Operating instructions read heads/actuators cem-a – EUCHNER CEM-A-xxx User Manual

Page 5

Operating Instructions Read Heads/Actuators CEM-A-...

Correct use

Series CEM-A read heads are operated in combi-

nation with an evaluation unit in the system fam-

ily CES-A-...B or CES-AZ-...B. In this combination

the read head CEM-A is an interlock device with

electromagnetic guard locking without guard lock

monitoring. The combination is not allowed to be

used as guard locking for the protection of personnel

in accordance with EN 1088.

In combination with a separating safety guard and

the machine control, this safety component prevents

dangerous machine movements from occurring

while the safety guard is open.

A stop command is triggered if the safety guard is

opened during the dangerous machine function.

For the control system, this means that

f

starting commands which cause hazardous situ-

ations must become active only when the safety

guard is in the protective position.

Before safety components are used, a risk as-

sessment must be performed on the machine in

accordance with

f

EN ISO 13849-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design, Annex B

f

EN ISO 14121, Safety of machinery. Risk assess-

ment. Principles.

f

IEC 62061, Safety of machinery. Functional safety

of safety-related electrical, electronic and program-

mable electronic control systems.

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

f

EN ISO 13849-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design

f

EN 1088, Safety of machinery. Interlocking

devices associated with guards. Principles for

design and selection

f

EN 60204-1, Safety of machinery. Electrical equip-

ment of machines. General requirements.

The read head must be used only in conjunction with

the designated CEM actuator from EUCHNER. On

the use of different actuators or other connection

components, EUCHNER provides no warranty for

safe function.

The series CEM read head must be operated only

in combination with evaluation units in the system

family CES-A-...B or CES-AZ-...B. Please check this

in the "Combination options" table in the manual of

the evaluation unit used.

Important:

f

The user is responsible for the integration of the

device in a safe overall system. For this purpose,

the overall system must be validated, e.g. in ac-

cordance with EN ISO 13849-2.

f

Correct use requires observing the permissible

operating parameters (see Technical data).

f

If a product data sheet is included with the

product, the information on the data sheet ap-

plies in case of discrepancies with the operating

instructions.

f

The PL that can be achieved depends on the

evaluation unit used.

Notes for devices with ATEX rating

f

Read heads with ATEX rating must be used only

in combination with evaluation units and actuators

that possess at least the equivalent ATEX rating.

f

Observe the safety notes in the system manual of

the evaluation unit used.

Exclusion of liability and warranty

In case of failure to comply with the conditions for

correct use stated above, or if the safety instruc-

tions are not followed, or if any servicing is not

performed as required, liability will be excluded and

the warranty void.

Safety precautions

Safety components fulfill personal protection func-

tions. Incorrect installation or tampering can lead to

fatal injuries to personnel.

Check the safe function of the safety guard par-

ticularly

f

after any setup work

f

after the replacement of a system component

f

after an extended period without use

f

after every fault

Independent of these checks, the safe function of the

safety guard should be checked at suitable intervals

as part of the maintenance schedule.

Fatal injury due to incorrect connection or incor-

rect use.

f

Safety switches must not be bypassed (bridg-

ing of contacts), turned away, removed or

otherwise rendered ineffective. On this topic

pay attention in particular to the measures for

reducing the possibility of bypassing from EN

1088:1995+A2:2008, Section 5.7.

The device may be installed and put into opera-

tion only by authorized experts

f

who are familiar with the correct handling of

safety components

f

who are familiar with the applicable EMC

regulations

f

who are familiar with the applicable regula-

tions on health and safety and accident

prevention

f

who have read and understood the operating

instructions and the system manual.

The switching operation must only be triggered

by actuators specifically provided for this pur-

pose (see ordering table) which are positively

connected to the safety guard.

Function

The CEM read head behaves like a CES read head

(see manual of the evaluation unit used). As soon as

the actuator reaches the operating distance of the

read head, a signal is sent to the evaluation unit.

CEM read heads additionally feature a solenoid to

produce the locking force. The guard locking is not

monitored.

f

Version with remanence

The guard locking is activated as soon as the control

voltage U

CM

is present (open-circuit current principle).

The solenoid retains a slight residual magnetism

after it is switched off. This decreases over time.

This process is faster when the safety door is open

than when it is closed.

f

Version without remanence

The guard locking is activated when, in addition

to operating voltage U

B

, the control voltage U

CM

is

present (open-circuit current principle).

In particular during metal machining, the residual

magnetism (remanence) in the guard locking solenoid

can cause problems. In the open state, metal chips

may be drawn to the contact area. The next time the

guard is closed, there will be a gap between the ac-

tuator and read head that will limit the locking force.

To avoid this effect there are read heads without

remanence. These read heads are demagnetized

when the mounting magnet is switched off. For

this purpose the operating voltage U

B

must always

be applied.

f

LED

CEM devices with a locking force of 500 N feature

an integrated LED on plug connector X1.

An external LED can be connected to plug connector

X2 on devices with a locking force of 1,000 N.

The LED illuminates when the solenoid is energized.

Mounting

The read head must not be opened.

