Warning – Gast 55R Series User Manual

Page 5

Gast will NOT guarantee field-rebuilt product

performance. For performance guarantee, the

product must be returned to a Gast Authorized

Service Facility.

Service Kit contents vary. Most contain gasket and filter

parts.

SERVICE KIT INSTALLATION

Ꮨ

Disconnect electrical power supply cord before

installing Service Kit.

If product is hard wired into system, disconnect

electrical power at the circuit breaker or fuse box

before installing Service Kit.

Vent all air lines to release pressure or vacuum.

Failure to follow these instructions can result in

death, fire or electrical shock.

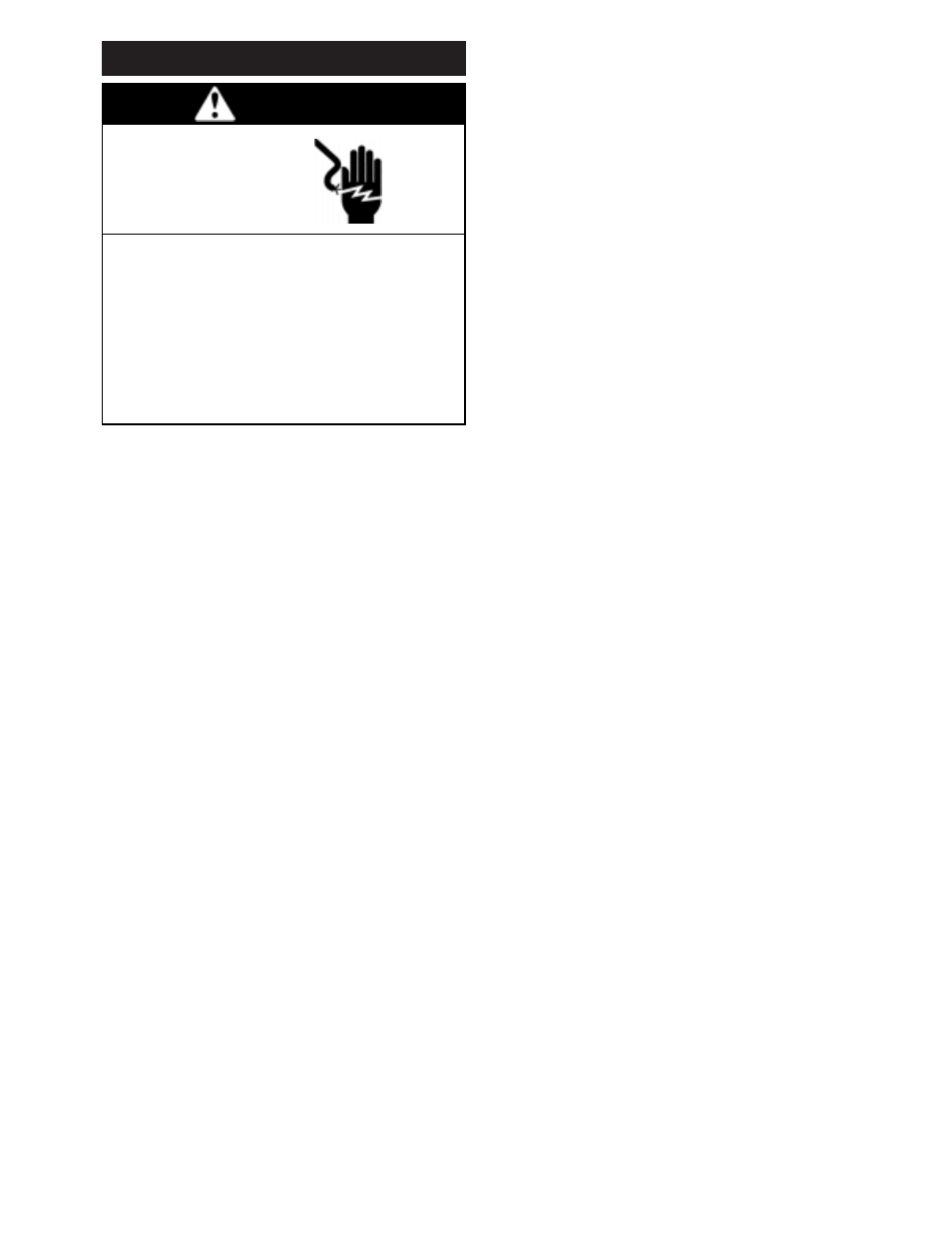

WARNING

Electrical Shock Hazard

Compressor Head Reassembly:

NOTE: The kit contains two different cylinder/cup

assemblies. The assemblies can be identified by the

direction of the piston cup lip (see Fig. 2) The pressure

cylinder piston cup is positioned with the lip toward

the head.

