Warning – Gast 22D Series User Manual

Page 5

Gast will NOT guarantee field-rebuilt product

performance. For performance guarantee, the product

must be returned to a Gast Authorized Service Facility.

Service Kit contents vary. Most contain gasket and filter

parts.

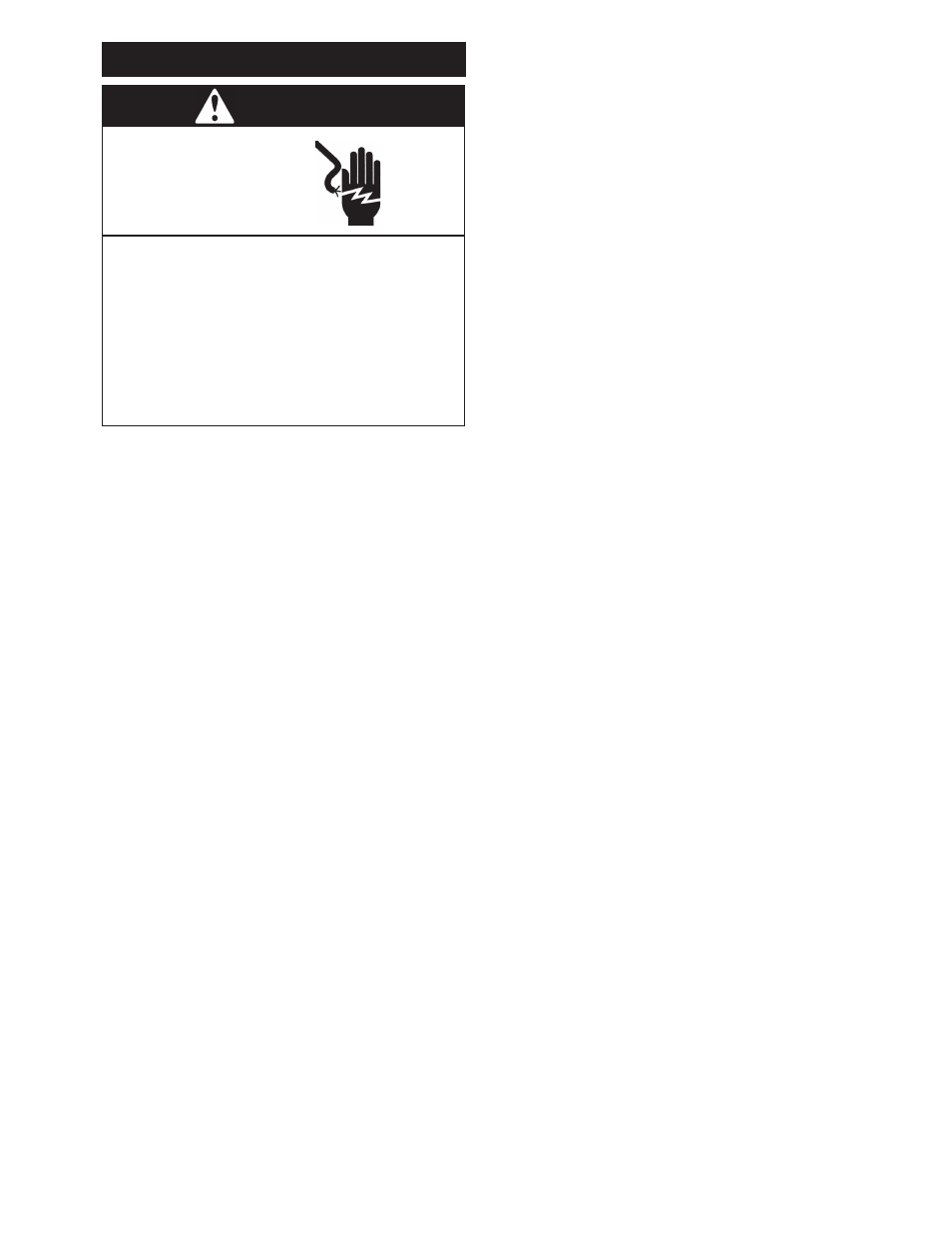

SERVICE KIT INSTALLATION

Ꮨ

Disconnect electrical power supply cord before

installing Service Kit.

If product is hard wired into system, disconnect

electrical power at the circuit breaker or fuse box

before installing Service Kit.

Vent all air lines to release pressure or vacuum.

Failure to follow these instructions can result in

death, fire or electrical shock.

WARNING

Electrical Shock Hazard

7. Clean head and valve plate using water-based

solvents.

8. Reattach exhaust valve and valve retainer to valve

plate. Note location of “X” stamped on valve retainer.

This must be orientated as shown or valve may break

prematurely.

9. Torque pan head screw to 12 in.-lbs. (once assembled,

make sure valve remains over exhaust port when

closed).

10. Reinstall gasket and valve plate into head. Valve plate

and head are designed so that valve plate can be

installed in one orientation only.

11. Install four flat head screws and torque to 12 in-lbs.

12. Reinstall intake valve and its retainer. Note location of

“X” stamped on valve retainer. This must be orientated

as shown or valve may break prematurely.

13. Reinstall pan head screw and torque to 12 in-lbs.

14. Tighten head in place using four head screws and

torque to 25-27 in-lbs.

Check that all external accessories such as relief valves

and gauges are not damaged before

re-operating product.

If pump still does not produce proper vacuum or pressure,

send unit to a Gast Authorized Service Facility for repair.

Follow these steps to replace diaphragm:

1. Label ports noting direction of arrows so you can orient

pump head correctly during reinstallation.

2. Remove four corner head screws.

3. Remove head assembly.

NOTE:Head assembly is inseparable. Do not attempt to

disassemble.

4. Remove four flat head screws on retainer plate.

5. Remove retainer plate and diaphragm.

6. Clean pump head and retainer using water base solvents.

NOTE:

Do not use petroleum-base compounds, acids, caustics,

or chlorinated solvents to clean or lubricate any parts, It

will reduce service life of pump.

7. Re-attach retainer plate and diaphragm to rod with four flat

head screws. Torque screw to 20 in-lbs.

8. Make certain diaphragm is in recessed area of bracket and

re-install head assembly in proper orientation, twisting it

slightly back and forth to seat diaphragm in head and bracket.

9. Tighten head in place using four head screws and torque to

25-27 in-lbs.

Valve Replacement

Follow these steps to replace valves:

1. Label ports noting direction of arrows so you can orient

pump head correctly during reinstallation.

2. Remove four corner head screws.

3. Remove head assembly.

4. Remove valve plate by removing four flathead screws

around perimeter and pan head screw in center (this screw

also retains intake valve).

5. Remove intake valve, its retainer, valve plate and gasket.

6. Remove pan head screw from other side of valve plate (this

screw retains exhaust valve).