Enerpac BRD-Series User Manual

Page 3

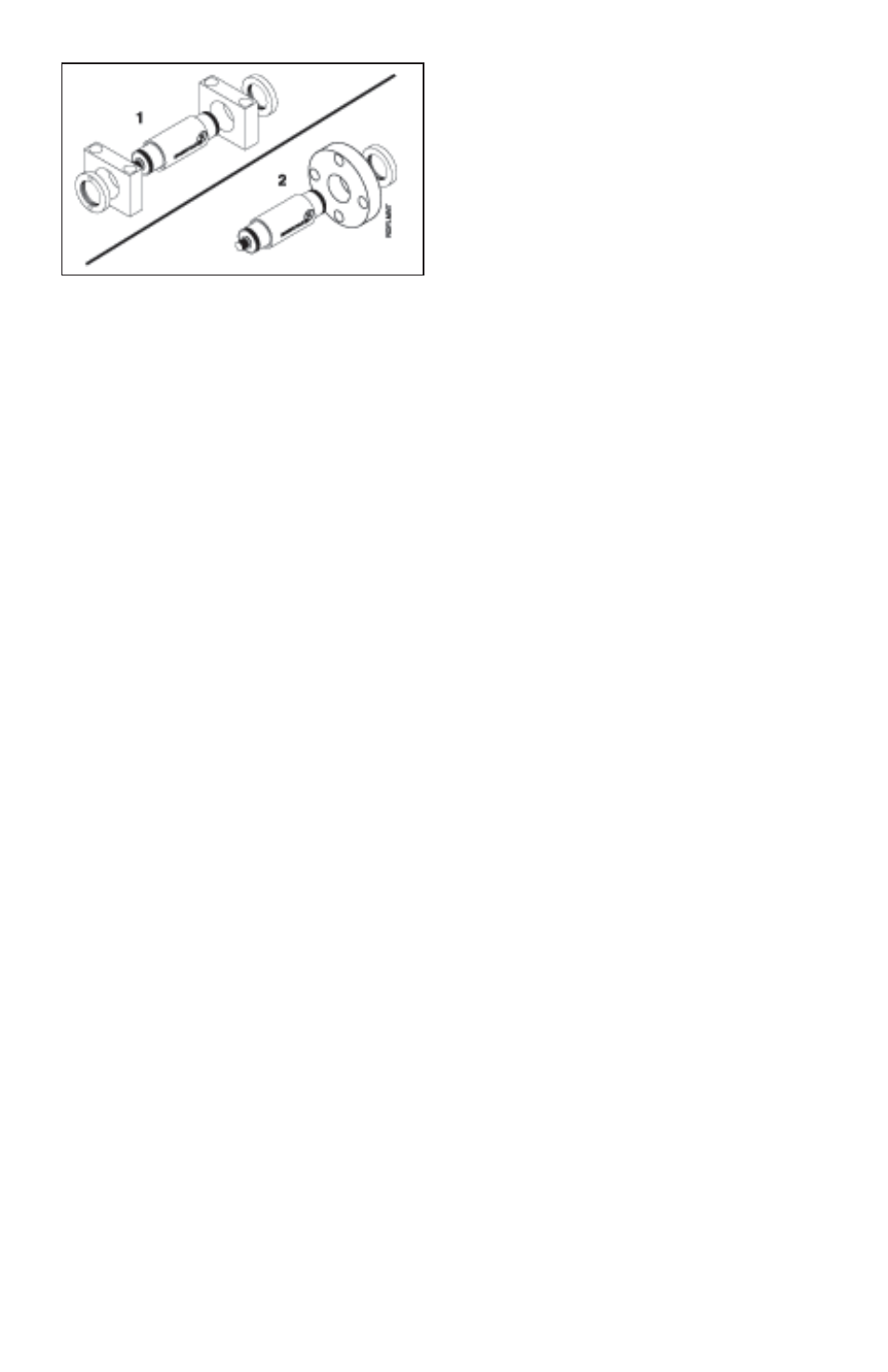

3. Make hydraulic connections. Use a pump

with a 4-way valve and two hydraulic lines.

Be sure all hydraulic lines are connected to

the correct inlet and outlet ports of the pump,

cylinder, valves, and other system

components.

All BRD and RD cylinders are equipped with

two 3/8"-18 NPT oil ports to allow for solid

pipe connections. When using flexible hose,

high-flow C-604 female couplers are

recommended.

Seal all pipe connections with a high grade

pipe thread sealer. If you use Teflon tape,

leave the first complete thread free of tape

to ensure that tape does not shed into the

hydraulic system, causing damage. Trim

loose ends.

IMPORTANT:

Both oil ports must be

connected to a hydraulic line. These

cylinders do not have a safety valve to

prevent over pressurizing. If one of the oil

ports is plugged, the pressure may exceed

10,000 psi (700 bar).

4. Remove air from the system by extending

and retracting the cylinder 2 or 3 times.

4.0 OPERATION

Operate the hydraulic pump to advance and

retract the cylinder. Double-acting operation

develops both push and pull forces. However,

the capacity is higher when pushing and the

speed higher when pulling. See the Enerpac

catalog for specifications.

The cylinder stop ring is designed to take the

full load. However, to reduce cylinder wear, use

less than full stroke when possible.

5.0 MAINTENANCE

1. Use only Enerpac oil with these cylinders.

The use of any other oil may invalidate your

warranty.

2. Use dust caps when cylinders are

disconnected. Keep entire cylinder clean to

prolong cylinder life.

3. Store cylinders up-right to prevent seal

distortion.

6.0 TROUBLE SHOOTING

These cylinders should be repaired only by

Authorized Enerpac Technical Service Centers.

3