Super cabmaker gp8 operation and adjustment – Barranca Diamond SUPER CABMAKER-GP8 User Manual

Page 17

17

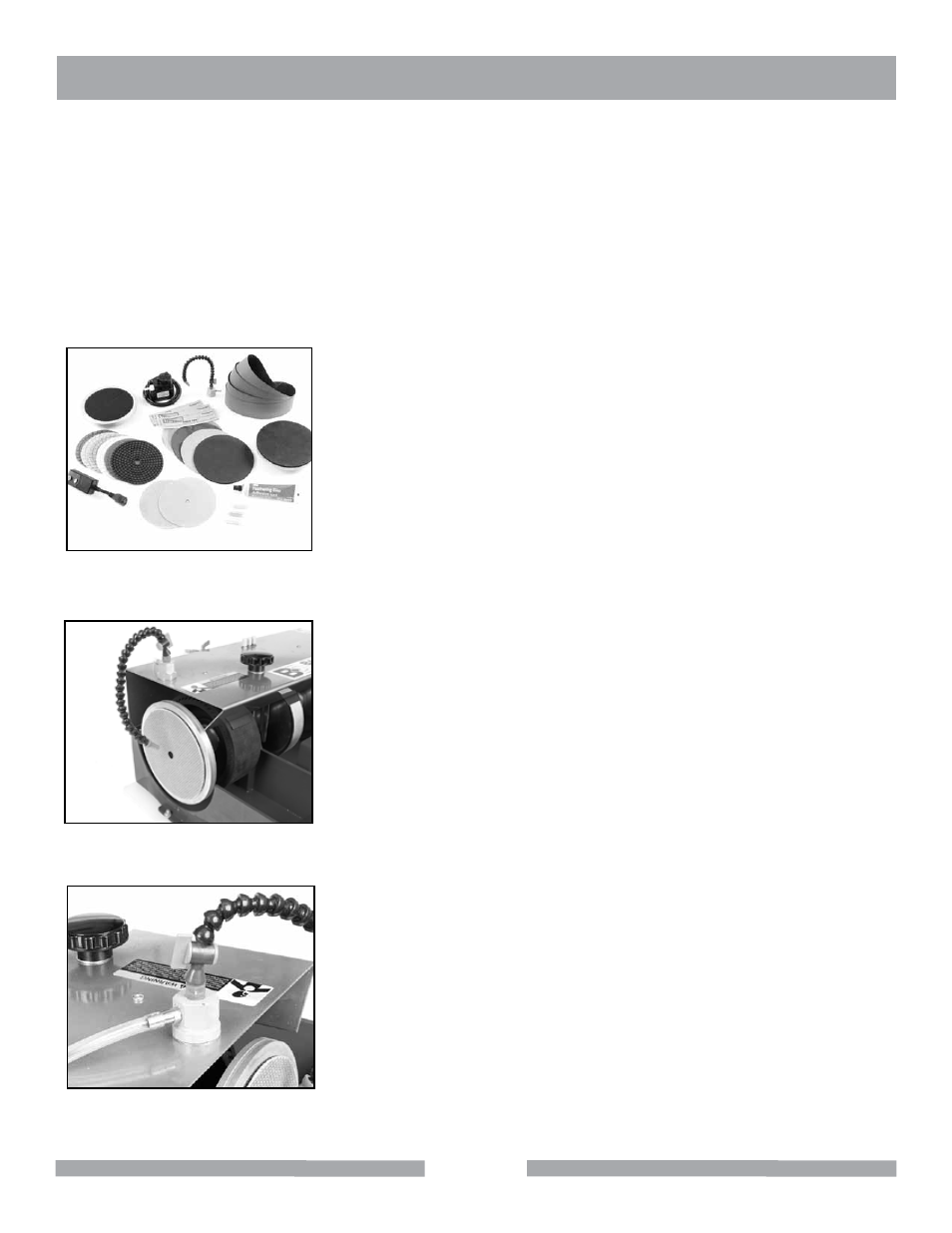

SANDING AND POLISHING FLAT (7" DISCS) Option 2 (Accessories)

GP8 Supercabmaker employs an 8" end of shaft aluminum faced hook

lined flat polishing system that mounts on the left hand end of the main

arbor shaft. User will have to first remove the convex rubber faced alumi-

num disc (left hand thread, rotate disc clockwise to loosen and remove).

Once removed, thread on the flat faced hook lined 8" aluminum flat

sanding/polishing disc which will act as a backer mounting disc to the 7"

electroplated sanding pads and 7" resin diamond polishing pads (Fig 17).

A LockLine manifold (magnetic base) and flexible nozzle line system

must be used in with these 7" sanding and polishing pads to direct cool-

ing/flushing water in a mist spray onto the electroplated and resin dimond

surfaces mounted vertically with hook & loop on the aluminum flat faced

disc (Fig 18).

The LockLine magnetic base mounted nozzle will need to be attached

with 3/8" OD x 1/4" ID clear plastic tubing to the submersible water pump

placed in a 5 gallon bucket to provide a supply of clean cooling water (do

not recycle dirty water to the LockLine system). The clear water feed tub-

ing will connect to the LockLine manifold at a brass barb fitting (Fig 29).

Water flow is controlled by adjusting the plastic knob on the LockLine

flexible line so that a fine mist is dispensed onto the center face of the 7"

electroplated and resin diamond polishing pads.

To use 7" sanding electroplated diamond pads (70 and 120 grit), first

mount the pad centered over the hook lined flat aluminum disc, position

the LockLine nozzle to center of the pad and turn on the GP8 main power

switch. The submersible pump will need to be plugged into the acces-

sory receptacle (female) on the On/Off switch box. After a few seconds,

the pump will deliver water through the feed clear tubing to the LockLine

manifold and flexible nozzle where the spray mist can be regulated. Only

a fine mist is required to flush and cool the electroplated pads while

sanding saw and grinding marks out of a gemstone specimen. Move

the specimen face to be sanding slowly across the lower 1/2 face of the

electroplated pad (70 grit) and periodically inspect the gemstone face by

drying to determine whether the saw and or grinding marks have been

sufficiently removed (Fig 20).

Fig 18 - LockLine & Nozzle connected

Fig 17 - Accessories Option 2

Fig 19 - Connection tube and valve

Use only one dedicated Polytex polishing pad with each respective diamond paste syringe (i.e. keep a labeled

Polytex pad for the 8,000 grit paste in a zip-lock bag labeled 8,000 grit). Do not use a single Polytex pad with

two or more diamond pastes or else cross-contamination and poor polishing of the gemstone material may

result.

The Polytex pad can be removed from the foam rubber covering of the convex polishing disc by slowly pull-

ing the Polytex pad off the foam and placing it in a zip-lock plastic bag properly labeled with the syringe paste

diamond grit size for future use. No water or extender fluid is needed to effectively disperse the diamond paste

from the syringe to the Polytex pads. If the adhesive backing becomes weak with repeated use, you can apply

a few drops of 3M On/Off adhesive to improve the adhesive connection to the foam disc.

SUPER CABMAKER GP8

OPERATION AND ADJUSTMENT