Warning – Elkhart Brass X-Stream SM1000BE – SM2000BE HL/HLGM User Manual

Page 8

8

VII MAINTENANCE

Monthly Inspection and Maintenance (or after each use):

1. Cycle nozzle through all functions (straight stream, fog, etc.) to confirm that it is fully functional. If

any hesitation in movement is seen, follow steps 2 through 5.

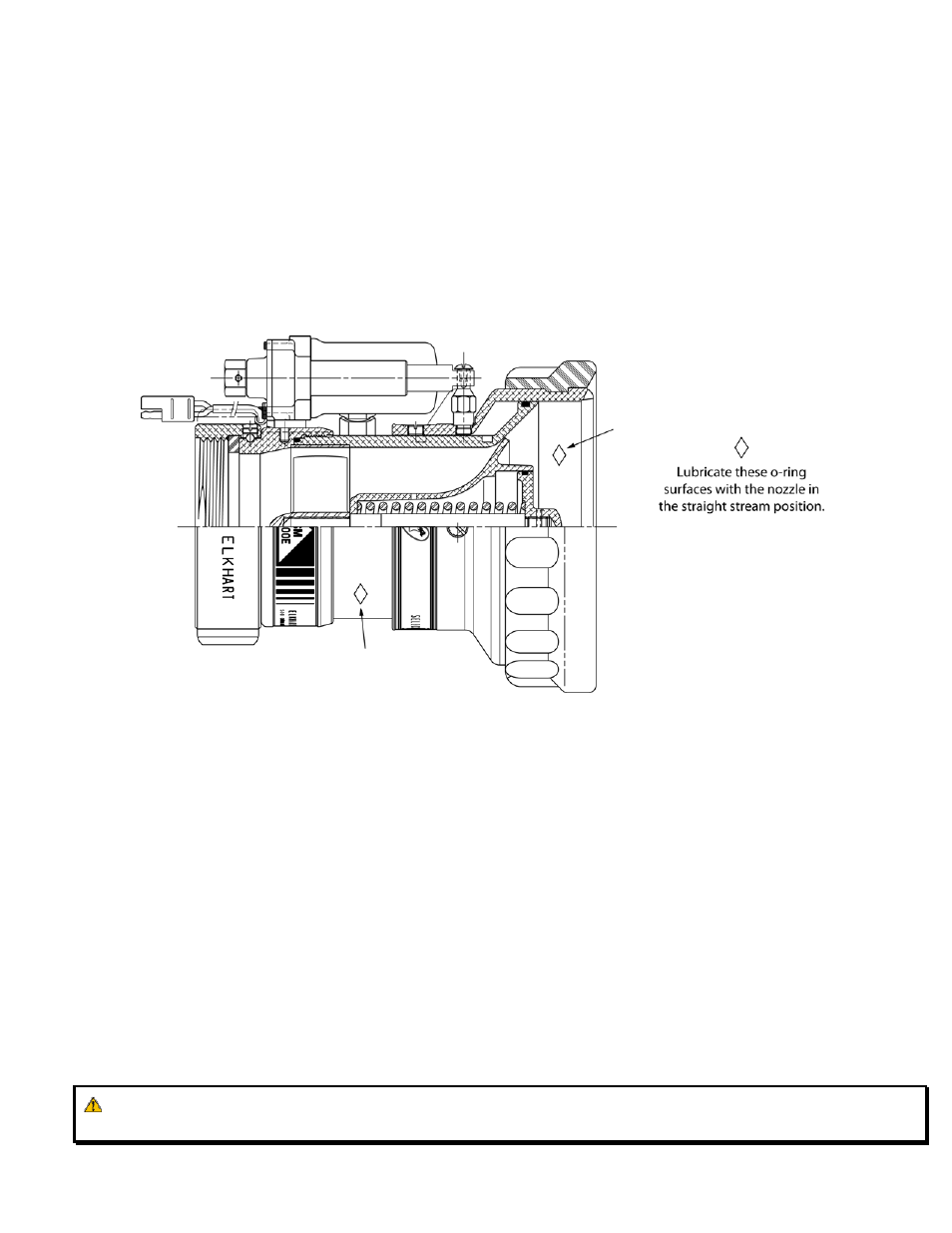

2. Apply a thin coating of Dow Corning #7 silicone grease or equivalent to the surfaces that the nozzle

tip o-rings move across (See Illustration Below). Coat these surfaces with grease while the nozzle is in

the straight stream position (all the way forward).

3. Run the tip back and forth through its full range of motion several times to distribute the grease.

4. Stop the nozzle tip in the wide fog position (all the way back) and wipe off any excess grease.

5. Run the nozzle through its entire range of motion at least once a week.

Six-Month Inspection and Maintenance:

1. Check motor control cables for wear and connectors for damage.

2. Check motor cables for binding through full movement of monitor and nozzle.

3. Check all painted surface for chips or scratches, and repaint as required.

4. Visually check all electrical equipment.

VIII TROUBLESHOOTING

A. If nozzle stream cone is not tight; take nozzle and stream shaper off monitor and clean debris out of

both. Flush firewater lines with nozzle and stream shaper off monitor, then reassemble.

B. If nozzle will not move (to straight stream or fog); check electrical connection to make sure it is tight.

If the electrical connection is tight and nozzle still will not move, manually cycle nozzle three (3)

times, then try to move it electrically.

C. Check for power at nozzle connection

Any problems that cannot be fixed/solved with this troubleshooting guide should be taken to your

Elkhart Brass Representative to get further information.

WARNING:

Do not attempt to disconnect or work on any electrical equipment in this

system unless power is removed or the area is known to be non-hazardous.

(Image shown may differ from actual nozzle)