115 volt installation – Flint & Walling Booster Pump Flow Protector Instructions User Manual

Page 3

3

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

WIRING PROCEDURES FOR 115V CONTROL

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. If the motor wiring must be changed to conform to

your specific voltage requirements, consult documentation

provided with the pump motor for correct procedure.

1. Install and maintain your pump in accordance with your

local electrical code and all other codes and ordinances

that apply. Consult your local building inspector for local

code information.

2. Plug the 115V power cord from the electronic flow

protector box into a properly grounded 115V receptacle.

3. Plug a properly sized and grounded power cord from the

pump motor into the “piggy back” outlet of the power

cord of the electronic flow protector.

IMPORTANT: Check local and/or United States National

Electric Codes for proper grounding information.

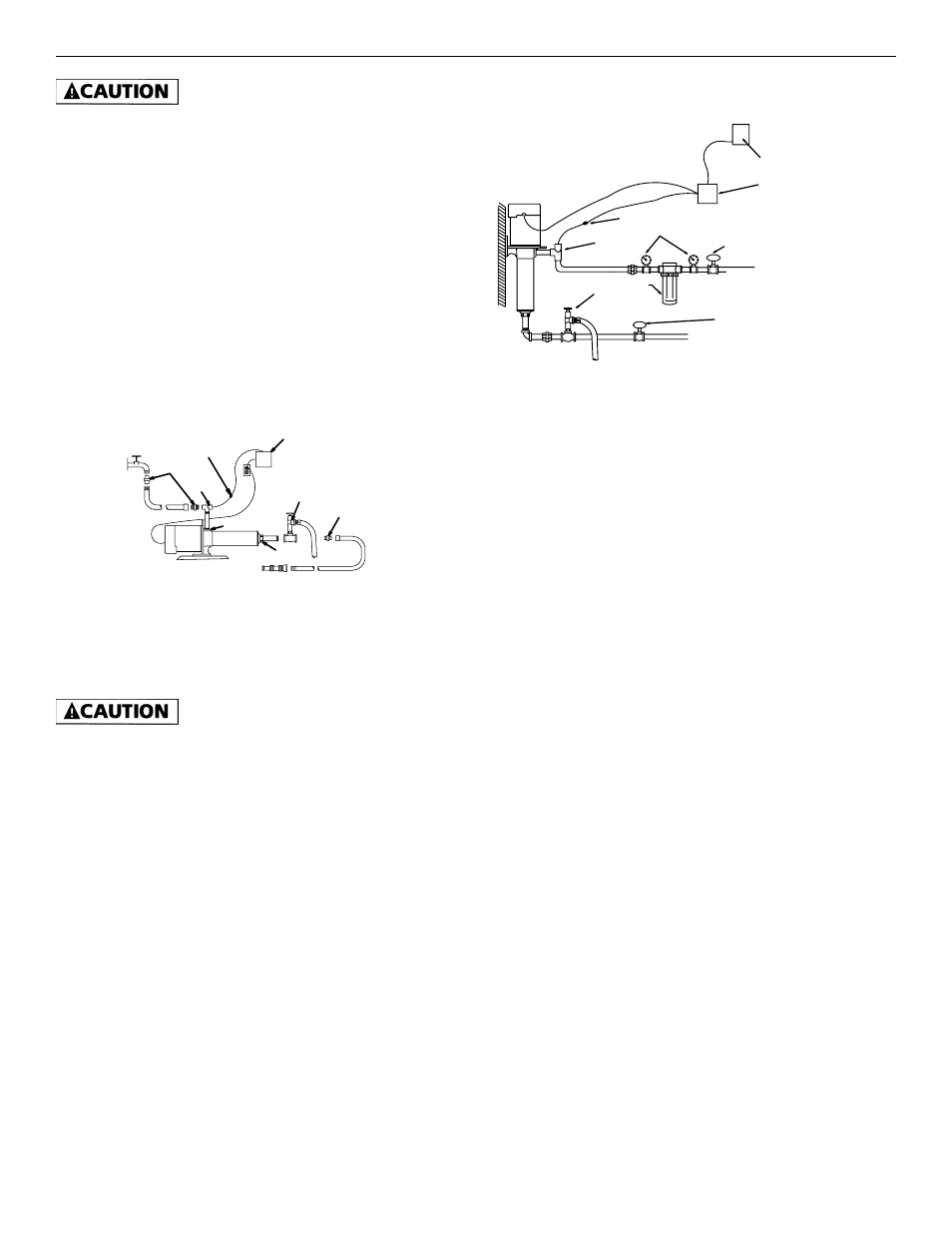

HOSE

ADAPTER

HIGH PRESSURE

REINFORCED HOSE

HIGH PRESSURE

REINFORCED HOSE

WALL HYDRANT

INLET

PRESSURE RELIEF

VALVE

HOSE ADAPTER

OUTLET

SPRAY

NOZZLE

CONNECTORS

ELECTRONIC FLOW PROTECTOR

FLOW

SENSOR

TO DRAIN

IL0630

F&W

115 VOLT INSTALLATION

115 VOLT

Figure 3

WIRING PROCEDURES FOR 230V CONTROL

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. If the motor wiring must be changed to conform to

your specific voltage requirements, consult documentation

provided with the pump motor for correct procedure.

1. Feed the lead wire labeled Output (Motor) from the

electronic flow protector to the terminal block of the

motor.

2. Connect the green ground wire first to the grounding

terminal provided on the motor frame. Ground connection

MUST be made to this terminal. Do not connect motor to

electrical power supply until unit is permanently grounded;

otherwise serious or fatal electric shock hazard may be

caused.

3. Attach the black and white wires to the power

supply terminals or wires of the pump motor, consult

documentation provided with the pump motor for correct

location and wiring procedures.

4. Feed the lead wire labeled Input Power from the electronic

flow protector to your 230V electrical power supply.

5. Connect the green ground wire first to the grounding

terminal within the electrical supply box as specified by

local or United States National Electrical code. Do not

ground to a gas supply line. Do not connect the electronic

flow protector to electrical power supply until unit is

permanently grounded; otherwise serious or fatal electric

shock hazard may be caused.

6. Connected black and white wires as specified by local or

United States National Electrical code to the disconnected

supply voltage.

PRESSURE GAUGE

FUSE DISCONNECT OR BREAKER BOX

ELECTRONIC FLOW PROTECTOR

GATE/BALL VALVE

FROM

WATER SOURCE

GATE/BALL VALVE

(NORMALLY OPEN)

TO DRAIN

LINE FILTER

PRESSURE

RELIEF VALVE

CONNECTORS

FLOW SENSOR

F&W

230 VOLT

230 VOLT INSTALLATION

IL0628

Figure 4

OPERATION:

Priming of the pump is automatic when pump is connected to

a positive supply of water such as a hydrant or city main.

1. Disconnect power to the electronic flow protector and

pump. (Unplug 115V model, turn off disconnect to 230V

model.)

2. Open values and/or nozzle on suction and discharge side of

the pump.

3. To relieve trapped air, allow water supply to run a

minimum of 30 seconds before starting the pump.

4. Connect power to the electronic flow protector and pump.

(Plug in the 115V model, turn on disconnect to 230V

model.)

5. As long as there is at least 1.0 GPM of water flowing

through the pump, the pump will continue to run. If the

water supply or discharge valve and/or nozzle is closed,

which causes less that 1.0 GPM of water to flow through

the pump, the electronic flow protector will turn off the

pump in 20 to 30 seconds. Once the flow has returned to

at least 1.0 GPM, the flow protector will turn the pump

back on.