98342030_pumper_quick_install_3.22.11, Scorpion, Typical pumper truck install guide – Elkhart Brass Scorpion Typical Pumper Truck Install Guide User Manual

Page 2

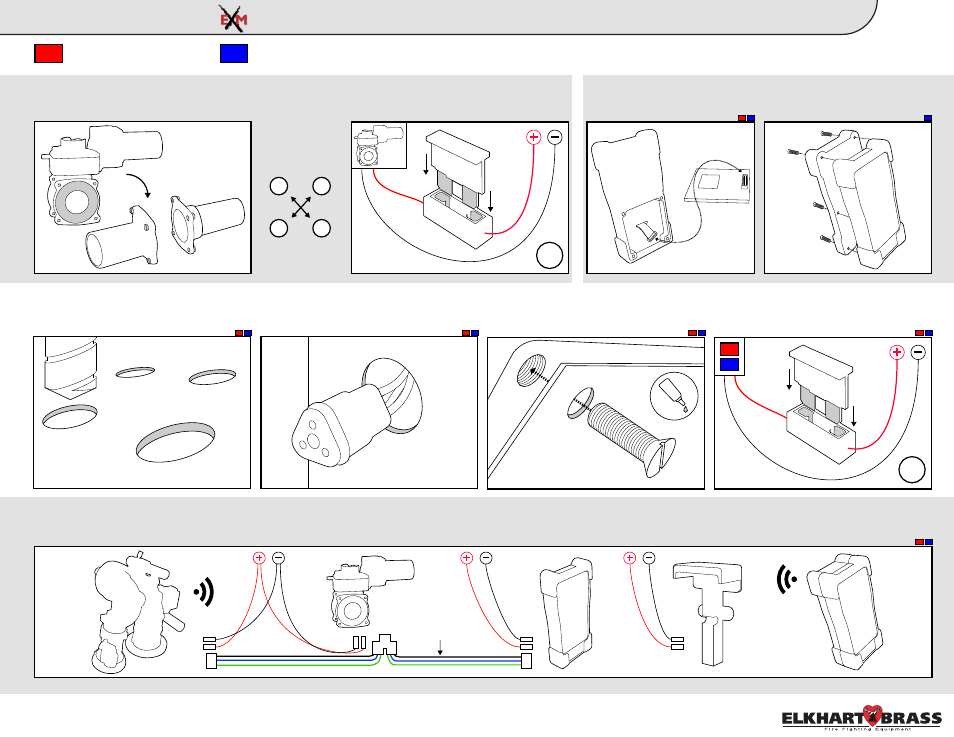

Typical Pumper Truck Install Guide:

Control Components & Accessories

2

4.

5.

6.

A. Follow mounting templates on page

30 of the instruction manual for hole

diameters and dimensions.

B. Drill holes for CAN network and

power cables for each components’

leads behind each component.

C. Mount components to panel using

10-24 x 1/2” screws. Use Loctite 242 or

equivalent.

D. Add a 1A (12VDC)* fuse between

red component lead and positive power

lead.

A. Connect entire CAN network together using 18-22 AWG. Ensure every component connected to the CAN network is connected in between 2 end components that

have CAN termination. Please refer to the BLUE, GREEN, and BLACK lines as the CAN wires below.

*.5A (24VDC)

A. Install valve into plumbing. Torque

adapter bolts to spec using torque specs

to the right

.

7/32” dia.

unless noted

CAN

Network

Wires

18g

98342030 Rev. Rel

1

3

4

2

Tighten Adapter

Bolts using a

cross pattern

EB40:

60-70 ft-lbs

B. Add a 30A(12VDC)* fuse between

RED controller lead and positive power

lead. *15A(24VDC)

16g

- Panel Mount Controller

Handheld Controller / Docking Station

-

Before continuing please follow the steps on page 14 of the Scorpion EXM instruction manual outlining the

EXM Configuration Tool.

Connect power and attach

battery pack to Handheld

controller.

RF Installation - The RF

Module will be upside down

when installed correctly.

SCORPION