Barranca Diamond HP30 Slab Saw User Manual

Page 16

16

Clutch Adjustment Procedure

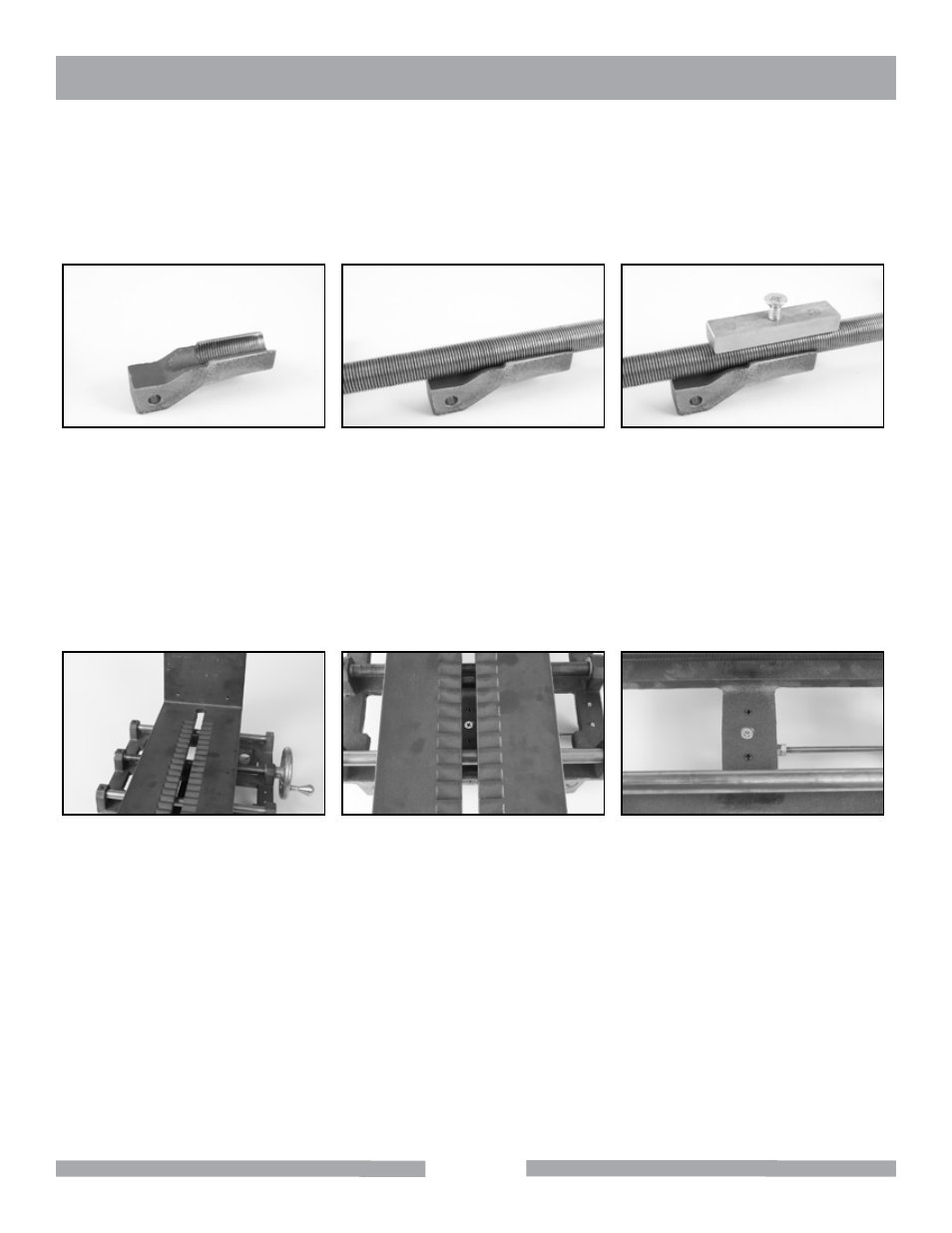

The clutch system on HP Slab Saw is comprised of three main components: a bronze clutch shoe (fig. 1) that

is raised and lowered by a lever activated cam (not shown), the feed screw (fig. 2) that drives the vise carriage

when the clutch assembly is engaged, and the brass pressure block (fig. 3) that applies downward pressure

against the feed screw to keep it engaged with the clutch block.

Fig. 1: Clutch block

Fig. 2: Clutch block & feed

screw

Fig. 3: Clutch assembly with

pressure block

Over time, the brass pressure block can wear due to contact with the rotating feed screw. This can cause the

clutch block to not properly engage the feed screw. Should the clutch block not fully engage the carriage will

not travel properly and the position of the pressure block will need to be adjusted. To access the pressure block

adjustments, use the cross feed handle to move the center slot in the vise assembly (fig. 4) so that the clutch

block adjustment screws are visible through the slot (fig. 5). In Figure 6, the vise has been removed from the

carriage assembly to clearly show the clutch block adjustment screws.

Fig 4: Vise assembly

Fig 5: Vise assembly centered

over clutch block adjustment

screws

Fig 6: Clutch block adjustment

screws

HP30

OPERATIONS & ADJUSTMENTS