Enerpac CLP-Series User Manual

Page 2

2

WaRnIng: uSE ExtREmE CautIon

when using high oil flow pumps with

CLP cylinders. oil flow from pump into

cylinder may be higher than the oil flow

capacity of the plunger travel restriction port. oil flow

at the plunger travel restriction port indicates that

maximum plunger travel has been reached. do not

exceed maximum plunger extension with CLP

cylinders.

WaRnIng: CLP cylinders do not have

a stopring. use these cylinders only in

vertical position with the plunger pointing

upwards.

WaRnIng: do not ExCEEd EquIP-

mEnt RatIngS. never attemp to lift a

load weighing more than the capacity of

the cylinder. overloading causes equip-

ment failure and possible personal injury. These

cylinders are designed for a maximum pressure of

700 bar [10,000 psi]. do not connect these cylinders

to a pump with a higher pressure rating.

ImPoRtant: use hydraulic gauges in

each hydraulic system to indicate safe

operating loads.

WaRnIng: off-center loads produce

unnecessary strain on cylinders and

create potential safety hazards. avoid

point loading. distribute the load evenly

across the entire plunger surface.

WaRnIng: Stay clear of loads supported

by hydraulics. after the load has been

raised or lowered, it must be blocked.

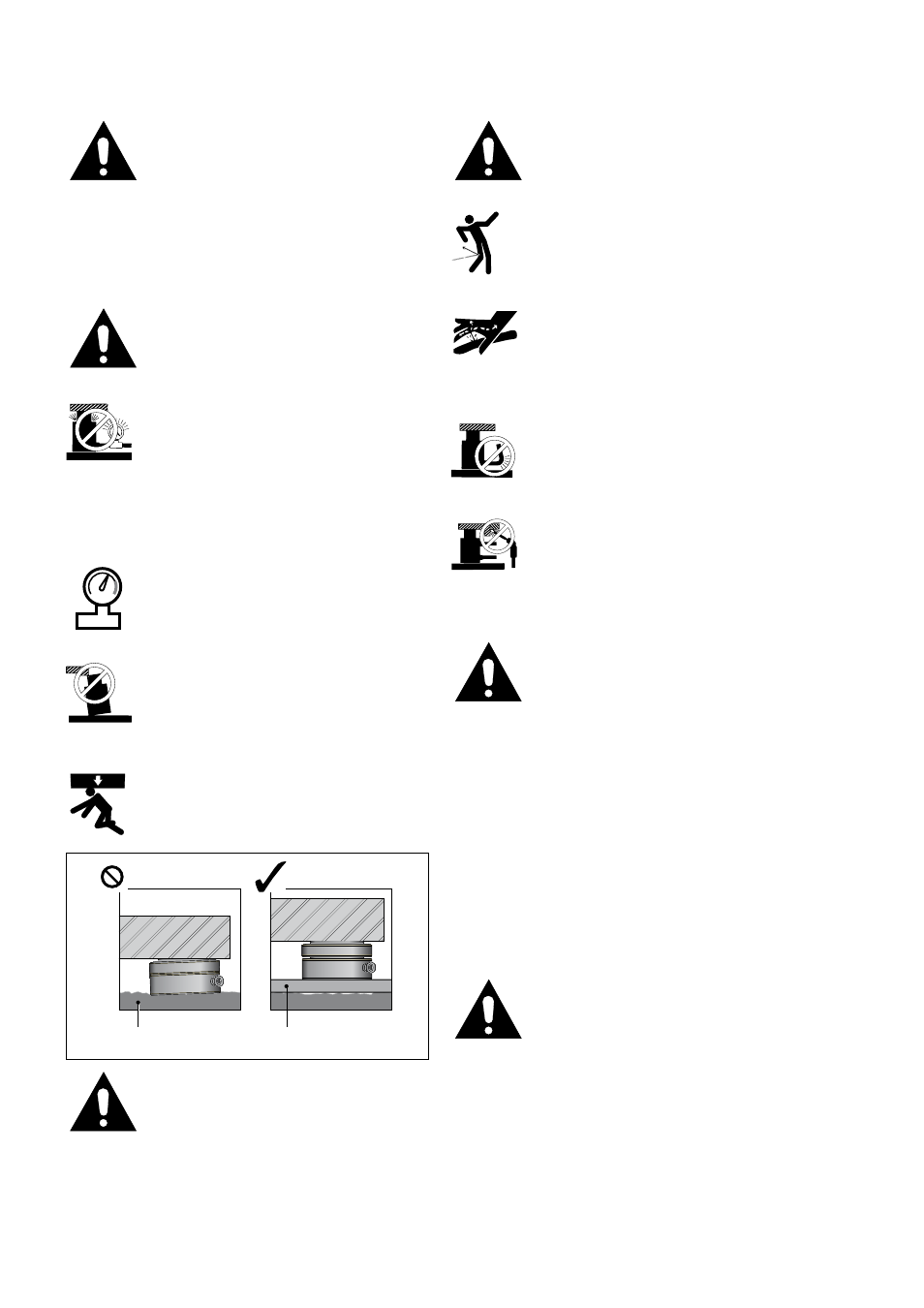

CautIon: Provide a solid support for

the entire base area. all Clp-Series

cylinders require a solid, flat lifting

surface capable of supporting the load

to be lifted. use of Clp cylinders on surfaces such

as sand, mud or dirt may result in cylinder damage.

WaRnIng: nEvER release hydraulic

pressure before the load is

mechanically blocked with lock nut

well positioned against cylinder base.

WaRnIng: nEvER PRESSuRIzE

unCouPLEd CouPLERS. only use

hydraulic equipment in a coupled system.

dangER: do not handle pressurized

hoses. Escaping oil under pressure

can penetrate the skin, causing serious

injury. If oil is injected under the skin, see

a doctor immediately.

CautIon: avoid sharp bends and

kinks that will cause severe back-up

pressure in hoses. Bends and kinks lead

to premature hose failure damage.

WaRnIng: Make sure that all system

components are protected from external

sources of damage, such as excessive

heat, flame, moving machine parts, sharp

edges and corrosive chemicals.

4.0 SIdELoad

ImPoRtant: Eliminate the presence

of sideload forces when using CLP

cylinders.

Sideload can occur through:

1. an eccentric load on the plunger.

2. a horizontal load on a structure.

3. a structure and/or cylinder misalignment.

4. non synchronized lifting actions.

5. non stable cylinder base support.

always use a flat, hard surface as a cylinder support

plate. use a low friction material on top of the saddle.

always use grease underneath swivel saddles (see

illustration 3 on page 4). The maximum allowable

sideload is 3% of the cylinder’s rated capacity.

5.0 oPERatIon

ImPoRtant: It is mandatory that the

operator has a full understanding of all

instructions, safety regulations, cautions

and warnings, before starting to operate

any of this high force tool equipment. In case of

doubt, contact Enerpac.

WRong

Rough soil

Flat, solid lifting

surface

RIgHt