Flex retrofit drain pvc coated flange model – Flex Retrofit Drain PVC Coated Flange User Manual

Page 2

Flex Retrofit Drain

PVC Coated Flange Model

FOR USE WITH

Flex PVC membrane roof systems.

JOB PREPARATION

The existing leader pipe shall be cleaned

of excess bitumen build-up, dirt and debris.

Remove the clamping ring assembly and bolts

from the existing drain and discard. If required,

comply with roof manufacturer’s directions for

additional cleaning or detailing.

STEP 1

Important – The aluminum activation cone

may have settled into the backflow seal during

shipping which may partially activate the seal.

To deactivate the seal, simply push down on the

top of the two backflow bolts.

Note: The top

of the tapered metal cone should remain inside

the bottom of the urethane seal. Do not fully

disengage cone from urethane seal.

STEP 2

Install the Flex PVC membrane over the existing

drain location. Cut a hole in the membrane the

same diameter as existing leader pipe. The

hole should be centered over the existing pipe

opening and accommodate the O.D. of RAC

drain pipe to be installed.

STEP 3

Lower the RAC PVC Drain Assembly into the

existing drain leader pipe until the underside

of the drain flange sits flat on the roof. Using

the pre-punched holes in the perimeter of the

flange, secure the drain flange to the substrate

with appropriate fasteners.

STEP 4

Hand tighten the

7

/

16

-in. bolts on the backflow

rods to activate the seal.

Alternate tightening

between the bolts for an even seal. Rods should

be snug when fully activated. Do not over tighten.

STEP 5

Clean membrane and drain flange surfaces. Hot

air weld the flashing membrane to the coated

drain flange and to the surrounding field sheet.

Flashing membrane should extend onto field

sheet a minimum of 4 inches.

STEP 6

Place the drain strainer over the two strainer

securement brackets, lining the brackets up

with the two 5-in. long slots in the top of the

strainer. Install stainless steel bolts and washers

(provided) into the securement brackets with a

7

/

16

-in. wrench. Tighten nuts snugly into position.

For technical assistance contact

Flex at 800.969.0108 or fax 610.916.9501.

I N S T A l l A T I O N P R O C E D U R E

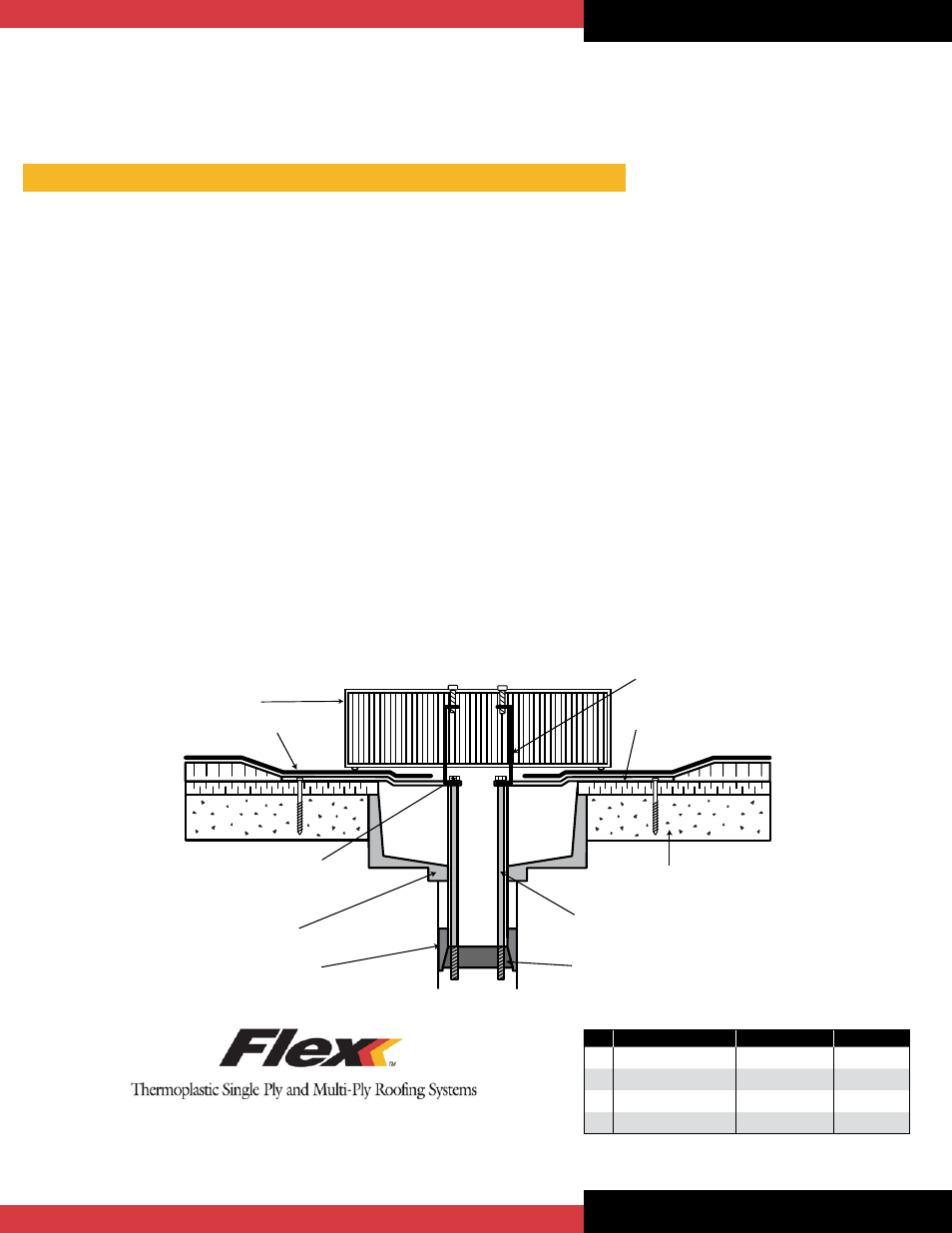

Drain Strainer

Strainer Securement Brackets

Roof Decking

Roofing System

Cast Aluminum Activation Cone

Stainless Steel Rods for

Backflow Seal Activation

Compressible Urethane

Backflow Seal

7

/

16

" Stainless Steel Bolt

Heads for Activation of

the Backflow Seal

Existing Drain Bowl

PVC Coated Pre-Punched

Drain Flange

SEAl EXPANSION CAPACITY

SIzE

O.D. OF PRE-EXPANDED SEAL FIT INTO MIN. PIPE I.D. FULLY EXPANDED

3"

2.75"

2.77"

3.12"

4"

3.85"

3.87"

4.20"

5"

4.81"

4.83"

5.12"

6"

5.85"

5.87"

6.30"

O.D. = Outside Diameter I.D. = Inside Diameter

Due to manufacturing variances and job site inconsistencies, these figures

are guidelines and are not guaranteed.

800-969-0108 • 610-916-9501 (Fax)

2670 Leiscz’s Bridge Road, Suite 400, Leesport, PA 19533

e-mail: [email protected] • www.flexroofingsystems.com

As with all building materials, it is the responsibility of the installer to review its usage with a design professional to

confirm safety, compatibility and acceptance with the Flex Membrane roof system as well as local building codes.