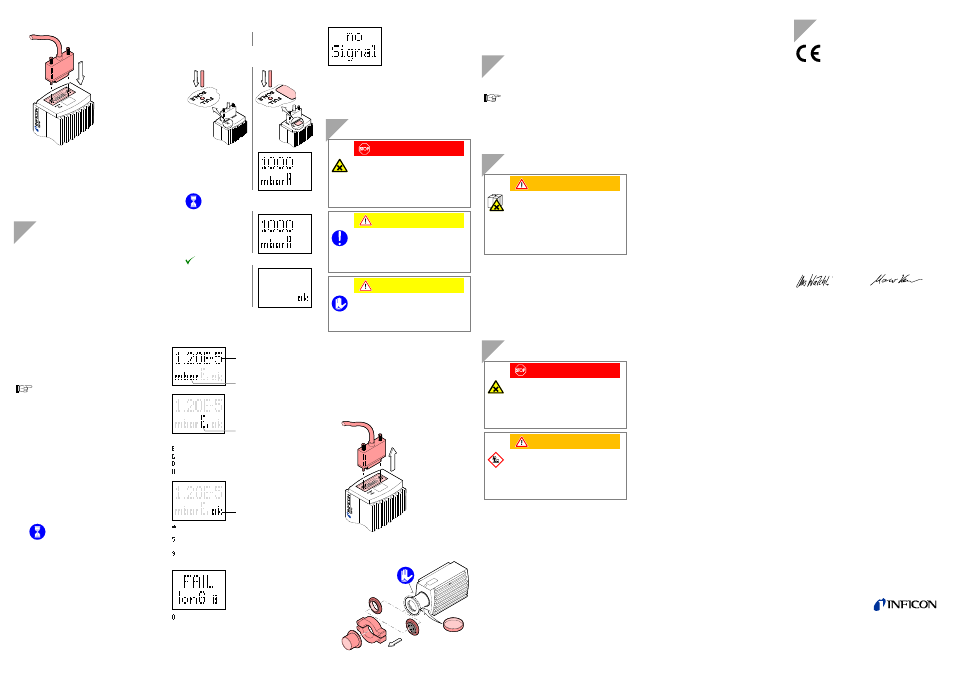

Connect the sensor cable to the gauge.

Secure the cable connector with the lock screws.

Connect the sensor cable to the controller.

Operation

When the voltage is supplied, the measuring signal is avail-

able between pins 2 (+) and 12 (–) (Relationship Measuring

Signal – Pressure

→ "Technical Data" and [1]).

BPG400-SD and -SP can also be operated via the corre-

sponding fieldbus interface (DeviceNet or Profibus

→ [1]

and [2] for further details and functions).

Allow for a stabilizing time of

≈10 minutes. Once the gauge

has been switched on, permanently leave it on irrespective of

the pressure.

Gas Type Dependence

(BPG400)

The measurement value is gas dependent. The displayed

reading applies to dry air, O

2

, CO, and N

2

. For other gases, it

has to be converted (

→ "Technical Data" and [1]).

Adjusting the Gauge

The adjustment of BPG400-SD and -SP (

→ [1]

and [2]) is slightly different from the procedure for

BPG400, which is described below.

The gauge is factory calibrated. If used under different

climatic conditions, at extreme temperatures, through aging

or contamination and after exchanging the sensor, the char-

acteristic curve can be offset and readjustment can become

necessary. Only the Pirani element can be adjusted and only

at atmosphere.

