Barranca Diamond HP30 Slab Saw User Manual

Page 17

17

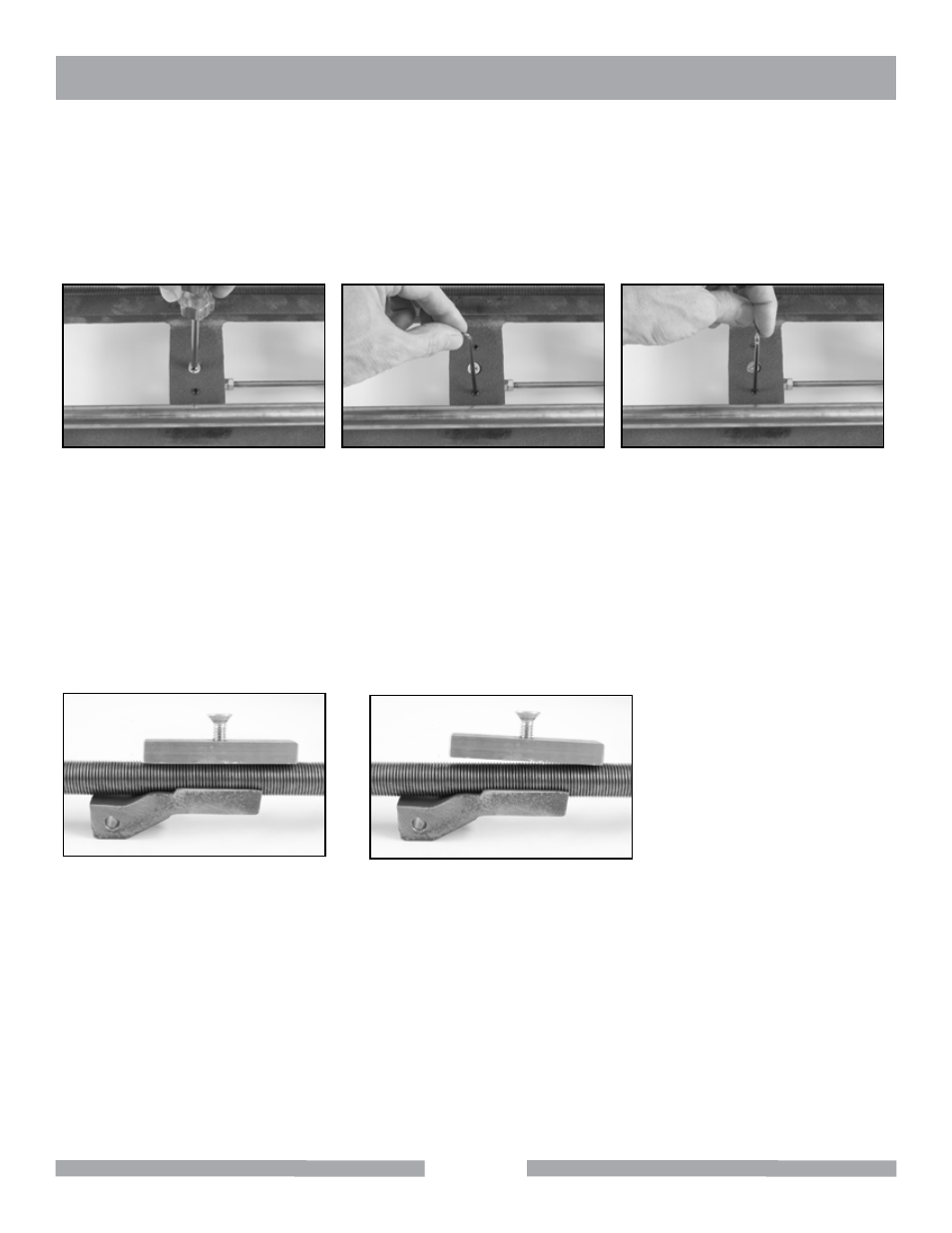

Above the pressure block in the carriage, there are two allen head set screws that are used to adjust the height

of the pressure block. There is also a flat head machine screw that locks the pressure block in place (fig. 6).

To adjust the pressure block, first loosen the flat head machine screw that locks the pressure block (fig. 7).

Then use an allen wrench (fig. 8) to rotate each of the two set screws one-quarter turn (fig. 9) in a clock-wise

direction.

Fig. 7: Pressure block locking

screw

Fig. 8: Allen head wrench in

front set screw

Fig. 9: Allen head set screw ro-

tated 1/4 turn

Retighten flat head screw after adjusting the two set screws. Re-engage the clutch and restart saw to check if

feed is working properly. If the carriage feed is still not working properly, repeat the adjustment procedure and

restart saw to check feed.

Adjustment of the clutch and pressure block must result in an even, flat position against the feed screw when

clutch block is engaged (fig. 10). Uneven adjustment of set screws will put pressure on one end of clutch (fig.

11), causing premature part failure and/or binding of the feed screw.

HP30

OPERATIONS & ADJUSTMENTS

Fig. 10: Pressure block flat against

feed screw

Fig. 11: Pressure block improperly

adjusted