Barranca Diamond FIREBALL 2 AXLE SPHERE MACHINE User Manual

Page 9

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

START UP

Prior to placing the sphere cups on the grinding head shafts, open the moveable head to a position along

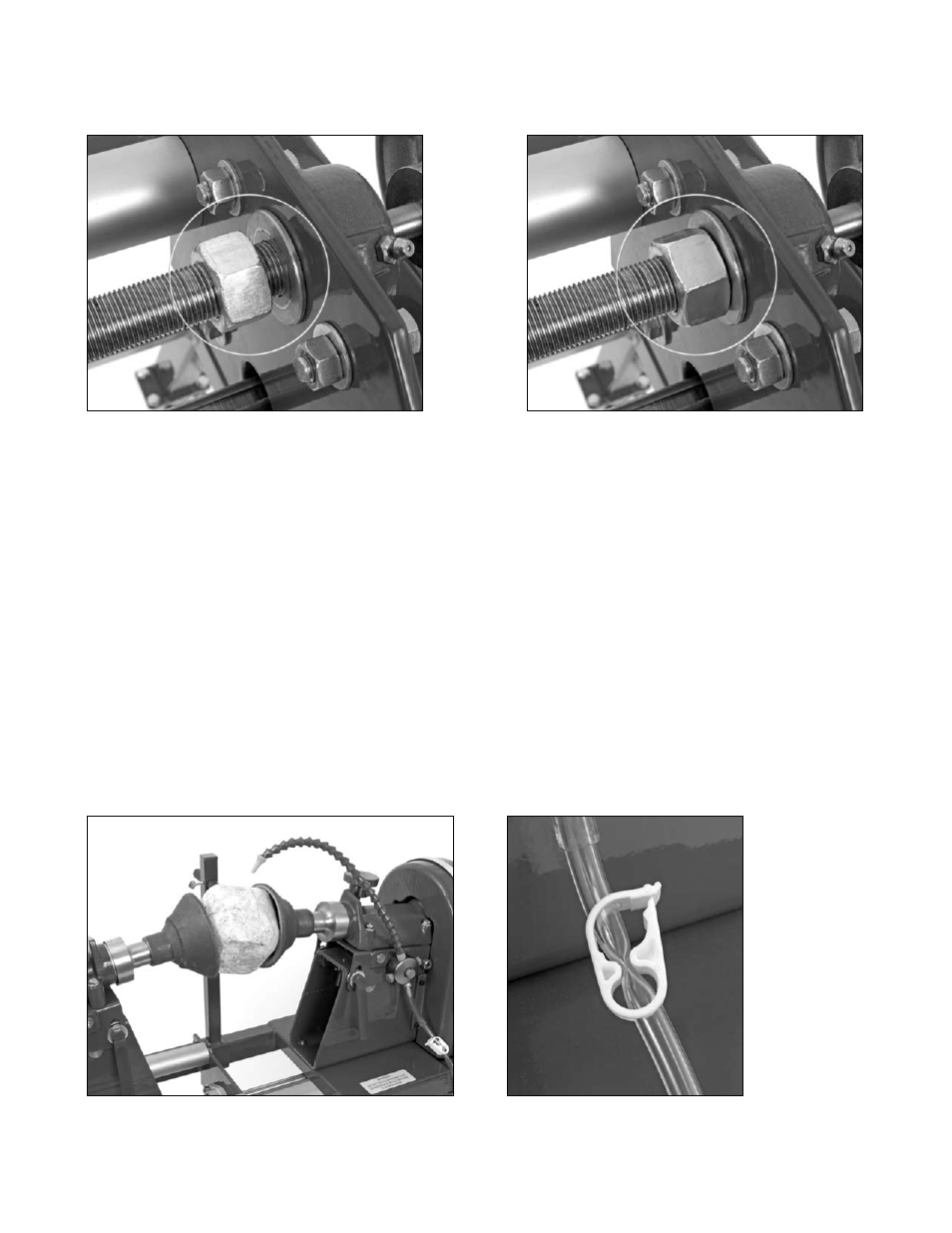

the horizontal plane of the sphere machine. This is done by first loosening the brass nut on the thread bar

adjacent to the crank handle and rotating it along the shaft a few inches (fig. 1).

Fig. 1 Brass nut loosened

Fig. 2 Brass nut tightened

This will allow free adjustment of the moveable head to the desired position. Liberally grease the head shaft

threads prior to installing sphere cups. Place a sphere cup on each of the 1/2"-13 threaded shafts of both the

fixed and moveable heads and hand tighten snuggly against the sphere cup holder face. The cups can be

tightened with use of a pipe wrench on the sphere cup shank to ensure cups are snuggly secured to the 1/2"-

13 thread (do not over tighten). Once cups are attached, place rock sphere material between cups and slowly

rotate crank wheel by hand (clockwise) stopping at a point that still allows some rotation of sphere material

between cups. Once adjusted to desired position, lock the threaded horizontal adjustment brass nut against

the plate adjacent to the crank handle (fig. 2). Do not over-tighten.

Once the sphere material is in place between the grinding cups and the moveable head is adjusted and

locked, connect the water pump to the base of the Loc-Line hose manifold and submerge the pump in a 5

gallon bucket of water. Adjust the tip of the Loc-Line nozzle to direct water flow as close to the top of the

sphere material as possible. A constant flow of water onto the sphere material must be maintained to flush

the grindings and keep the diamond cups and pads (when Velcro pad mounting cups are used) in good

condition. Any loss of water to the grinding surface of the diamond cups or polishing resin pads during use of

the machine will likely result in short diamond tool life. You can reduce or increase the waterflow to the Loc-

Line nozzle by adjusting the flow restrictor that crimps the clear tubing between the Loc-Line assembly and

the water pump.

Loc-Line hose in position

Waterflow restrictor