Readjustment becomes necessary if

• at atmosphere the output voltage is <10 V or the display

reading is • when venting the vacuum system, the output voltage reaches 10 V before the measured pressure has reached Activate the gauge. Operate the gauge for ≈10 minutes at atmos- pheric pressure. If the gauge was operated perature = environmental temperature). Adjusting the gauge BPG400 without display 353-500 353-502 BPG400 with display 353-501 353-503 Insert a pin ( ≈ш1.3Ч50mm) through the opening marked 5 seconds. ≈10 s Automatic adjustment Adjustment completed Display (BPG400 with part numbers 353-501 and 353-503) Pressure reading Pressure unit Function display (none) Pirani operation Emission 25 μ A Emission 5 mA Error display no error (green background illumination) Pirani sensor warning (red background illumination) Pirani sensor error (red background illumination) BA sensor error (red background illumination) Internal data connection failure Deinstallation DANGER DANGER: contaminated parts Caution Caution: vacuum component Caution Caution: dirt sensitive area Vent the vacuum system. Put the gauge out off operation. Unfasten the lock screws and unplug the sensor cable. (If you are using BPG400-SD or -SP, unfasten and → [1] and [2]). Remove the gauge from the vacuum system. Protective lid Maintenance, Troubleshooting In case of severe contamination or a malfunction, the sensor → [1]). Gauge failures due to contamination or wear and tear, as well as expendable parts (e.g. filament), are Returning the Product WARNING WARNING: forwarding contaminated products *) . *) Form under www.inficon.com Products that are not clearly declared as "free of harmful Disposal DANGER DANGER: contaminated parts WARNING WARNING: substances detrimental to the en- Separating the components After disassembling the product, separate its components • Contaminated components Contaminated components (radioactive, toxic, caustic, or • Other components Such components must be separated according to their Further Information [1] www.inficon.com Operating Manual [2] www.inficon.com Instruction Sheet EC Declaration of Conformity We, INFICON, hereby declare that the equip- Products Bayard-Alpert Pirani Gauge BPG400 Standards Harmonized and international/national standards and specifi- (EMC: generic emission standard) • EN 61000-6-3:2007 (EMC: generic immunity standard) • EN 61010-1:2010 (Safety requirements for electrical equip- ment for measurement, control and laboratory use) • EN 61326-1:2006 (EMC requirements for electrical equip- ment for measurement, control and laboratory use) Manufacturer / Signatures INFICON AG, Alte Landstraße 6, LI-9496 Balzers 11 November 2013 11 November 2013 Dr. Urs Wälchli Marco Kern LI–9496 Balzers www.inficon.com

atmosphere (Gauges with display will show the error "5" at

atmosphere (Pirani sensor warning)).

within the BA range, a cooling-down time of

≈30 minutes is to be expected (gauge tem-

Degas

1000 mbar adjustment (Pirani)

(red background illumination)

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

unplug the interface cable too (

can be replaced (

not covered by the warranty.

Contaminated products (e.g. radioactive, toxic,

caustic or microbiological hazard) can be detri-

mental to health and environment.

Products returned to INFICON should preferably

be free of harmful substances. Adhere to the

forwarding regulations of all involved countries

and forwarding companies and enclose a duly

completed declaration of contamination

substances" are decontaminated at the expense of the

customer.

Products not accompanied by a duly completed declaration of

contamination are returned to the sender at his own expense.

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

vironment

Products or parts thereof (mechanical and elec-

tric components, operating fluids etc.) can be de-

trimental to the environment.

Dispose of such substances in accordance with

the relevant local regulations.

according to the following criteria:

biological hazard etc.) must be decontaminated in accord-

ance with the relevant national regulations, separated

according to their materials, and recycled.

materials and recycled.

Bayard-Alpert Pirani Gauge BPG400, BPG400-SD,

BPG400-SP

tina03d1 (German)

tina03e1 (English)

INFICON AG, LI–9496 Balzers, Liechtenstein

Bayard-Alpert Pirani Gauge BPG400-SD, BPG400-SP

tima36d1 (German)

tima36e1 (English)

INFICON AG, LI–9496 Balzers, Liechtenstein

ment mentioned below complies with the pro-

visions of the Directive relating to electromag-

netic compatibility 2004/108/EC and the

Directive on the restriction of the use of certain

hazardous substances in electrical and

electronic equipment 2011/65/EU.

BPG400-SD

BPG400-SP

cations:

• EN 61000-6-2:2005

Managing Director

Product Manager

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

[email protected]