Enerpac BRD-Series User Manual

Page 2

2

CAUTION:

Avoid damaging hydraulic

hose. Avoid sharp bends and kinks

when routing hydraulic hoses. Using

a bent or kinked hose will cause

severe back-pressure. Sharp bends and kinks

will internally damage the hose leading to

premature hose failure.

Do not

drop heavy objects on hose. A

sharp impact may cause internal

damage to hose wire strands.

Applying pressure to a damaged hose may

cause it to rupture.

IMPORTANT:

Do not lift hydraulic

equipment by the hoses or swivel

couplers. Use the carrying handle or

other means of safe transport.

CAUTION: KEEP HYDRAULIC

EQUIPMENT AWAY FROM

FLAMES AND HEAT.

Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens hose

materials and packings.

For optimum

performance do not expose equipment to

temperatures of 65°C [150°F] or higher. Protect

hoses and cylinders from weld spatter.

DANGER: DO NOT HANDLE

PRESSURIZED HOSES.

Escaping

oil under pressure can penetrate the

skin, causing serious injury. If oil is injected

under the skin, see a doctor immediately.

WARNING:

Only use hydraulic

cylinders in a coupled system. Never

use a cylinder with unconnected

couplers. If the cylinder becomes

extremely overloaded, components can fail

catastrophically causing severe personal injury.

WARNING: BE SURE SETUP IS

STABLE BEFORE LIFTING LOAD.

Cylinders should be placed on a flat

surface that can support the load.

Where applicable, use a cylinder base for

added stability. Do not weld or otherwise modify

the cylinder to attach a base or other support.

Avoid

situations where loads are not

directly centered on the cylinder

plunger. Off-center loads produce

considerable strain on cylinders and plungers.

In addition, the load may slip or fall, causing

potentially dangerous results.

Distribute the load evenly across the

entire saddle surface. Always use a

saddle to protect the plunger.

IMPORTANT:

Hydraulic equipment

must only be serviced by a qualified

hydraulic technician.

For repair

service, contact the Authorized

ENERPAC Service Center in your area. To

protect your warranty, use only ENERPAC oil.

WARNING:

Immediately replace worn

or damaged parts by genuine

ENERPAC parts. Standard grade

parts will break causing personal injury and

property damage. ENERPAC parts are designed

to fit properly and withstand high loads.

WARNING:

Both oil ports must be

connected to a hydraulic line. These

cylinders do not have a safety valve

to prevent over pressurizing. If one of the oil

ports is plugged, the pressure may exceed

10,000 psi (700 bar) during operation.

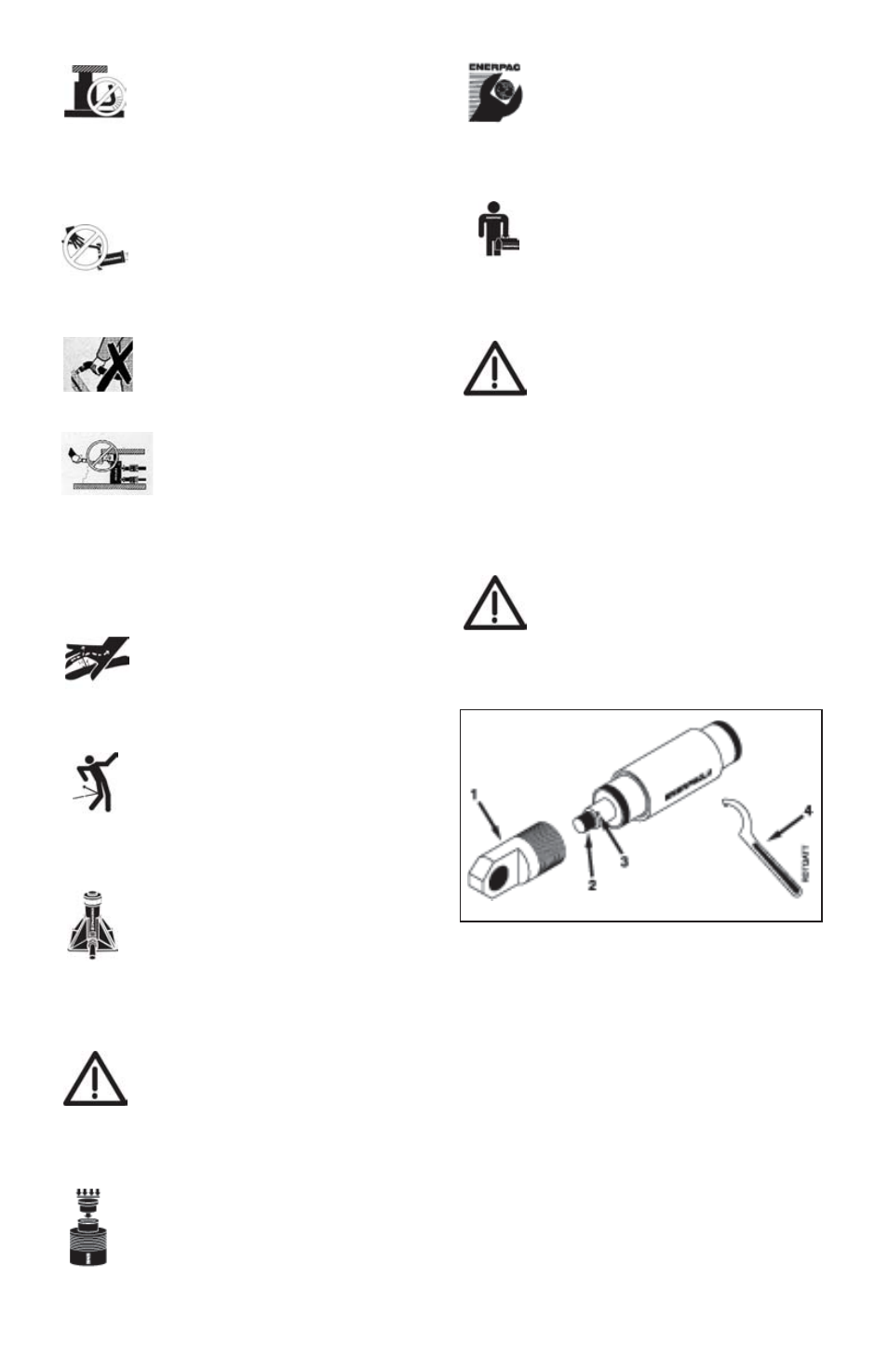

3.0 INSTALLATION

1. Install attachments.

CAUTION: USE PLUNGER HOLE

(3) TO PREVENT ROTATION OF

PLUNGER WHEN INSTALLING

AND TORQUING ATTACHMENTS.

Rotating

the plunger will damage the inside of the

cylinder.

When tightening attachments (1) to the plunger

threads (2), use the hole (3) to prevent the

plunger from turning. Hold the plunger in place

by using a pin (or spanner) wrench (4).

Torque requirements vary according to

application and type of attachment. Excessive

tightening can damage cylinder parts and/or

attachments.

2. Mount cylinder. Base mounting (1) and

flange mounting (2) attachments are shown

below.