Maintenance, Innovative fluid power, 3 assembly – HYDAC SB 600 User Manual

Page 8

INNOVATIVE FLUID POWER

30

PN#02073469 / 07.14 / ACU1102-1326

Maintenance

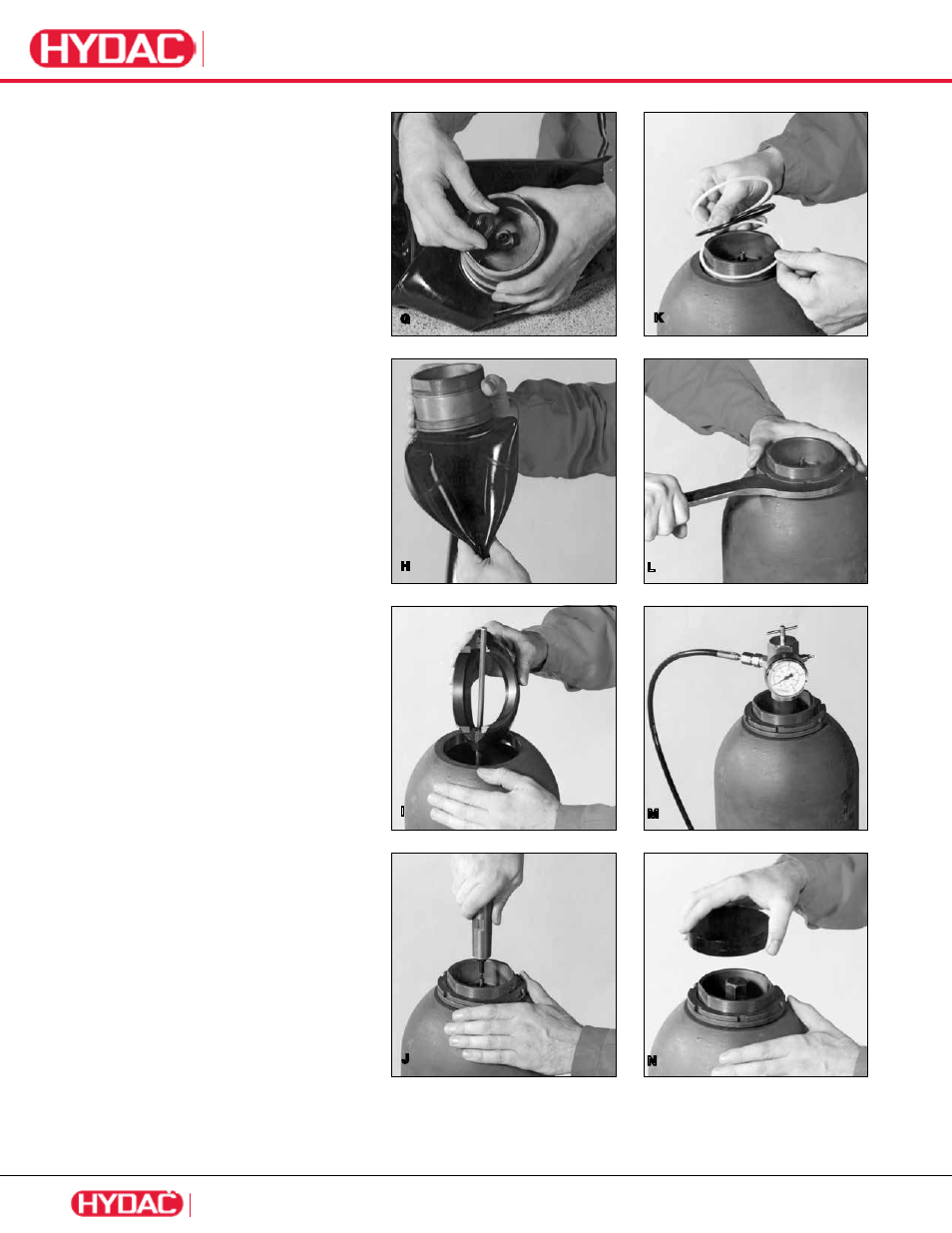

5.3 Assembly

The interior of the shell must be absolutely free of any

contamination or debris prior to assembly.

Prepare bladder for installation by removing

valve seal

cap

(item 5)

, and

gas valve core

(item 3)

. Purge all

residual air.

Lubricate interior of shell and exterior of bladder

with appropriate filtered fluid, using a fluid volume of

approximately 10% of total accumulator volume.

(Do not use water, it is not a lubricant)

.

Different bladder compounds require different lubricants.

G Attach gas port adapter

(item 22)

to bladder with gas

valve protruding through adapter opening. Loosely

screw

bladder stem lock nut

(item 4)

onto gas valve to

keep gas port and bladder connected.

H Fold bladder

(item 2)

in half lengthwise and insert

through gas side opening. Make sure bladder is

stretched and not twisted when being inserted. Thread

pull rod onto gas valve to position gas port adapter.

I Place the anti-extrusion ring

(item 24)

over the pull rod

with the steel parts facing upward. Fold

anti-extrusion

ring

(item 24)

in half and insert into shell. To do this, push

gas port adapter further into shell and then pull it back

through anti-extrusion ring. Slide

gas port lock nut

(item

31)

over and pull rod with beveled surface facing away

from shell; loosely thread the gas port lock nut onto the

gas port adapter. Remove pull rod from gas valve.

J Insert gas valve core

(item 3)

and torque to 0.5 Nm

(0.4 lb-ft). Precharge bladder with 10 to 15 psi of dry

nitrogen to hold

gas port adapter

(item 22)

in place while

completing assembly.

K Remove gas port lock nut

(item 31)

. Insert

flat ring

(item

28)

into space between gas port and shell. If it does

not slide on properly, re-center gas port in opening.

Next, insert

O-ring

(item 29)

by pressing with a blunt

flathead screwdriver

(with rounded edges)

at 90° intervals.

Carefully, level O-ring onto seat. Insert

back-up ring

(item 30)

over O-ring with grooved surface toward O-ring.

L Install spacer ring

(item 17)

. Thread on

gas port lock

nut

(item 31)

with beveled surface facing away from shell

and torque with spanner wrench*. Torque*

bladder stem

lock nut

(item 4)

.

M Attach HYDAC Charging and Gauging Unit

(FPK

with adapter FPK/SB)

and apply proper gas precharge

pressure

(refer to HYDAC Charging and Gauging brochure

#02068202)

. Check

bladder stem lock nut

(item 4)

torque

2)

.

N Screw on

valve seal cap

(item 5)

and torque*. Replace

valve protection cap

(item 6) (if applicable)

.

*refer to torque table in section 4.1.

G

M

I

L

H

K

J

N