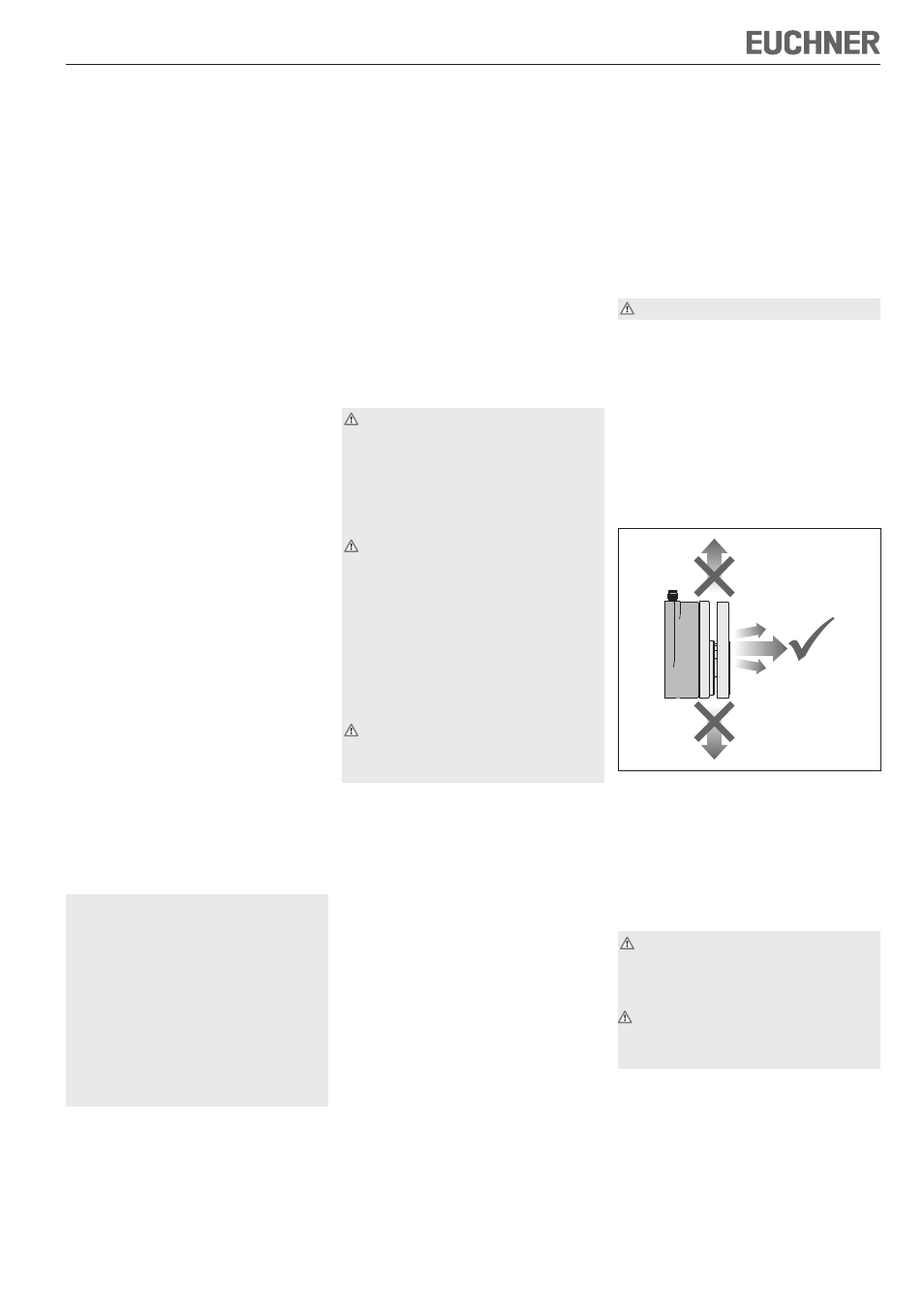

Install read head and actuator so that

f

when the safety door is opened, the actuator is

moved away from the read head toward the front

(see Figure 1 Approach direction).

f

access to it is difficult for operating personnel

when the safety guard is open

f

it is possible to check and replace the read

head.

f

Mount the read head positively.

f

Permanently connect the actuator to the safety

guard so that it cannot be detached, e.g. using

the enclosed non-removable screws, rivets or

welding.

Read head

Actuator

± 4°

Figure 1: Approach direction

Protection against environmental effects

Dirt on the surfaces of the read head and actuator

can reduce the adhesive force and the locking force.

Clean the surfaces at regular intervals.

Cover the read head, the actuator and the rating

plate during painting work!

Electrical connection

All the electrical connections must either be

isolated from the mains supply by a safety trans-

former according to IEC EN 61558-2-6 with limited

output voltage in the event of a fault, or by other

equivalent isolation measures.

If a common power supply is used, all the induc-

tive and capacitive loads (e.g. contactors) con-

nected to the power supply must be connected

to appropriate interference suppression units.

f

For terminal assignment see Figure 4.

f

For detailed information see the system manual

for the evaluation unit used.