Enerpac PU-Series User Manual

Page 4

4

PUD1100B/E, PUD-1101B/E, PUD1300B/E and

PUD1301B/E Models

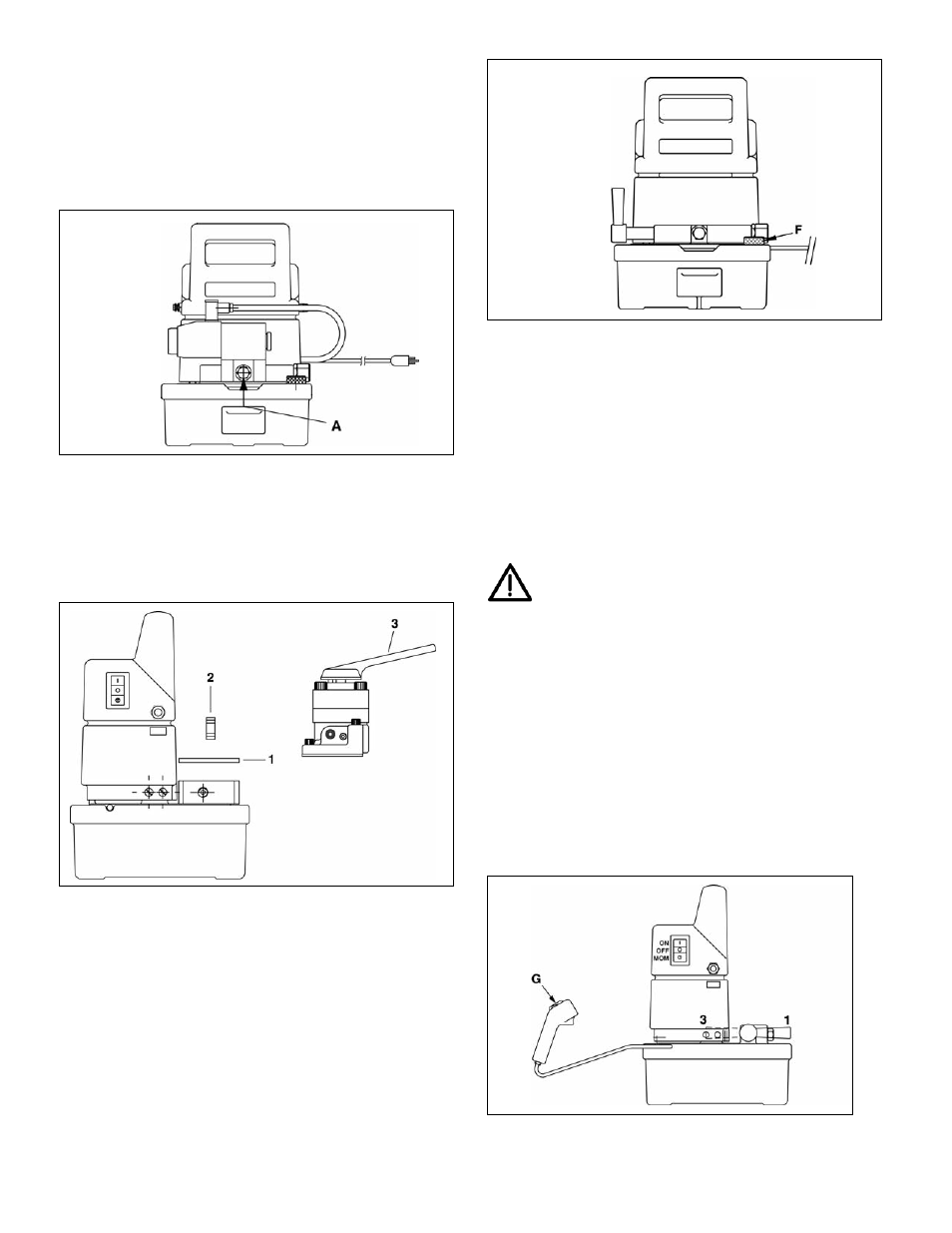

1. The pump-to-cylinder hose attaches directly to the output

port (A) of the control valve (see Figure 4).

2. If a gauge is desired to monitor system pressure, a gauge

adaptor must be installed into the valve outlet port (A). Install

a 0-10,000 psi (700 Bar) pressure gauge into the gauge port

of the gauge adaptor.

Figure 4

4.2 Valve Mounting (Figure 5)

1. Remove the plate (No. 1, D43918098).

2.

Verify that the connector (2) is installed in the pump. If it is

not, install the connector, taking care to avoid shearing the

seals.

Figure 5

3. Mount the valve (3), taking care to avoid shearing the seals.

4.3 Adding Oil (Figure 6)

Check the oil level by unscrewing and removing the vent/fill plug

(F). Add Enerpac hydraulic oil until the oil level is 1/2 inch (1 cm)

below the vent/fill opening.

IMPORTANT: Add oil only when all system components are fully

retracted, or the system will contain more oil than the reservoir

can hold.

Figure 6

5.0 OPERATION

NOTE: To avoid power losses between the electrical outlet and

pump motor, use the shortest possible extension cord. The pump

motor will function at low voltage, but motor speed and oil flow

will be reduced.

1. Check all system fittings and connections to be sure they are

tight and leak free.

2. Check the fluid level and add fluid, if necessary.

3. Open the pump vent plug (F) located on the front right corner

of the reservoir by turning it 1 or 2 complete turns.

CAUTION: The vent plug must be open whenever the

pump is running.

5.1 Switch Operation (Figure 7)

The "B" version requires a 15 amp, 120 V. grounded 1 Ph.

circuit. The "E" version requires 220 V. 1 Ph. The pump power

cord is 5 ft. (1 1/2 meters) long.

1.

The pump switch is located on the side of the shroud. It is a

three position switch, top detent is "ON", middle is "OFF",

bottom is momentary on "MOM". Pressing the top "ON"

position activates the electrical circuit, but does not turn the

pump motor on. The pump motor is activated by the pendant

switch (G).

2. Pressing the lower portion of the switch will activate the

pump motor as long as the switch is held down. Releasing

the switch stops the pump. This momentary position is used

as an alternate to the pendant control.

Figure 7