Elkhart Brass Scorpion Typical Pumper Truck Install Guide User Manual

Monitor nozzle, Scorpion, Typical pumper truck install guide

Typical Pumper Truck Install Guide:

Monitor & Nozzle

MONITOR

NOZZLE

1

SCORPION

1.

2.

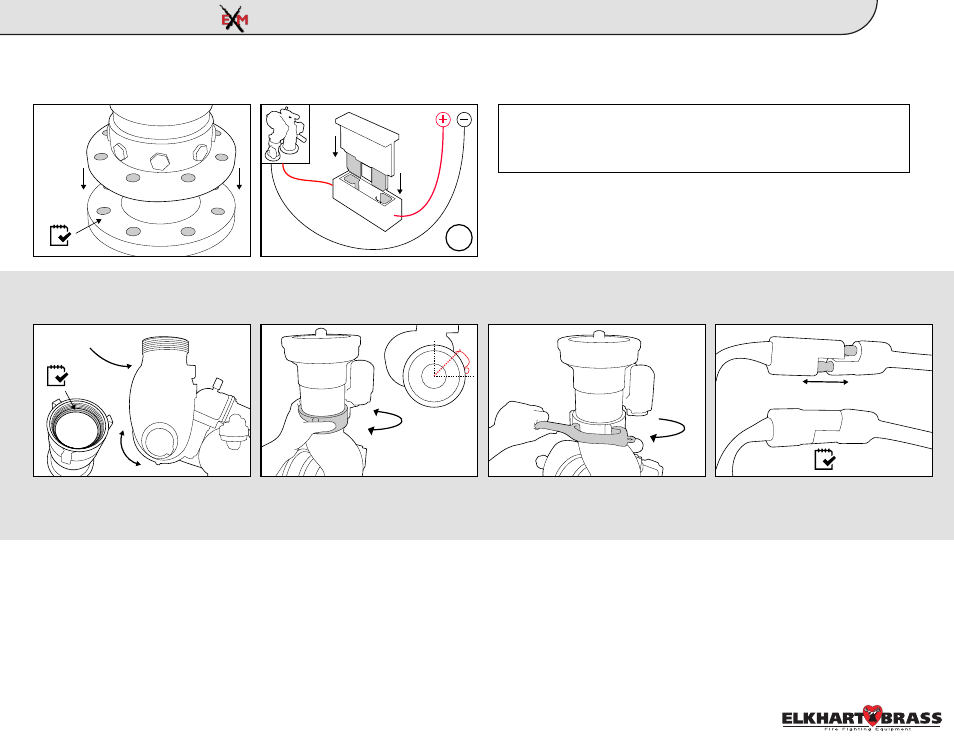

A. Install monitor to flange using 5/8”-11

UNC Grade 5 bolts and nuts. Tighten

uniformly to 70ft/lb using Loctite 242 or

equivalent.

B. Add a 20A(12VDC)* fuse between

RED controller lead and positive power

lead. Use 40A fuse if nozzle with foam

expansion tube is utilized.

NOTE: We recommend using 14 AWG for monitor power and ground (12

AWG if using nozzle with foam expansion tube). See Scorpion EXM

monitor installation guide on page 9 of the manual for length to gauge

recommendations.

A. Position monitor discharge elbow

vertical. Ensure gasket is inside nozzle

swivel before installing.

B. Hand tighten nozzle to monitor using

swivel end piece. Position actuator

assembly about 45° around the swivel.

*10A(24VDC)

C. Tighten swivel using a spanner

wrench to ensure a secure connection.

D. Connect nozzle and monitor two-way

connectors.

3.

Confirm that all connections are tight and all electrical connections have been reconnected. If installing additional components, such as controllers, you may choose to

double check the connections after everything has been installed.

180°

0° 45°

16g

98342030 Rev. Rel

Gasket or

Sealant