Enerpac VE32, VE32D User Manual

Page 3

6. Shift the valve to the neutral position, allowing the

system pressure to return to 0 psi.

7. Recheck the final pressure setting by shifting the

valve and pressurizing the system.

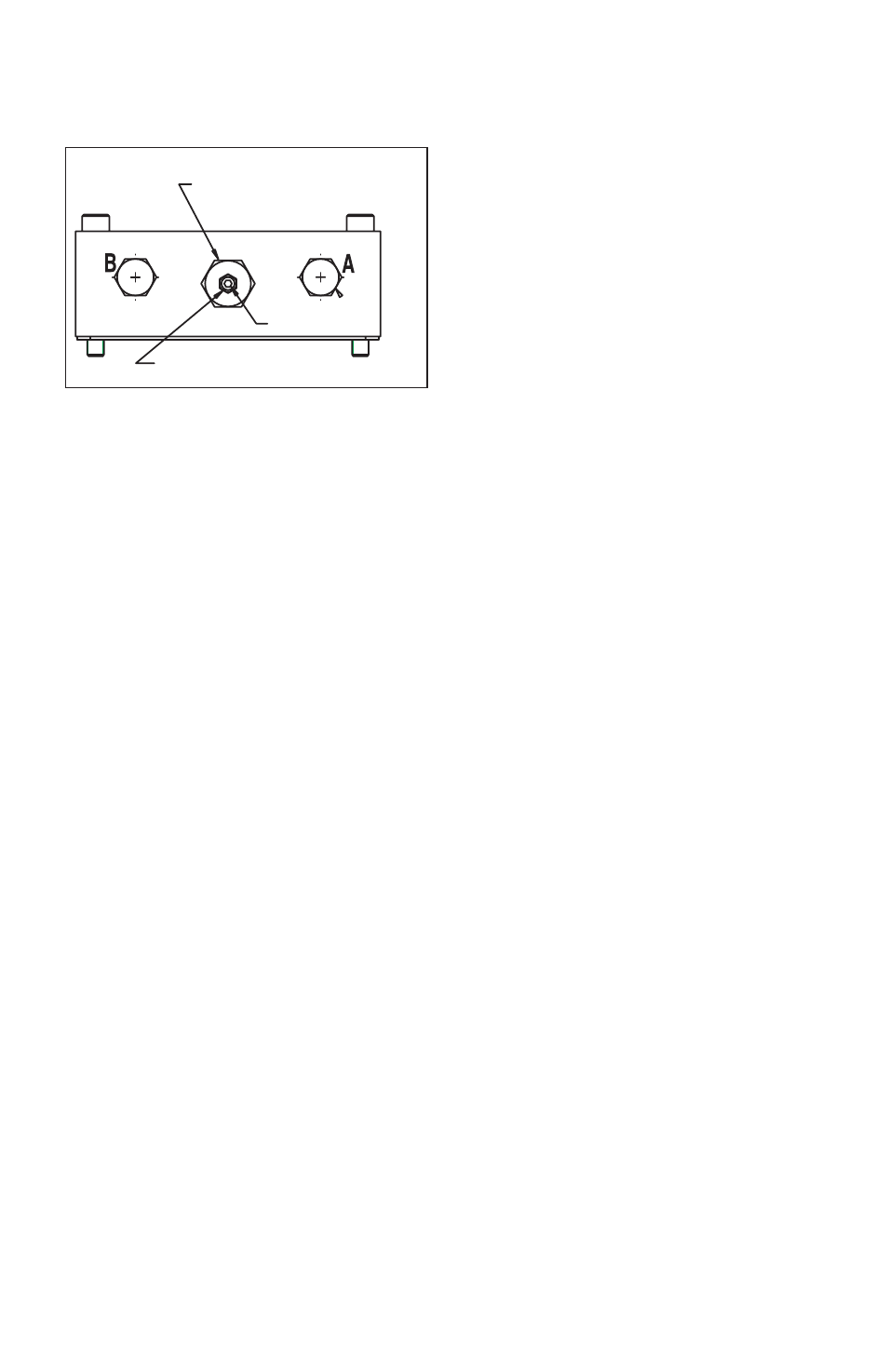

Figure 1

6.0 MAINTENANCE

1. Periodically check all hydraulic connections to be

sure they are tight. Loose or leaking connections

may cause erratic and/or total loss of operation.

Replace or repair all defective parts promptly.

2. Periodically check the hydraulic oil level in your

system. Refer to the oil filling instructions for

complete data.

3. Change hydraulic oil approximately every 250-300

hours of operation. In dusty or dirty areas, it may

be necessary to change the oil more frequently.

7.0 HYDRAULIC SYSTEM

1. Keep all hydraulic components free of dirt,

grease, chips, etc.

2. Keep the hydraulic component operating in areas

that are uncluttered and free of unnecessary

equipment.

3. Periodically check your hydraulic system for

possible loose connections, leaks, etc. Replace

or properly repair damaged or leaking hydraulic

components immediately.

4. Check hydraulic oil in your hydraulic system

every 40 hours of operation or more frequently in

unusually dirty or dusty areas.

5. Oil temperature must be maintained less than or

equal to 150 °F (65 °C) by way of a heat

exchanger or other methods.

8.0 TROUBLESHOOTING

1. If the system will not build pressure, check relief

valves in pump for proper setting (refer to pump

repair sheet). Check and secure all hose

connections. If trouble is not corrected by this

action, remove cylinder and hoses from valve.

Now place a 10,000 PSI gauge directly in valve

port "A" and depress the "up" arrow button. If

pressure cannot be developed, the unit should be

taken to the nearest ENERPAC authorized service

center. If pressure develops, the problem is

located in the cylinder, hoses, or couplers.

2. For VE32 only. After advancing the load, the load

will automatically be held in place. If load drifts,

the unit should be taken to the nearest Enerpac

authorized Service Center.

3. Refer to Repair Parts Sheet L2612 for

"troubleshooting" suggestions.

9.0 STORAGE INSTRUCTIONS

In the event that the unit would be stored for any

prolonged period of time (30 days or more), prepare

the unit as follows:

1. Wipe the entire unit clean.

2. Disconnect all hydraulic and electrical lines to

prevent accidental operation.

3. Cover the unit with some kind of protective cover.

4. Store in a clean, dry environment that is NOT

exposed to extreme temperatures.

3

Relief valve body (DO NOT TURN

relief valve body.)

Locknut

Set screw