Gast 2567 Series Oilless Vacuum Pumps and Compressors User Manual

Page 6

10. Release shaft and rotate rotor to next position.

Check rotor lobe. Set each clearance to the

tightest setting. Repeat until all lobes have been

checked.

11. Remove from fixture and tighten remaining screws.

12. Either leave dowel pins out or drill new dowel pin

holes and use new dowel pins.

Do Not re-use old

dowel pins.

Check that all external accessories such as relief valves

and gauges are attached to cover and are not

damaged before re-operating product.

If pump still does not produce proper vacuum or

pressure, send unit to a Gast Authorized Service

Facility for repair.

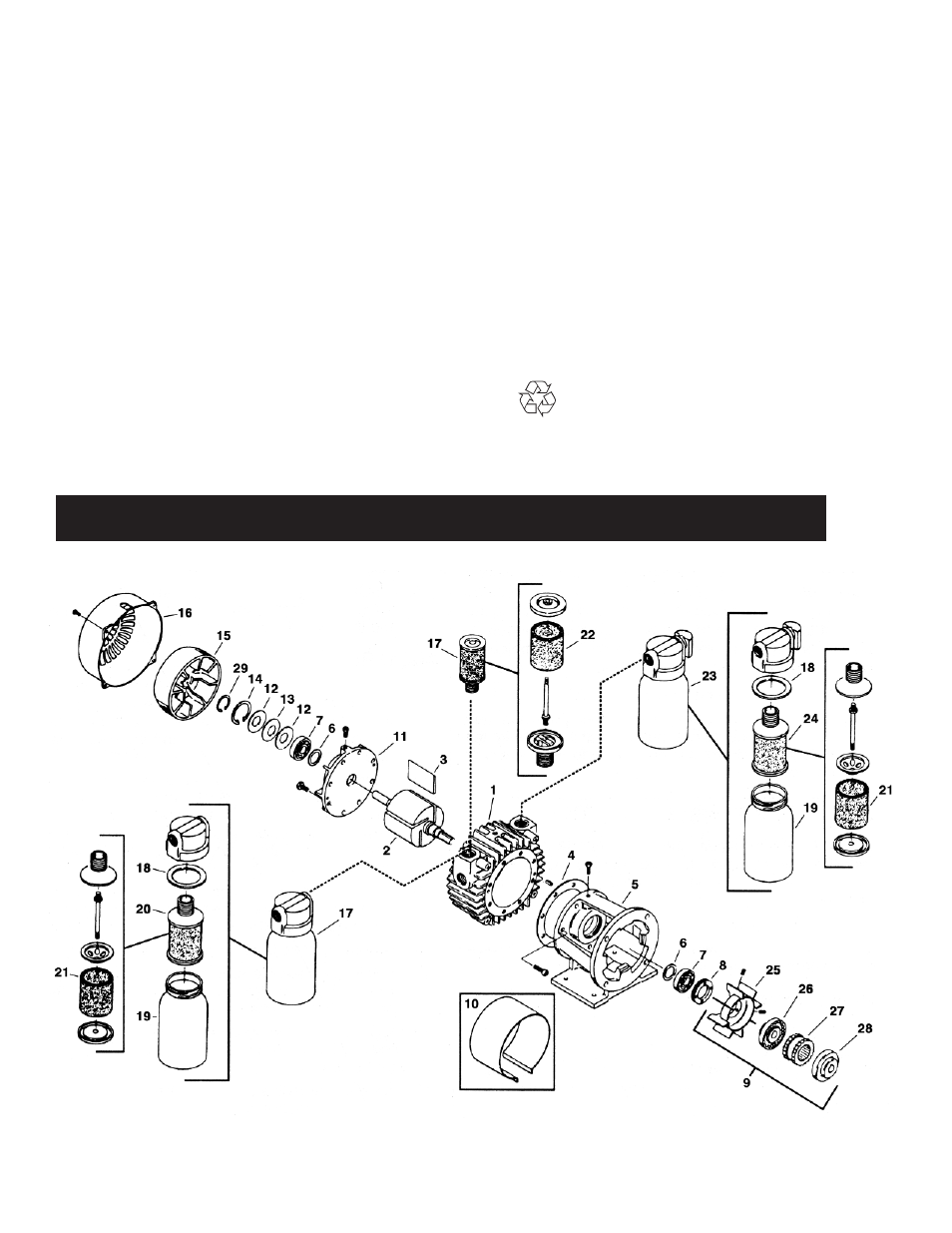

EXPLODED PRODUCT VIEW, PARTS & ORDERING INFORMATION

6

For the following exploded view, please reference Series and Model parts chart on facing page.

Disposal

(Please note current regulations)

Parts of the rotary vane pumps and

compressors, shafts, iron or aluminum castings,

plastic or glass parts or bearings, may be

recycled as scrap materials.

Replacing New Body or Rotor

1.

Use a micrometer to read the rotor length and

body thickness. Subtract rotor length from body

thickness. Check with Factory for clearances.

2.

For desired rotation, the inlet port needs to be to

the left of the body for counter-clockwise rotation

or to the right for clockwise rotation.

3.

If gasket is needed, place one or more gaskets on

body face.

4.

Place rotor through body bore.

5.

Place drive end plate on body gasket.

6.

Install all screws and hand tighten.

7.

Place motor with drive down in fixture and apply

pressure to hold against drive end plate.

8.

Place a .003” shim between rotor and body bore.

Tap body toward or away from rotor until shim is

snug and resists being moved.

9.

Tighten bolts at the 9:00 and 3:00 o’clock positions.