Disassembly procedure assembly procedure – Condux Break-Away D.Drill Swivels User Manual

Page 6

7

6

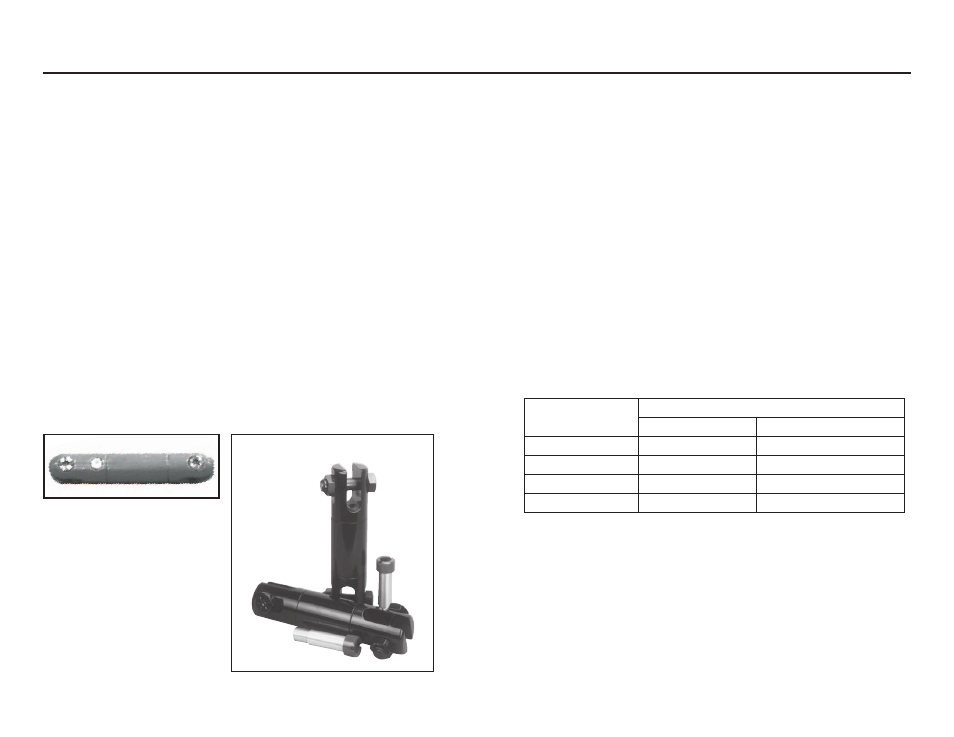

Disassembly Procedure

Assembly Procedure

1. Remove the

clevis pins (1

1

⁄

4

" & 1

3

⁄

8

") or

clevis bolts and nuts

(1

5

⁄

8

" - 4") from the swivel.

2. Remove the

setscrew from the side of the swivel (1

5

⁄

8

" - 4").

3. Drive the

roll pin out of the swivel (1

5

⁄

8

" - 4"). Use a roll pin punch and

remove the pin completely.

4. Remove the broken pin’s shaft from the

internally threaded head.

You may need to apply heat (use a propane torch) to the threads on

the break pin to loosen the Threadlocking Compound existing on the

threads.

5. Hold the

body of the swivel securely in an appropriate vise. Hold the

swivel near the

internally threaded head. Use soft jaws, a pipe vise

or a strap wrench if possible. Tighten the vise but do not over-tighten.

Overtightening of the vise may collapse the body and permanently

deform the swivel.

6. Remove the

externally threaded head of the swivel. You may need to

apply heat to the outside of the swivel to break down the

Threadlocking Compound existing on the threads.

7. Remove the bearings and seals from the swivel.

Take note of the

bearing and seal orientation as they are removed to assure

proper replacement.

1. Clean I.D. of bearings, external and internal threads free of oil,

grease, old Threadlocking Compound and anti-seize compound and

replace any parts that are defective.

2.

The bearings and seals must be assembled as shown in the

swivel drawing (see Diagram 1 or 2).

3. Slide the bearings onto the break pin’s shaft (see Table 2 for correct

replacement break pin). Do not force the bearings - it could damage

the pin.

4. Apply Threadlocking Primer to the threads of the center pin and to the

threads on the externally threaded head. Apply Removable

Threadlocking Compound to the same threads. Do not apply

Threadlocking Compound to clevis pin (1

1

⁄

4

" & 1

3

⁄

8

") or clevis bolt or

nut (1

5

⁄

8

" - 4").

5. Insert the break pin and bearings into the

swivel body. Screw the

break pin into the internally threaded head and tighten until snug.

Do

not overtighten.

6. Torque break pin and externally threaded head to the following

specifications table (Table 1):

7. Using hole in swivel body, re-drill hole thru Center Break Pin. Press

Roll Pin thru Head and Center Break Pin until Roll Pin is centered in

Head (1

5

⁄

8

" - 4" swivels only).

8. Screw External Threaded Head back into the Body. Screw until snug

and then align Setscrew holes. Install Setscrew in Body and Head

(1

5

⁄

8

" - 4" swivels only).

1

1

⁄

4

" & 1

3

⁄

8

" Dia. Swivel

1

5

⁄

8

" - 4" Dia. Swivel

Swivel

Diameter

Torque Value

Break Pin

External Threaded Head

1 1/4"

10-15 in-lbs

20-25 ft-lbs

1 3/8"

10-15 in-lbs

20-25 ft-lbs

1 5/8"

15-20 in-lbs

90-100 ft-lbs

2" - 4"

15-20 in-lbs

120-130 ft-lbs

Table 1