Enerpac LW-Series User Manual

Page 4

4

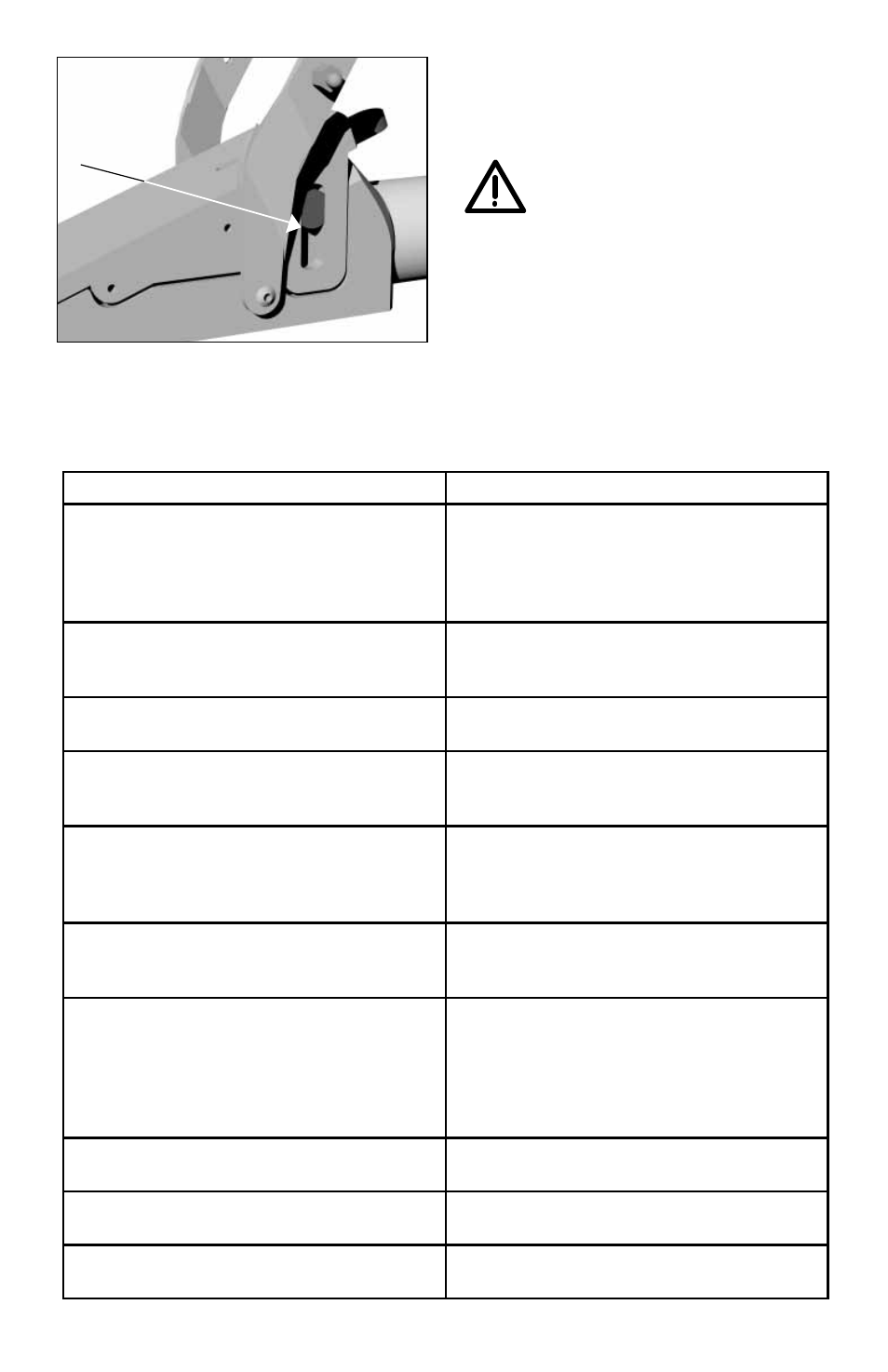

Grease

4.

Machined surfaces and moving parts should be

liberally coated with grease PRIOR to each use.

Without lubrication, the driving wedge is subject to

galling, and possible binding during retract stroke.

5.

PRIOR to each use, examine Lifting Wedge for

loose or damaged parts. Tighten or replace

any suspect parts. Failure to properly maintain

Lifting Wedge may result in catastrophic failure

or personal injury.

WARNING: DO NOT repair bent lifting

jaws; replace with new parts.

NOTE: Lower Jaw (Main Body) is not repairable and

not replaceable. For safety, replace entire Lifting

Wedge.

6.0 TROUBLESHOOTING

These cylinders should be repaired only by Authorized

Enerpac Technical Service Centers. Single-acting

cylinders are spring-loaded and require special

disassembly techniques to prevent personal injury.

Problem

Possible Cause

Lifting Wedge will not advance.

Pump release valve open.

Coupler not fully tightened.

Oil level in pump is low.

Pump malfunctioning.

Load is too heavy for Lifting Wedge.

Lifting Wedge advances part way.

Oil level in pump is low.

Coupler not fully tightened.

Lifting Wedge plunger binding.

Lifting Wedge advances in spurts.

Air in hydraulic system.

Lifting Wedge plunger binding.

Lifting Wedge advances slower than normal.

Leaking connection.

Coupler not fully tightened.

Pump malfunctioning.

Lifting Wedge advances but will not hold.

Lifting Wedge drive cylinder seals leaking.

Pump malfunctioning.

Leaking connection.

Incorrect system set-up.

Lifting Wedge drive cylinder leaks oil.

Worn or damaged seals.

Internal Lifting Wedge drive cylinder damage.

Loose connection.

Lifting Wedge will not retract or retracts

slower than normal.

Pump release valve is closed.

Coupler not fully tightened.

Pump reservoir over-fi lled.

Narrow hose restricting fl ow.

Broken or weak retraction spring.

Lifting Wedge damaged internally.

Oil leaking from external relief valve.

Coupler not fully tightened.

Restriction in return line.

Lifting Wedge advances but doesn’t retract

under load.

Inadequate drive wedge lubrication.

Lifting Wedge jaws are bent.

Load shift.

Load too heavy for Lifting Wedge.