10. Locate the pump mounting pad nearest to the motor.

Install the new cylinder/cup assembly into the pump

mounting pad and over the piston.

NOTE: The pressure cylinder/cup assembly must be

installed nearest to the motor for long shaft bearing

life.

11. Place the retainer over the piston cup. Reinstall the

cleaned phillips head screw you set aside earlier,

using Loctite 222 or equivalent. Torque the screw to

26-30 lb-in.

12. Install a new O-ring in the groove in the pressure

cylinder. Install a new pump head gasket in the

groove in the pump head ( see Fig. 3).

13. Place the valve plate on the pump head so that the

recessed intake valve is exposed (faces away from

the pump head) as shown. Be sure the valve plate is

oriented so the recessed intake valve coincides

with the intake chamber.

14. Using the four phillips head screws you set aside

during disassembly, reinstall the pump head and valve

plate on the mounting pad nearest to the pump.

Position the pump head and valve plate according to

your labeling. Torque the screws to 26-30 lb.-in.

Vacuum Pump Head Reassembly:

NOTE: The kit contains two different cylinder/cup

assemblies. The assemblies can be identified by the

direction of the piston cup lip (see Fig. 2). The

vacuum cylinder piston cup is positioned with the lip

inward, away from the head.

15. Locate the pump mounting pad farthest from the

motor. Install the new cylinder/cup assembly into the

pump mounting pad and over the piston.

NOTE: The vacuum cylinder/cup assembly must be

installed farthest from the motor for long shaft

bearing life.

16. Place the retainer over the piston cup. Reinstall the

cleaned phillips head screw you set aside earlier,

using Loctite 222 or equivalent. Torque the screw to

26-30 lb-in.

17. Install a new O-ring in the groove in the vacuum

cylinder. Install a new pump head gasket in the

groove in the pump head (see Fig. 3).

18. Place the valve plate on the pump head so that the

recessed intake valve is exposed (faces away from

pump head), as shown. Be sure the valve plate is

oriented so that the recessed intake valve coincides

with the intake chamber, as shown. Refer to the flow

arrows stamped on the pump head.

19. Using the four phillips head screws you set aside

during disassembly, reinstall the pump head and valve

plate on the mounting pad farthest from the pump.

Position the pump head and valve plate according to

your labeling. Torque the screws to 26-30 lb-in.

Check that all external accessories such as relief

valves and gauges are not damaged before

re-operating product.

If pump still does not produce proper vacuum or pressure,

send unit to a Gast Authorized Service Facility for repair.

1. Disconnect electrical power to pump.

2. Disconnect air supply and vent all air lines to

release pressure or vacuum.

Pump Head Assembly:

3. Label the head so you can reposition it correctly during

reinstallation. Remove the four phillips head screws at the

corners of the pump head, then remove the head and valve

plate. Set the screws aside for later reassembly.

4. Use needle nose pliers to pull the rubber valves from the

valve plate, and discard them.

5. Remove the phillips head screw at the center of the piston

cup retainer ( the “head” of the piston) and remove the

retainer. Clean the screw and set it aside for later

reassembly.

6. Remove the cylinder and piston cup as a unit from the body

of the pump.

Valve Installation

7. Clean the valve holes in the valve plate. Do not make any

scratches or burrs in the edges of the valve holes.

8. Install the new valves from the opposite sides of the valve

plate ( see Fig. 1). Insert the valve stem through the center

hole of the group of small holes at each valve location.

With needle nose pliers, gently stretch the valve stem to

pull the ball on the stem through the other side of the valve

plate.

9. Use diagonal cutters to trim off the excess valve stem above

the ball as shown.